3 alarm codes for driver board (each axis) – IAI America MSEP User Manual

Page 235

Chapter 6

Troubleshooting

227

6.4.3

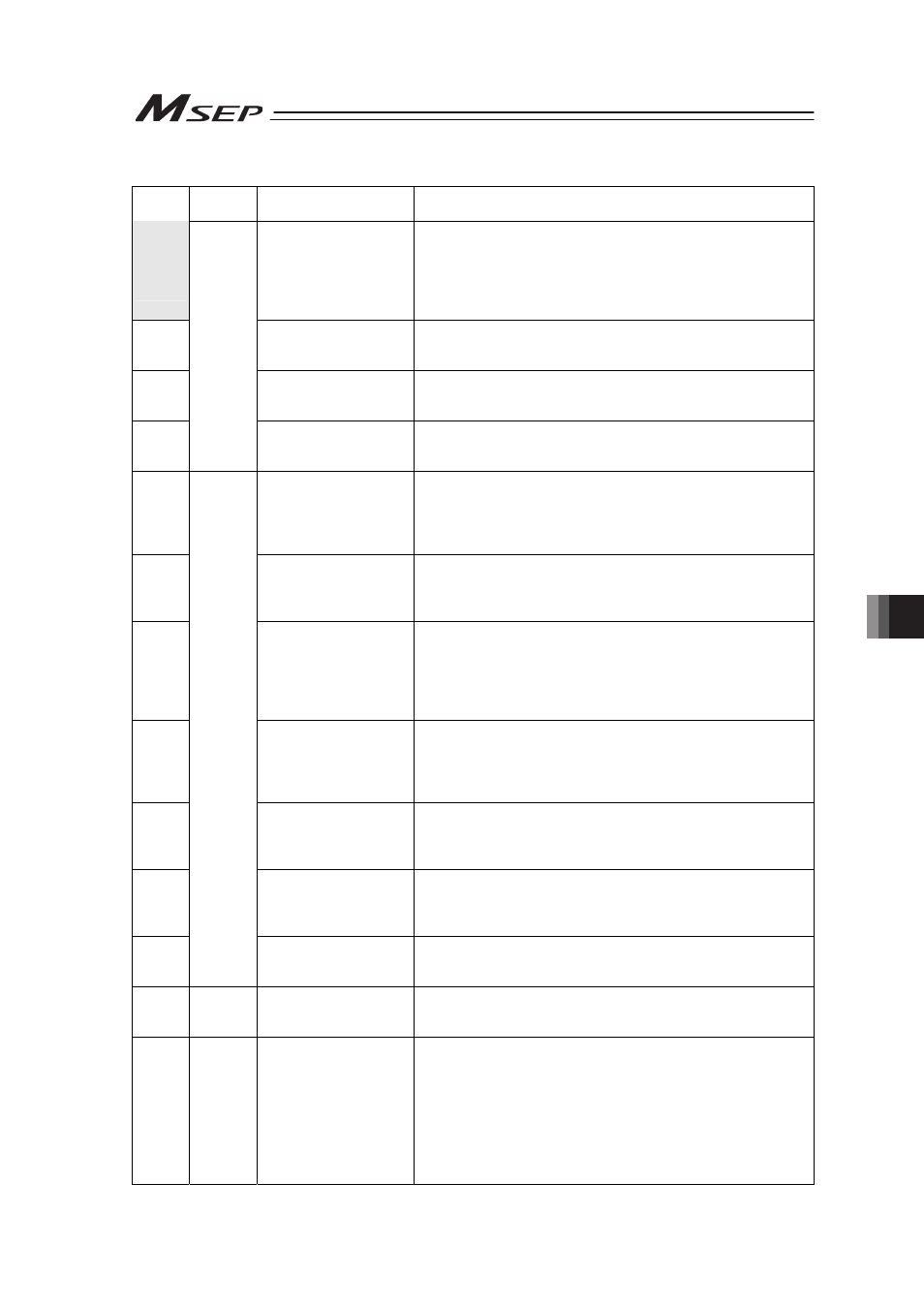

Alarm Codes for Driver Board (Each Axis)

Alarm

Code

Alarm

Level

Alarm Name

Cause/Treatment

048

Servo

motor

Only

Driver overload alarm

Cause

: There is a risk of overload with the current operation

condition.

This alarm keeps its status until a reset is

conducted.

Treatment : Lower the setting of acceleration/deceleration. Also,

increase the frequency of pause.

04E

Exceeded movement

count threshold

Cause

: The total number of the operation times exceeded

the value set in Parameter No.26 “Total Movement

Count Threshold”.

04F

Exceeded operated

distance threshold

Cause

: The total number of the operation distance

exceeded the value set in Parameter No.27 “Total

Operated Distance Threshold”.

06B

Message

Maintenance

information data error

Cause

: The maintenance information (total movement

count, total operated distance) is lost.

Treatment : Please contact IAI.

080

Move command in servo

OFF

Cause

: A move command was issued when the servo is

OFF.

Treatment : Issue a movement command after confirming the

servo is ON (servo ON signal (SV) or position

complete signal (PEND) is ON).

082

Position command in

incomplete home return

Cause

: A position move command was issued before home

return was completed.

Treatment : Issue a command after confirming that home return

has been completed (HEND) is ON.

083

Numerical command in

incomplete home return

Cause

: An absolute position command was issued by

numerical specification before home return was

completed (direct command from Field Network).

Treatment : Issue a numeric specification after performing home

return operation and confirming the complete signal

(HEND).

084

Absolute position move

command when home

return is not yet

completed

Cause

: A move command was issued when home return

was still in progress.

Treatment : Issue a movement command after performing home

return operation and confirming the complete signal

(HEND).

085

Position No. error during

movement

Cause

: A non-existing (invalid) position number was

specified in the positioner mode.

Treatment : Check the position table again and indicate an

effective position number.

090

Software reset during

servo ON

Cause

: A software reset command was issued when the

servo was ON.

Treatment : Issue a software reset command after confirming

that the servo is OFF (SV signal is 0).

091

Operation

release

Position No. error in

teaching

Cause

: The position number out of the available range was

selected in the teaching.

Treatment : Select the position number from 255 or smaller.

0A1

Cold start

Parameter data error

Cause

: The data input range in the parameter area is not

appropriate.

Treatment : Change the value to the appropriate one.

0A2

Operation

release

Position data error

Cause

: 1) A move command was input when no target

position was set in the “Position” field of a

position No. in the position table.

2) The value of the target value in the “Position”

field exceeded the Parameter No.15 “Soft limit

set value”.

Treatment : 1) Set the target position.

2) Change the target position value to the one

within the soft limit set value.