Part 3 maintenance, 1 periodic inspection items – IAI America REXT User Manual

Page 403

Part 3 Maintenance

Chapter 2 Maintenance/Inspection

371

Part 3 Maintenance

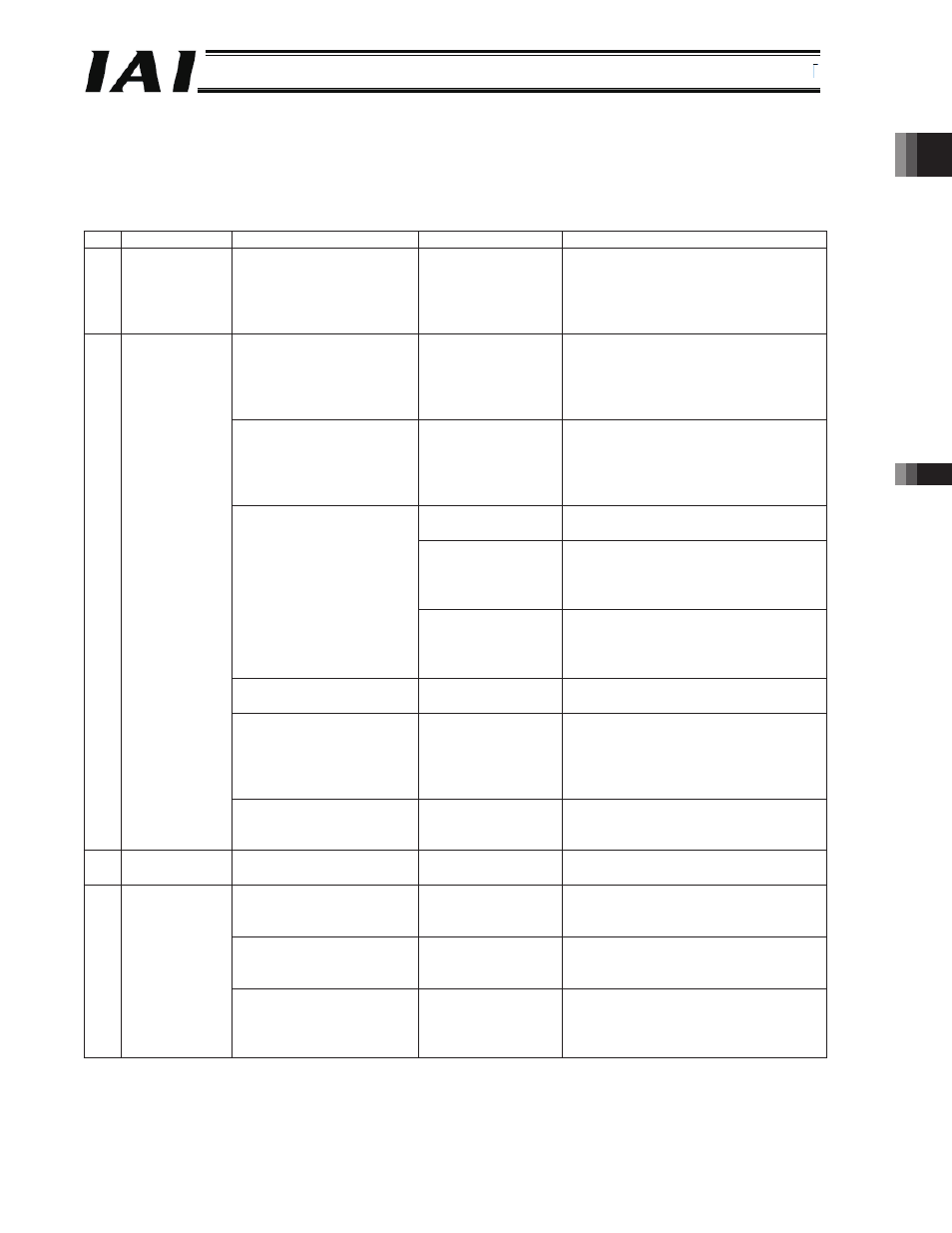

2.1 Periodic Inspection Items

The ROBONET may suffer deterioration of electronic parts or exhibit other undesirable conditions depending on the

environment. To prevent these problems, periodic inspection is necessary.

The standard inspection interval is six months to one year. Shorten the interval depending on the surrounding environment.

No. Inspection item

Description

Judgment criterion

Action

1 Supply voltage Measure the voltage at the

power-supply terminal

block to check if the voltage

fluctuation meets the

judgment criterion.

Voltage fluctuation

is within the

specified range of

24 V r 10%.

Change the settings so that the supply

voltage meets the judgment criterion.

2 Surrounding

environment

Ambient temperature

(If a panel is used, the

temperature inside the

panel represents the

ambient temperature.)

0 to 40qC

Measure the ambient temperature

using a temperature gauge and adjust

the surrounding environment so that

the measured value falls within the

ambient operating temperature range.

Ambient humidity

(If a panel is used, the

humidity inside the panel

represents the surrounding

humidity.)

95% RH or below,

non-condensing.

Measure the ambient humidity using a

hygrometer and adjust the surrounding

environment so that the measured

value falls within the ambient operating

humidity range.

Free from corrosive

or flammable gases.

Check by smell or using a gas sensor,

etc.

Not exposed to

splashes or mist of

water, oil and

chemicals.

Remove, and shield the ROBONET

from, sources of splashes/mist

Ambience

Free from deposits

of dust particles,

salt, iron powder or

other powder dust.

Remove, and shield the ROBONET

from, sources of powder dust.

Direct exposure to sunlight Not exposed to

direct sunlight.

Shield the ROBONET from direct

sunlight.

Direct transmission of

vibration or impact to the

body

Meeting the

vibration resistance

and impact

resistance

specifications.

Install cushions or other means for

withstanding vibration and impact.

Nearby noise sources

Absence of noise

sources nearby.

Move noise sources away from the

ROBONET or shield the ROBONET

from noise sources.

3 Installation

condition

Installation condition of

each unit on the DIN rail

No loosening of unit

mounting parts.

Install the unit again and lock it firmly.

4 Connection

condition

Firm connection of each

power-supply connection

plate between units

Connection plate

screws are

tightened firmly.

Retighten the screws to eliminate any

looseness.

Firm insertion of each

communication connection

board between units

Inserted completely. Insert the board again.

Firm insertion of the

connection board between

the simple absolute R unit

and controller unit

Inserted completely. Insert the board again.

-403-