Pressure calibration, Pressure calibration -19 – TeeJet Legacy 6000 CAN Guide User Manual

Page 89

Fieldware for the Legacy 6000

Software Version 2.11

Chapter 3 - Real-time Setup

3-19

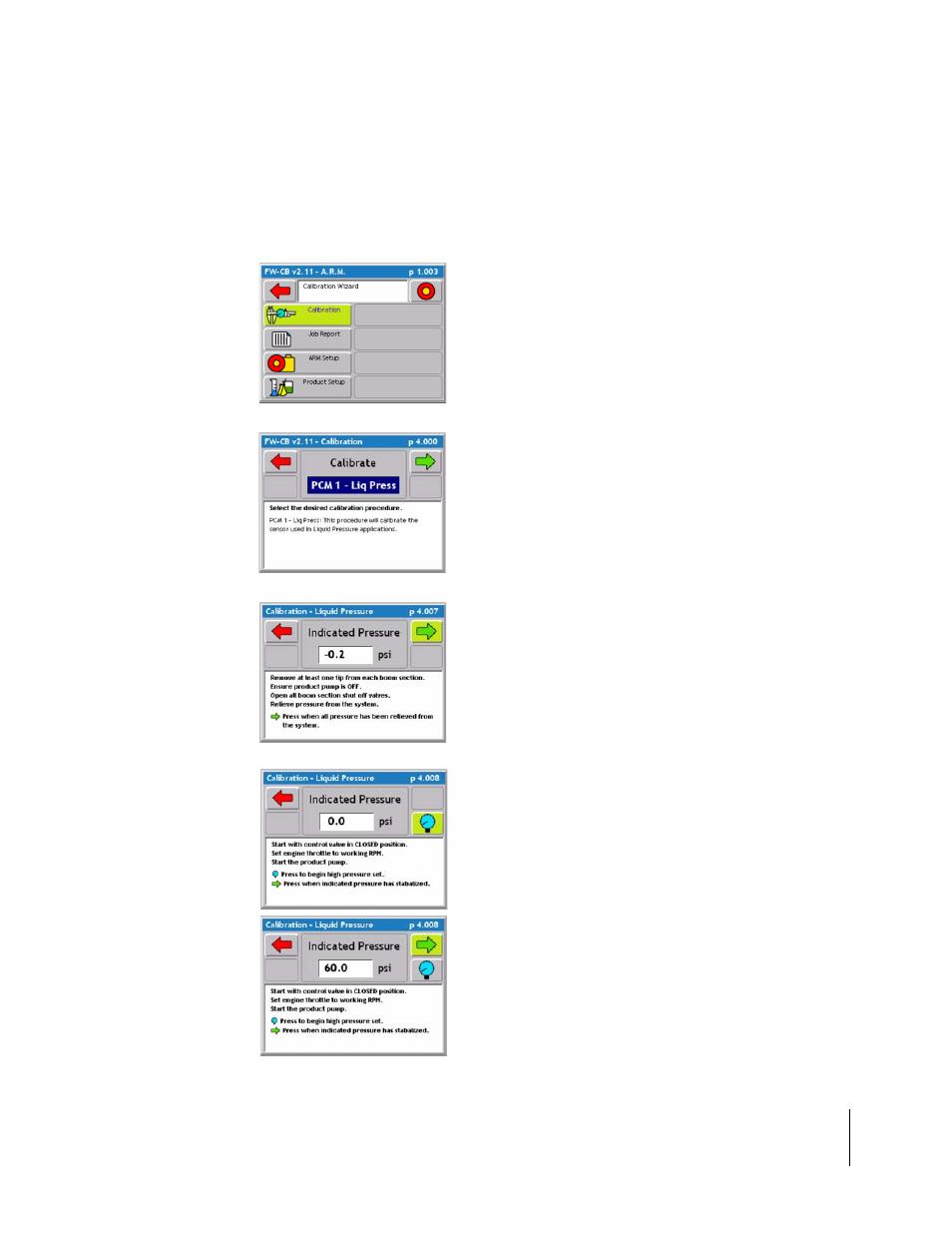

Performing a Calibration

Pressure Calibration

The Pressure Calibration process is a stationary calibration for a pressure sensor. This procedure

involves the discharge of material for the most accurate calibration. The use of water is recom-

mended when calibrating.Repeating calibration procedure will ensure accurate calibration.

1. Fill machine with enough water to perform calibration

and have a manual pressure gage mounted in-line with

the booms. The most ideal location for a manual pres-

sure gage is as close to the boom delivery point as pos-

sible. From the ARM Launcher page select the

Calibration button by using the function key or by high-

lighting Calibration and pressing the green enter button.

2. From the Calibration page select the PCM - Liq-

Press option from the pick list in the middle of the

screen. Press the green forward arrow to continue to

the next calibration step.

3. Indicated Pressure low is the current pressure read-

ing on the system. This reading should be zero. With

the product pump off open all boom valves and

remove at least one to relieve pressure from the sys-

tem. When pressure has been relieved press the

green forward to set a zero value and to continue to

the next calibration step.

4. Indicated Pressure high (max operating pressure) is

the high pressure reading at normal operation. Start

with all booms on and the control valve closed. Set

engine throttle to working RPM and start product

pump. Press the blue pressure gage button to begin

high pressure setting, the control valve will fully open

and product will be discharging out the boom. When

the pressure stabilizes, read and record the pressure

from the manual gage, and press the green forward

arrow to continue to the next calibration step.