IAI America XSEL-S User Manual

Page 130

Chapter 3 Programs

122

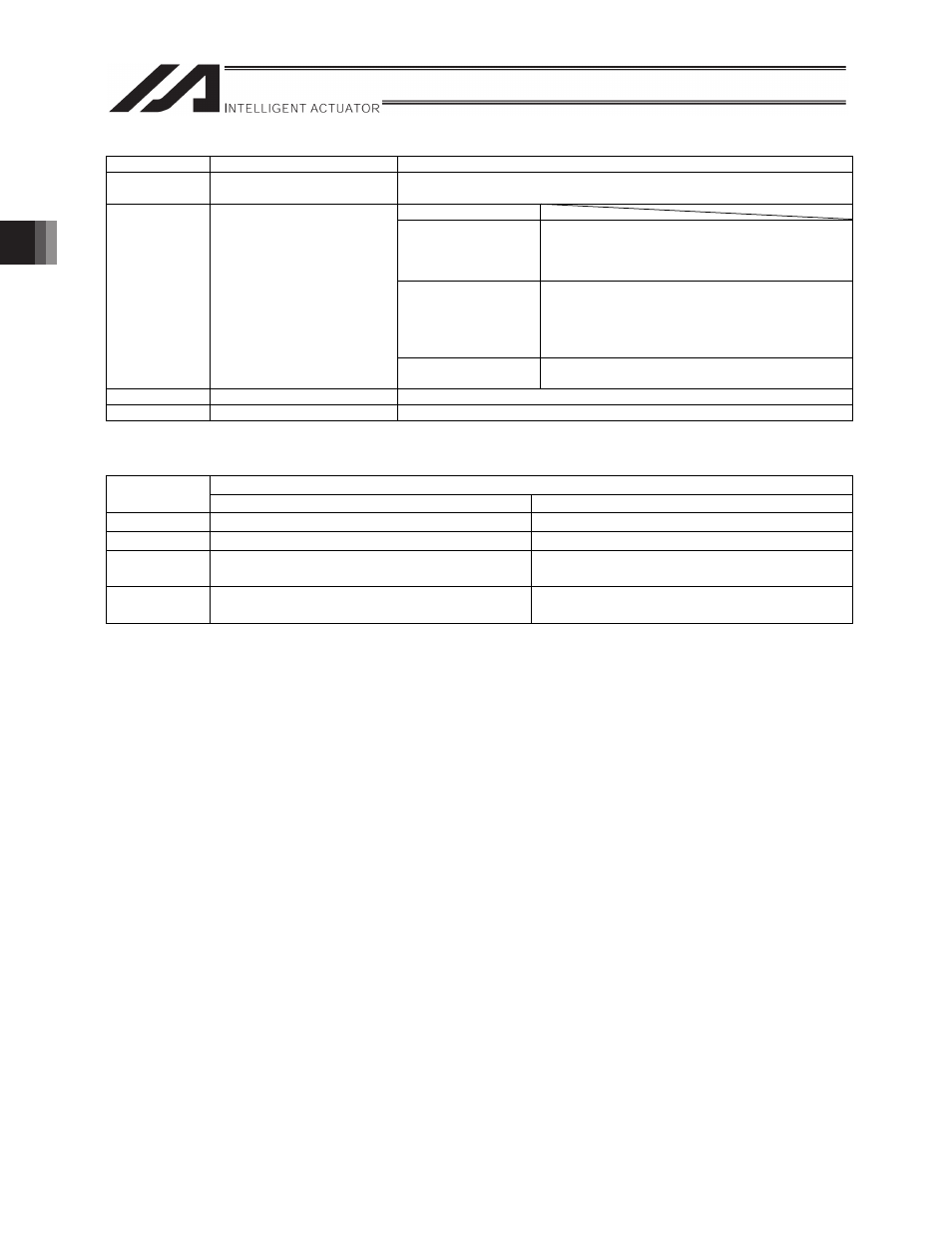

Variable No.

Data name

Description

n + 6

Slave axis stroke length

storage position No.

* Specify position No. of extension motion control board control slave axis (0

to maximum position No.)

Master axis type

0

Master axis synchronization start position storage

position No.

(Note) Specify position No. of main CPU control

master axis (0 to maximum position No.)

1

Master axis synchronization start position storage

position No.

(Note) Specify position No. of extension motion

control board control master axis (0 to

maximum position No.)

n + 7

Master axis synchronization

start position (storage position

No.)

* Valid only when “master axis

arriving specified

synchronization position” is

selected as synchronization

type

2

Master axis synchronization start position (pulse

unit)

n + 8

Reserved

Make sure to set 0.

n + 9

Reserved

Make sure to set 0.

Synchronization type (variable No. n)

Description

Setting value

Synchronization start type

Synchronous movement repeat type

0

Immediate

One cycle only

1

Immediate

Repeat

2

Master axis arriving specified

synchronization position

One cycle only

3

Master axis arriving specified

synchronization position

Repeat

Synchronous movement continues until:

[1] The XSYE command is executed (synchronous movement is stopped).

[2] The operation of slave axes is stopped (XSTP/CANC commands).

[3] The synchronous movement repetition type is single cycle only and the master axis reached the

stroke end.

[4] The slave axis movement program that executed the XCAS command is terminated.

x

The master axis stroke length/stroke end position and master axis synchronization start position shall

be set to position data of the master axis if the master axis is a main CPU control axis or extension

motion control board control axis. If the master axis is a pulse input channel, set them directly to

variables for movement settings. The slave axis stroke length is set in slave axis position data.

x

If master axis stroke end position is specified for the stroke type, the master axis stroke length (single

cycle) of electronic CAM tables becomes [master axis stroke end position – synchronization start

master axis position]. The relationship of the master axis position with electronic CAM table phases is

as follows: phase 0 corresponds to synchronization start master axis position, and the positive phase

direction is the direction to move from synchronization start master axis position toward master axis

stroke end position.

x

If master axis stroke length is specified for the stroke type, the relationship of the master axis position

with electronic CAM table phases is as follows: phase 0 corresponds to synchronization start master

axis position, and the positive phase direction corresponds to master axis coordinate positive move

direction when the stroke length has a positive coordinate value and the minus phase direction

corresponds to master axis coordinate positive move direction when the stroke length has a negative

coordinate value.