IAI America MSEP User Manual

Page 231

Chapter 6

Troubleshooting

223

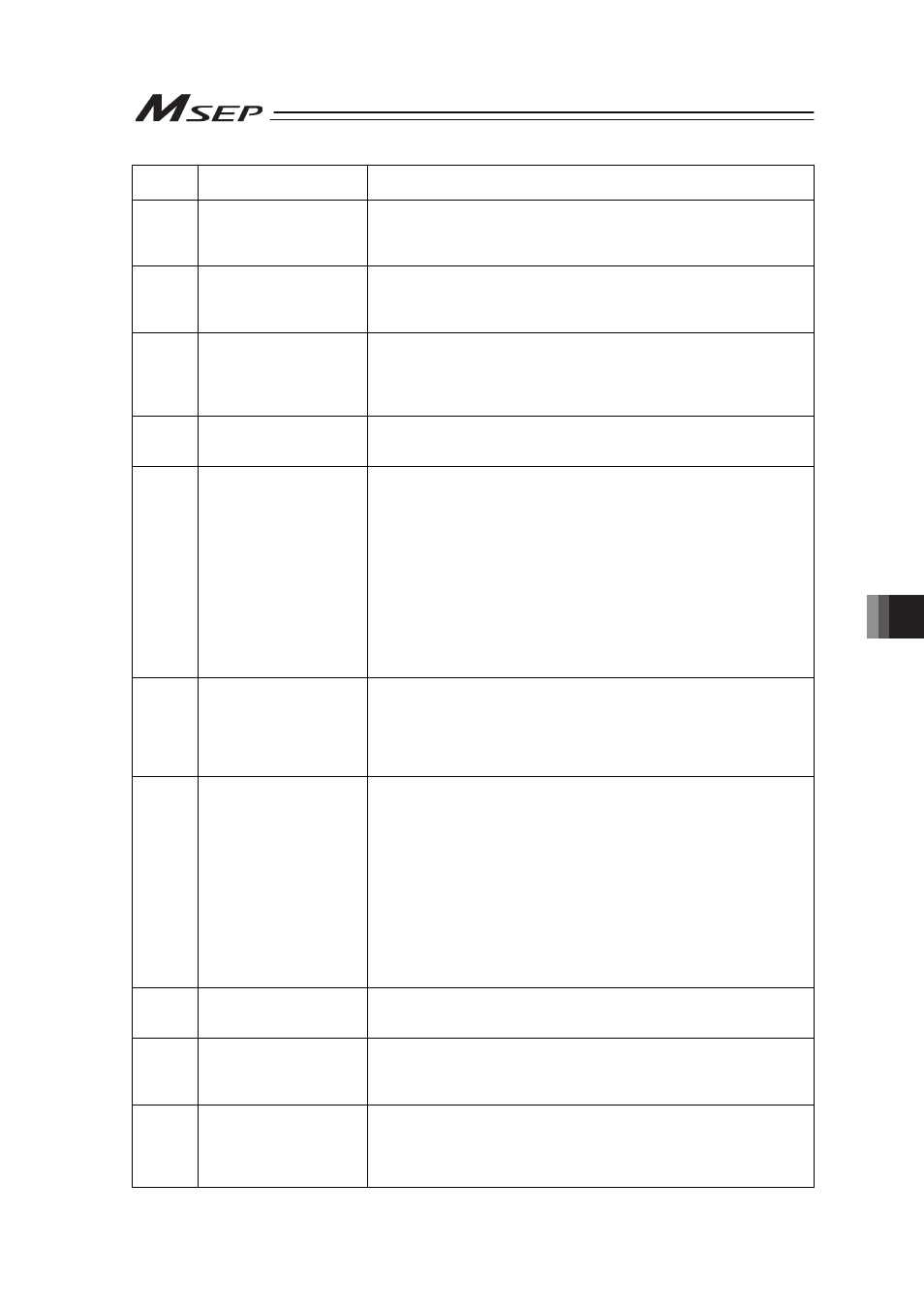

Alarm

Code

Alarm Name

Cause/Treatment

81

Parameter Check Sum

Error

Cause

: There is a possibility that the memory data inside MSEP

has destroyed.

Treatment : Establish all the settings again on Gateway Parameter

Setting Tool or write the backup data if it exists.

90

Driver Board Mount Error Cause

: The number of axes (number of driver boards) set in

Gateway Parameter Setting Tool does not match with the

number of the actually connected axes.

Treatment : Match the numbers of the axes.

9C

Fieldbus Module Not

Detected

Cause

: Communication board for Fieldbus was not detected.

1) Communication board is not inserted.

2) Malfunction of communication board

Treatment : Turn the power OFF and reboot. If the same error occurs

again, please contact IAI.

9E

Fan Error

Cause

: A Fan error was detected.

Treatment : It is considered that it is the end of the product life of the fan

(approximately 3 years). Replace the fan.

A0

Control Power

Overvoltage

Cause

: Control power voltage reached beyond the overvoltage

threshold (120% of 24V DC = 28.8V).

1) The voltage of 24V DC power supply is high.

2) A faulty part inside the controller

3) Turning the servo ON at acceleration/deceleration

spends a huge current consumption transiently. Using

the remote sensing function with a power supply with no

enough current capacity may cause overvoltage

responding to the current change.

Treatment : 1) 2) Check the voltage of the input power supply.

3) Think to use a power supply with enough current

capacity or not to use the remote sensing function.

If the voltage is normal, please contact IAI.

A1

Control Power Voltage

Drop

Cause

: The control power voltage dropped less than the voltage

drop threshold (70% of 24V DC = 16.8V).

1) The voltage of 24V DC power is low

2) A faulty part inside the controller

Treatment : Check the power voltage.

If the voltage is normal, please contact IAI.

A2

Motor Power Voltage Error Cause

: 1) Motor power input voltage (input to MPI terminal) is too

large (38V or more)

Turning the servo ON at acceleration/deceleration

spends a huge current consumption transiently. Using

the remote sensing function with a power supply with no

enough current capacity may cause overvoltage

responding to the current change.

2) Overcurrent is generated on the motor power supply line

Treatment : 1) Check the power voltage input to MPI terminal. Think to

use a power supply with enough current capacity or not

to use the remote sensing function.

2) Check the wire layout between the actuator and

controller.

A6

Encoder Voltage Drop

Cause

: The power voltage for the encoder has dropped below the

allowable range.

Treatment : Check the connection between the actuator and MSEP.

AA

Regenerative Electric

Discharge Circuit Error

Cause

: There is an error in the regenerative discharge circuit inside

the controller.

Treatment : Turn the power OFF and reboot. If the same error occurs

again, please contact IAI.

AB

Assumed Regenerative

Discharge Excessive

Power

Cause

: The regenerative electric power exceeded what can be

dealt with the regenerative resistor.

Treatment : Decrease the acceleration/deceleration speed, revise the

operation interval or connect an external optional

regenerative resistor (RER-1).