IAI America MSEP User Manual

Page 242

Chapter 6

Troubleshooting

234

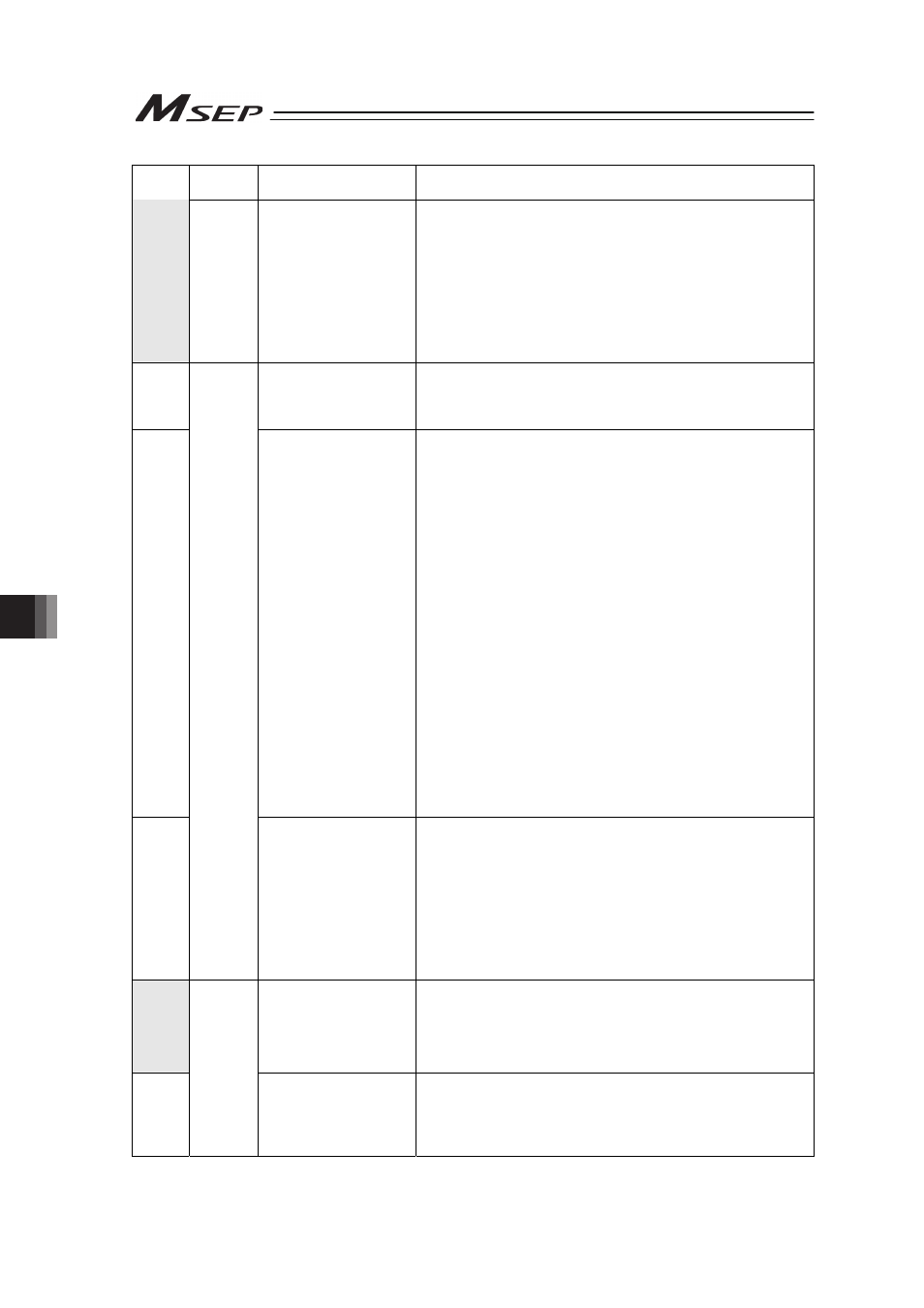

Alarm

Code

Alarm

Level

Alarm Name

Cause/Treatment

0E8

Pulse

motor

(*1)

Only

when

connected

Cold start

A- and B-phase wire

breaking

Cause

: Encoder signals cannot be detected correctly.

1) Wire breakage or connector connection error on

an actuator cable or cable enclosed in an

actuator.

2) Malfunction of encoder itself.

Treatment : 1) Check if any wire breakage on a connector and

the condition of wire connections.

If the cables are in the normal condition, the

malfunction of the encoder can be considered.

Please contact IAI.

0ED

Absolute encoder error

detection 1

Cause

: The current position has changed while controller

was reading the absolute data or saving files.

Treatment : Avoid a condition that gives vibration to the

actuator.

0EE

Absolute encoder error

detection 2

Cause

: The position data cannot be detected properly in

the Simple absolute type encoder.

1) When the power is supplied for the first time to

Simple absolute type (before executing absolute

reset)

2) Voltage drop of absolute battery.

(If the detail code in the error list of the teaching

tool is 0001H.)

3) Wire breakage or connector connection error on

an actuator cable or cable enclosed in an

actuator or connector being removed and

inserted.

(If the detail code in the error list of the teaching

tool is 0002H.)

4) Changed the parameters of controller.

Treatment : 2) Supply the power for 72 hours or more and after

charging the battery enough, perform the

absolute reset operation.

If the same failure occurs often even with

enough battery charge, it is considered the end

of the battery life. Replace the battery.

Conduct an absolute reset for 1), 2) and 4).

[Refer to Chapter 4. Absolute Reset and Absolute

Battery]

0EF

Operation

release

Absolute encoder error

detection 3

The encoder for the Simple absolute type cannot detect the

position information properly. (Encoder over speed error)

Cause

: The current position changed with a speed more

than the rotation speed setting by an external

cause during the power shutoff.

Treatment : Set the rotation speed to a higher speed than what

currently is. If the same failure occurs again, it is

necessary to have an absolute reset.

[Refer to Chapter 4. Absolute Reset and Absolute

Battery]

0F0

Servo

motor

(*2)

Only

when

connected

Driver logic error

Cause

: Exceeded load, parameter (motor type)

mismatched, noise, malfunction of controller, etc.

Treatment : Please contact IAI.

0F4

Cold start

Mismatched PCB

The PCB is not applicable for the connected motor in the startup

check.

Cause

: There is a possibility of mismatch between the

actuator and controller. Check the model codes.

Treatment : Should this error occur, please contact IAI.

(*1) Pulse motor : RCP2, RCP3, RCP4 Series

(*2) Servo motor : RCA, RCA2, RCL Series