IAI America MSEP User Manual

Page 239

Chapter 6

Troubleshooting

231

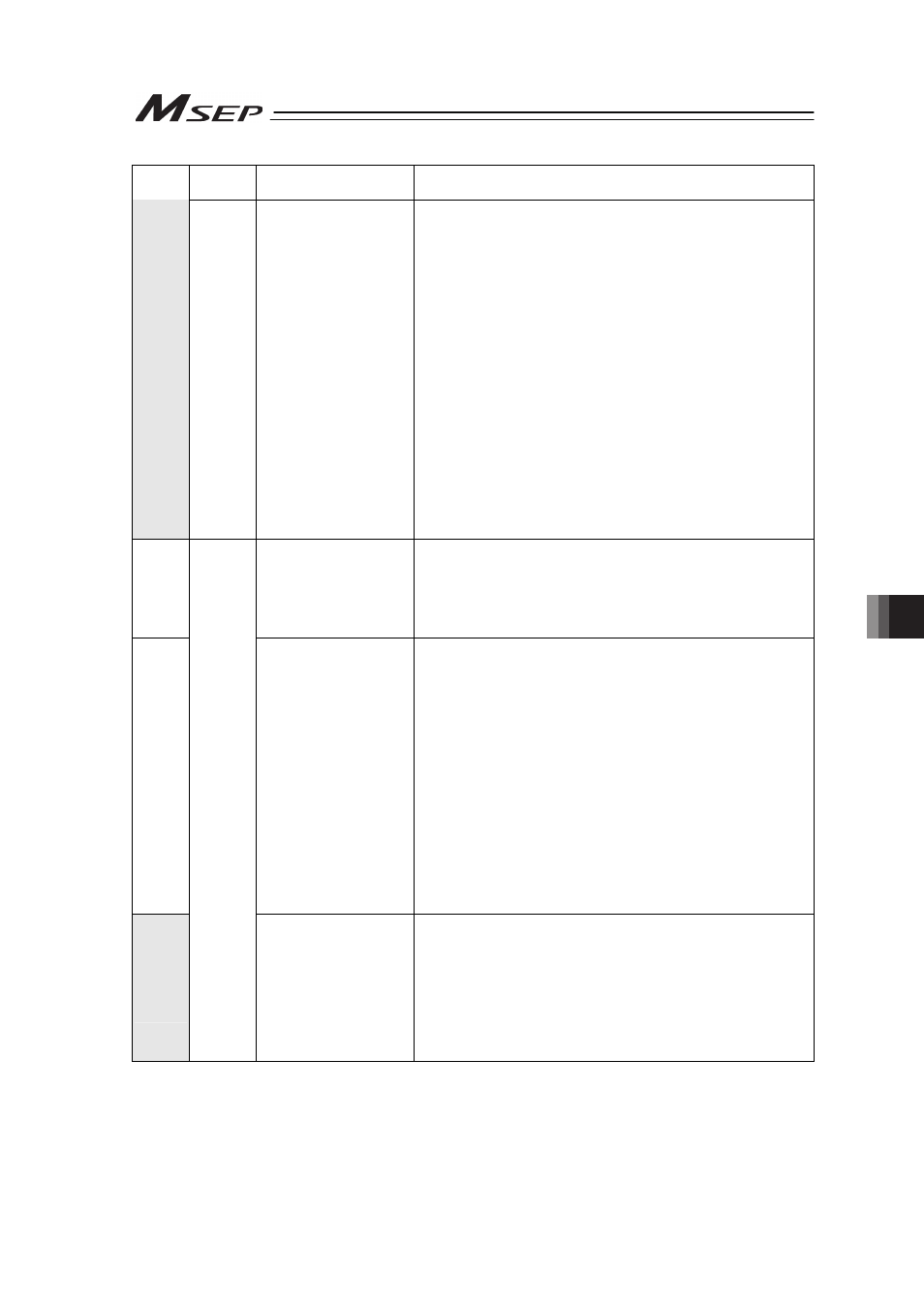

Alarm

Code

Alarm

Level

Alarm Name

Cause/Treatment

0C1

Pulse

motor

(*1)

Only

when

connected

Operation

release

Servo error

Cause

: It indicates 2 seconds has passed without making a

move since a move command was received.

1) Connection error or wire breakage on an

actuator cable

2) Brake is not released (when equipped with a

brake).

3) Load to the motor is high due to external force.

4) The resistance in the actuator sliding operation

is large.

Treatment : 1) Check the wiring condition of the actuator

cables.

2) If an improvement can be confirmed when 24V

DC, 150mA is supplied to BKRLS terminal in the

external brake input connector, a malfunction of

the controller can be considered. Please contact

IAI.

3) Confirm that there is no error in the mechanical

part assembly condition.

4) Move the slider or the rod to a point where it

would not hit the mechanical end and reboot the

system.

0C8

Overcurrent

Cause

: The output current in the power circuit section is

increased abnormally.

Treatment : This alarm will not be generated in normal

operation. Degradation in insulation of motor coil or

malfunction controller can be considered. Please

contact IAI.

0CA

Overheat

Cause

: This indicates overheat (90qC or more) of the

components inside the controller.

1) Operation is performed with the load condition

exceeding the specified range.

2) High temperature around the controller.

3) Load to the motor is high due to external force.

4) A faulty part inside the controller.

Treatment : 1) Revise the operation condition such as

decreasing the acceleration/deceleration speed.

2) Lower the ambient temperature of the controller.

3) Confirm that there is no error in the mechanical

part assembly condition.

(Note) This error would not normally occur. If it occurs,

confirm there is not (1) to (3) above. If the same

problem occurs again even with the process above,

malfunction of controller can be considered. Please

contact IAI.

0CB

Servo

motor

(*2)

Only

when

connected

Cold start

Current sensor offset

adjustment error

Cause

: An error was found to the sensor in the status check

of the current detection sensor conducted at the

initializing process in the startup.

1) A breakdown of the current detection sensor or

peripheral component is supposed.

2) An error in the offset adjustment is supposed.

Treatment : A work (PC board) change or offset adjustment is

required.

Please contact IAI.

(*1) Pulse motor : RCP2, RCP3, RCP4 Series

(*2) Servo motor : RCA, RCA2, RCL Series