IAI America MSEP User Manual

Page 116

3.4 Fieldbus

Type

Address Map

108

(2) Input and Output Signal Assignment for each Axis

The I/O signals for each axis consists of 4-word for each I/O bit register.

Ɣ The control signals and status signals are ON/OFF signals in units of bit.

Ɣ For the target position and current position, 2-word (32-bit) binary data is available and values

from -999999 to +999999 (unit: 0.01mm) can be used. Negative numbers are to be dealt with

two’s complement.

Caution:

• Set the position data in the range of the soft stroke (0 to effective stroke length) of the

actuator.

• It is not necessary to have this setting done for Positioner 1 Mode.

Ɣ For the indicated position number and complete position number, 1-word (16-bit) binary data

is available and values from 0 to 255 can be used.

Caution:

Set the operational condition in advance with using a teaching tool such as PC software in the

position number to be used. Selecting a position number with no setting conducted will

generate the alarm code 0A2 “Position Data Error”.

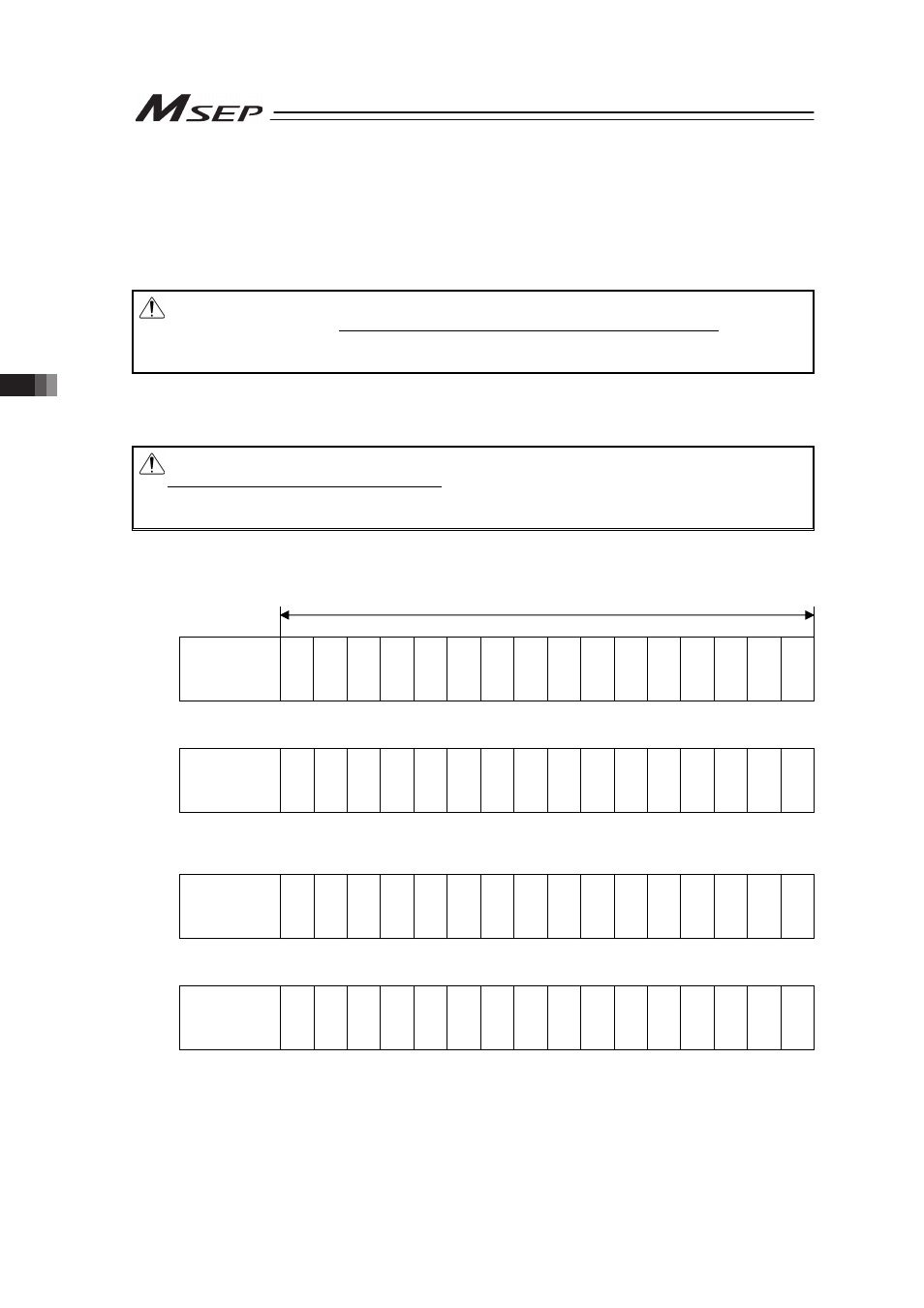

PLC Output (m is PLC output top word address for each axis number)

䎃

Address m

b15 b14 b13 b12 b11 b10 b9

b8

b7

b6

b5

b4 b3 b2 b1

b0

Target Position

(Lower word)

䎃

Address m+1

b15 b14 b13 b12 b11 b10 b9

b8

b7

b6

b5

b4 b3 b2 b1

b0

Target Position

(Upper word)

(Note) If the target position is a negative value, it is indicated by a two’s complement.

Address m+2

b15 b14 b13 b12 b11 b10 b9

b8

b7

b6

b5

b4 b3 b2 b1

b0

Specified

Position No.

–

–

–

–

–

–

–

–

PC128

PC64

PC32

PC16

P

C

8

P

C

4

P

C

2

P

C

1

䎃

Address m+3

b15 b14 b13 b12 b11 b10 b9

b8

b7

b6

b5

b4 b3 b2 b1

b0

Control Signal

B

K

R

L

–

–

–

–

–

–

JO

G

+

JO

G

-

–

JI

S

L

SON

R

E

S

S

TP

HOME

CSTR

䎃

1 word = 16 bit