Primary sensor settings, Table 2-14: primary sensor settings, Primary sensor settings -31 – TeeJet Legacy 6000 CAN Guide User Manual

Page 59: Sensor settings definition

Fieldware for the Legacy 6000

Software Version 2.11

Chapter 2 - Getting Started

2-29

Product Control Module (PCM) Setup

Primary Sensor Settings

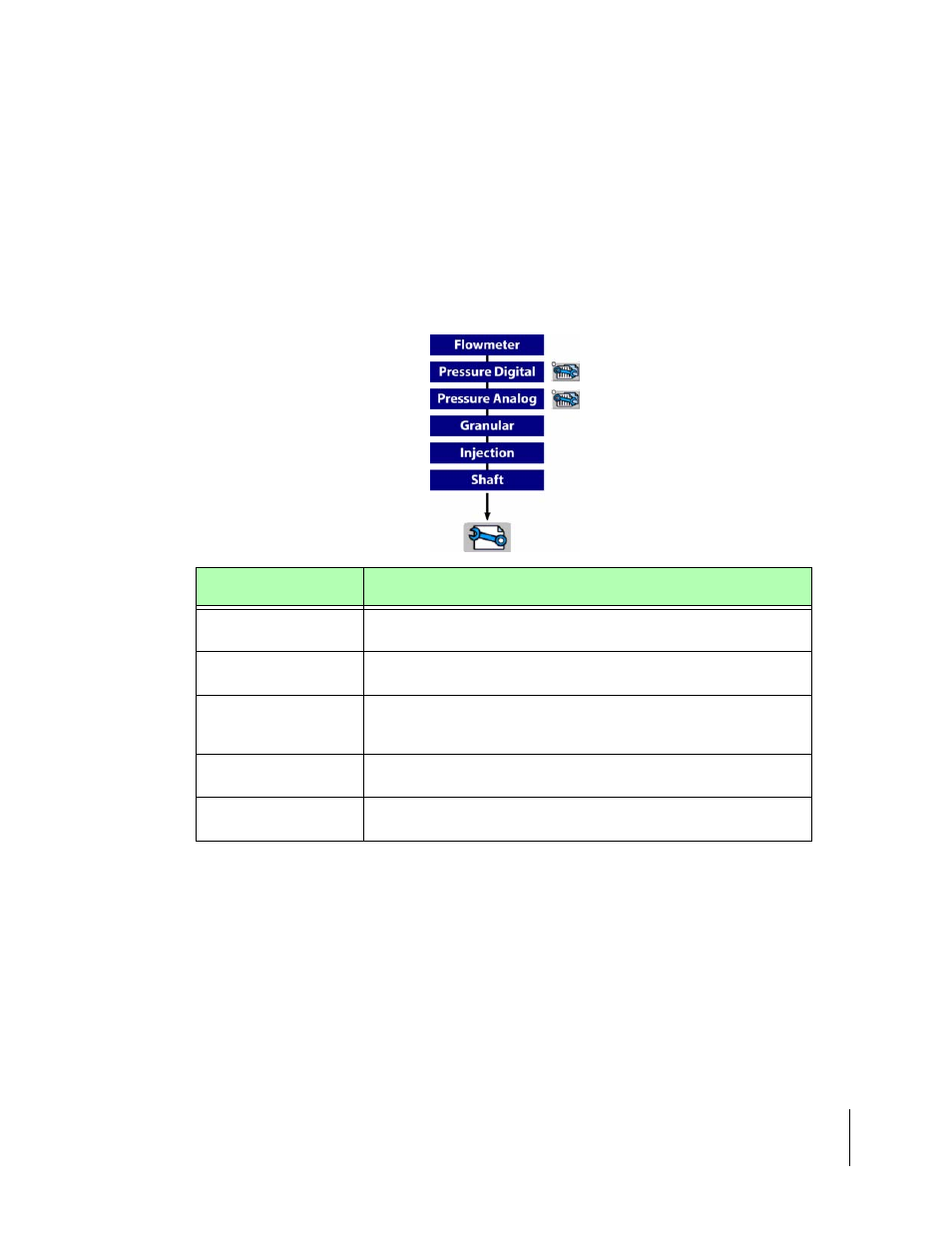

Primary Sensors Flowmeter, Granular, Injection and Shaft have detailed settings that are the

same. Review (Table 2-7) for a detailed description of the settings. The two other Primary Sensors,

Pressure Digital and Pressure Analog, have the initial settings as well as an sub settings. To

access the sub settings locate the two Settings Buttons on the right side of the screen, use the two

buttons to swap between settings.(Figure 2-32). Review (Table 2-14) for a detailed Description of

the initial settings and (Table 2-15) for a detailed description of the sub settings for Pressure Digital

and Pressure Analog senors.When the Primary Sensor settings and parameters are selected,

press the Forward arrow to advance to the next PCM Setup page

Sensor Settings

Definition

Input

Defines digital and analog sensors. Senor inputs A-D are digital (flowemeter,

and slot sensors) and Senors E-F are analog (pressure).

Sensor Name

A user defined name used to label a particular sensor or monitor. This informa-

tion is not stored in the PCM and is used for messaging to the user only.

Calibration Number

Enter calibration number in units specified, this number is normally found on

the sensor. Physical calibration will further fine-tune this number. For NH3

applications (See “Appendix C - NH3 Application” on page C-1.)

Cal# Basis

Table of preset calibration numbers. This can be used to rapidly change a cali-

bration number. See Appendix B for Cal# Basis setup.

Nozzle Constant

Only use for Pressure application. Enter the gal/min rating of your nozzle at

10mph at 30psi

Table 2-14: Primary Sensor Settings