Granular & seeder in-field calibration, Granular & seeder in-field calibration -17 – TeeJet Legacy 6000 CAN Guide User Manual

Page 87

Fieldware for the Legacy 6000

Software Version 2.11

Chapter 3 - Real-time Setup

3-17

Performing a Calibration

Granular & Seeder In-Field Calibration

The Granular In-Field Calibration process is used to calibrate a Granular sensor after a real-time

product application. In-Field calibration involves discharging a know amount of product in a real-

time application and then performing a calibration based on the material discharged. Repeating

the procedure below will ensure an accurate calibration.

1. Load machine with a know amount of product.

Record this amount for later use.

2. With the product loaded, apply the product. Make

sure before starting all accumulated volumes are zero.

This can be done by creating a new job when using a

data card or if no data card is in use select field reset

to set volumes to zero. The volume accumulated will

be used in the In-Field Calibration procedure. For best

results apply product at the rate and speed of normal

operation.

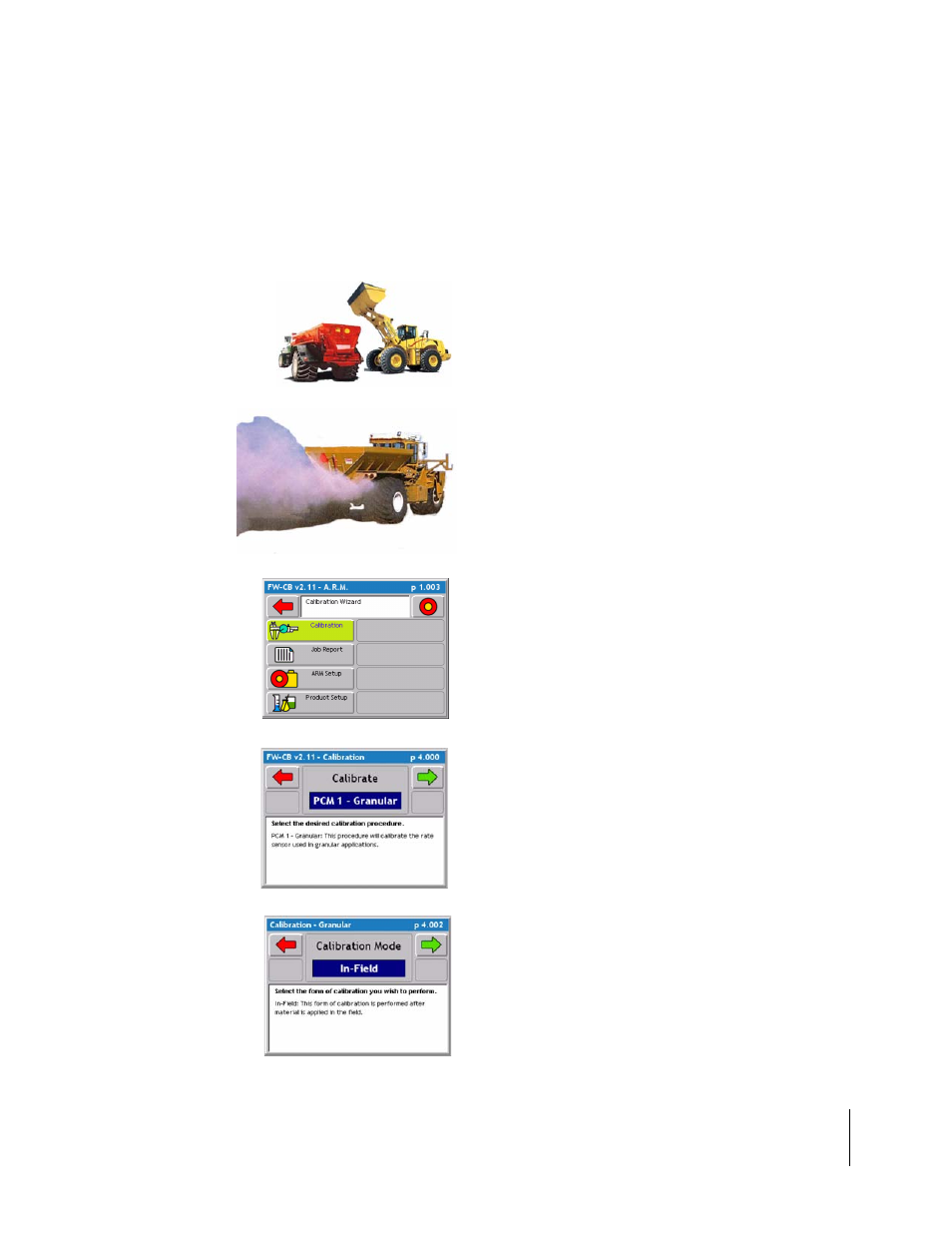

3.Once the product has been applied, from the ARM

Launcher page select the Calibration button by using

the function key or by highlighting Calibration and

pressing the green enter button.

4. From the Calibration page select the PCM -Granular

option from the pick list in the middle of the screen.

Press the green forward arrow to continue to the next

calibration step.

5. From the Calibration Mode page select In-Field from

the pick list in the middle of the screen. Press the

green forward arrow key to continue to the next cali-

bration step.

- In Field - Involves driving in a field, simulating a real

time application. -

Static - Does not require the vehicle to move. This is a

stationary test.