2 fault diagnosis, 1 impossible operation of controller – IAI America MSEP User Manual

Page 226

Chapter 6

Troubleshooting

218

6.2 Fault Diagnosis

This section describes faults largely divided into three types as follows:

(1) Impossible operation of controller

(2) Positioning and speed of poor precision (incorrect operation)

(3) Generation of noise and/or vibration

(4) Communication not established

6.2.1

Impossible operation of controller

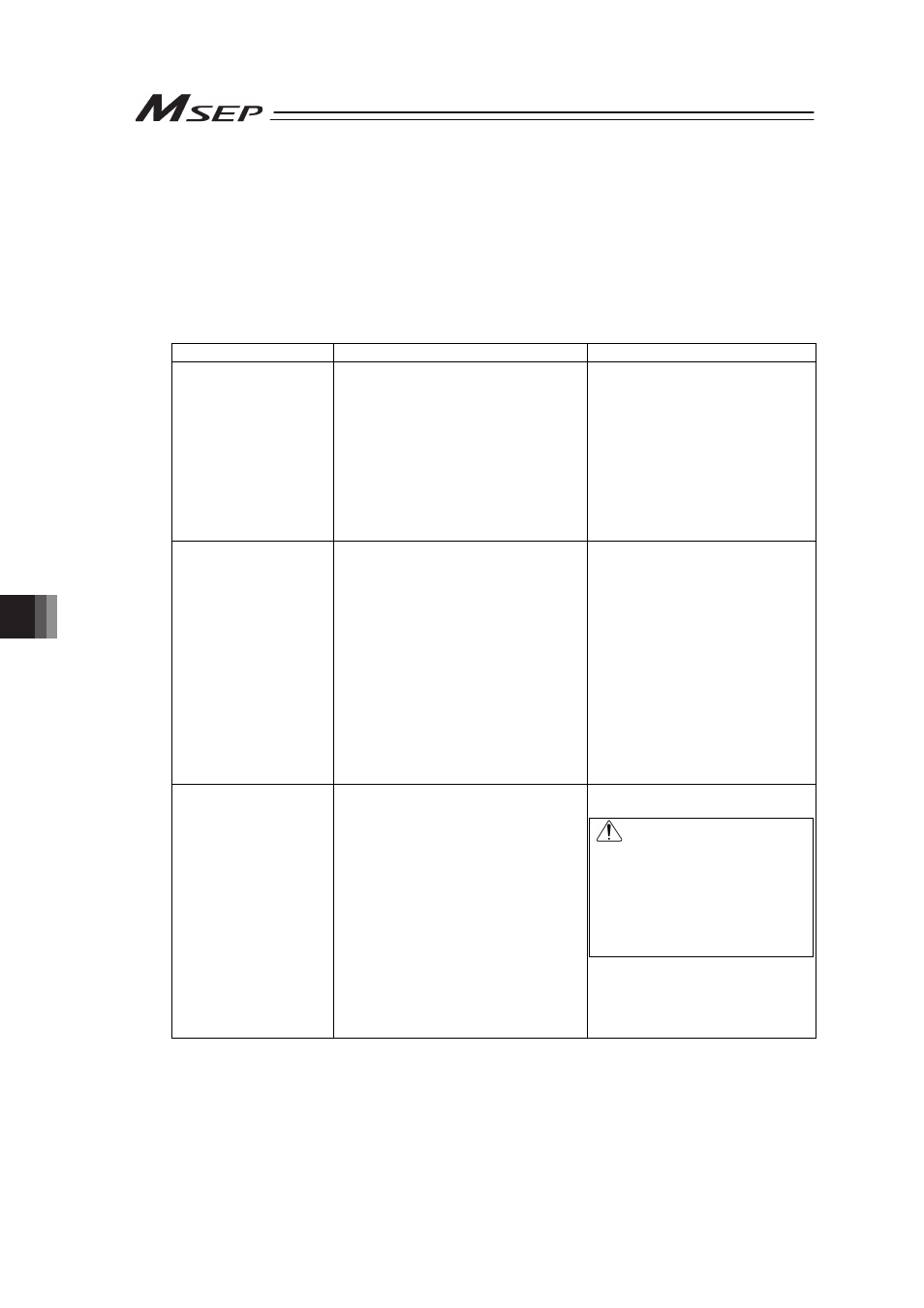

Situation

Possible cause

Check/Treatment

SYSLED or SYS I/SYS II

LED on driver board turn

ON in red when power is

supplied

(1) Occurrence of alarm.

(2) During emergency-stop.

1) Was the emergency-stop switch

released?

2) EMG- on the system I/O

connector is not connected.

(1) Check the error code with the

teaching tool being connected

and remove the cause by

referring the alarm list.

[Refer to 6.4 Alarm List.]

(2) 1) Release the emergency stop

switch.

2) Check the connection of the

system I/O connector (EMG-).

[Refer to 2.3 [1] Power Supply

and Emergency Stop]

Both position No. and

start signal are input to

the controller, but the

actuator does not move.

1) Servo OFF condition.

2) The pause signal is OFF.

3) Positioning command is issued to a

stop position.

4) There is no positioning data set to the

commanded position number.

5) Writing the information in a wrong

area for Direct Indication Mode.

1) Are SYS I/SYS II LEDs on the

driver board that the operated

axes are connected turned ON?

[Refer to Name for Each Parts

and Their Functions]

Turn ON the servo-on signal

SON.

2) Operation is available when

pause signal *STP is ON and

pause when it is OFF. Turn it ON.

3) Check the sequence or the

settings of the position table.

4) It will generate Alarm Code 0A2

“Position Data Error”. Conduct the

position table setting.

Connected the teaching

tool and supplied the

motor and control power

to controller, but

operation would not start.

(the emergency stop

switch is released on the

teaching tool)

Cable treatment or mode selection.

1) Emergency stop condition

2) Servo OFF condition

3) In pause

1) Supply 24V DC to EMG- terminal

of the system I/O connector.

Warning

If the process of 1) is conducted,

put back the setting as soon as

the adjustment work is finished.

Starting the operation without

putting it back may cause a

serious accident since the

emergency stop is set invalid.

2) 3) Put the operation mode switch

on the front panel of the

controller to “MANU” side, and

select the teach mode on the

teaching tool.