IAI America MSEP User Manual

Page 227

Chapter 6

Troubleshooting

219

6.2.2

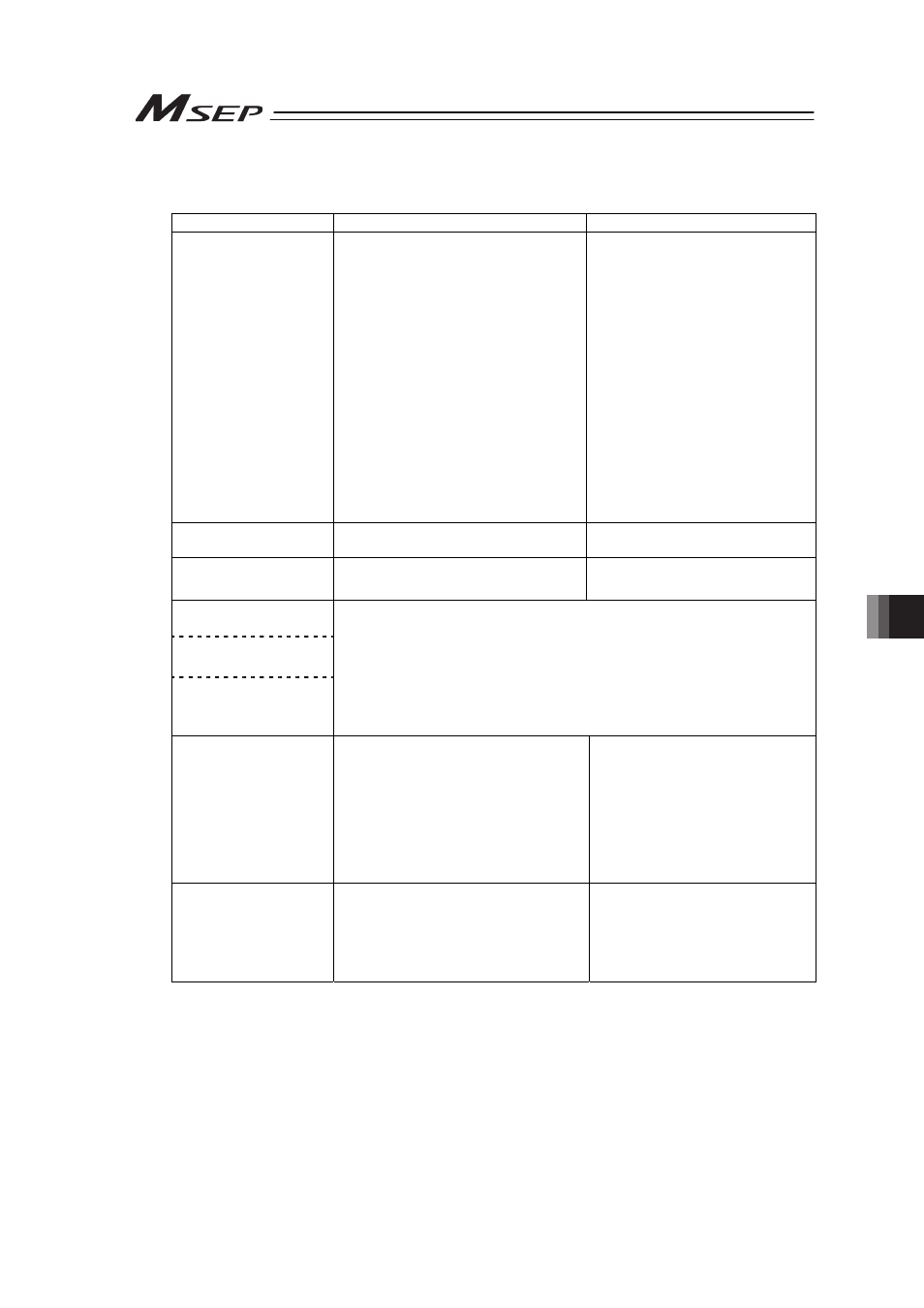

Positioning and speed of poor precision (incorrect operation)

Situation

Possible cause

Check/Treatment

Completion of operation

on the way to home

return

In the home return of our standard

specification, the actuator is first

pressed to the mechanical end, moved

oppositely, and subject to positioning

stop at the home position. Therefore,

the product may judge as the

mechanical end even though it is still on

the way when the load is large and

interfere with surrounding object.

1) A load exceeding its rating weight is

installed on the actuator.

2) It is touched to interference in the way

of the run.

3) Torsion stress is applied to guide due

to improper fixing method of the

actuator or uneven fastening of bolts.

4) The sliding resistance of the actuator

itself is large.

1) Reduce the load.

2) Remove the interference.

3) Loosen the fixing bolts once and

check whether the slider can

move smoothly.

If the slider can move smoothly,

check if there is a deformation on

the attached surface, and install

the actuator again following the

instructions stated in Instruction

Manual.

4) Please contact IAI.

Shocks at start and/or

stop.

Acceleration/deceleration is set too

high.

Decrease the settings of

acceleration/deceleration.

Overshoot during

deceleration to stop.

The load inertia is large.

Decrease the setting of

deceleration.

Positioning of poor

precision

Uneven speed during

movement

Acceleration/deceleration

not smooth (bad speed

response)

[Refer to 5.3 Servo Adjustment.]

Positioning at a position

different from that of

commanded position No.

1) For PIO Type, the start signal CSTR

after the position number command is

too early, or input at the same timing.

(Note) Inputting at the same timing is

available for Fieldbus Type.

2) The correct position No. is not

specified due to PIO signal

disconnection or poor connector

contact.

1) The stop position may be set for

another purpose. Make sure to

complete the reading of the

position numbers to this controller

before inputting the start signal.

2) Check the input signal on I/O

monitor on the teaching tool.

Complete signal PEND is

not output even though

positioning process is

completed.

Start signal CSTR is not turned OFF.

Make the start signal CSTR turned

OFF before completing the

positioning process by the turn-off

of positioning complete signal

PEND after starting operation, and

so on.