Part specification – IAI America REXT User Manual

Page 28

Part 1 Specification

Chapter 1 Overview of ROBONET

Part Specification

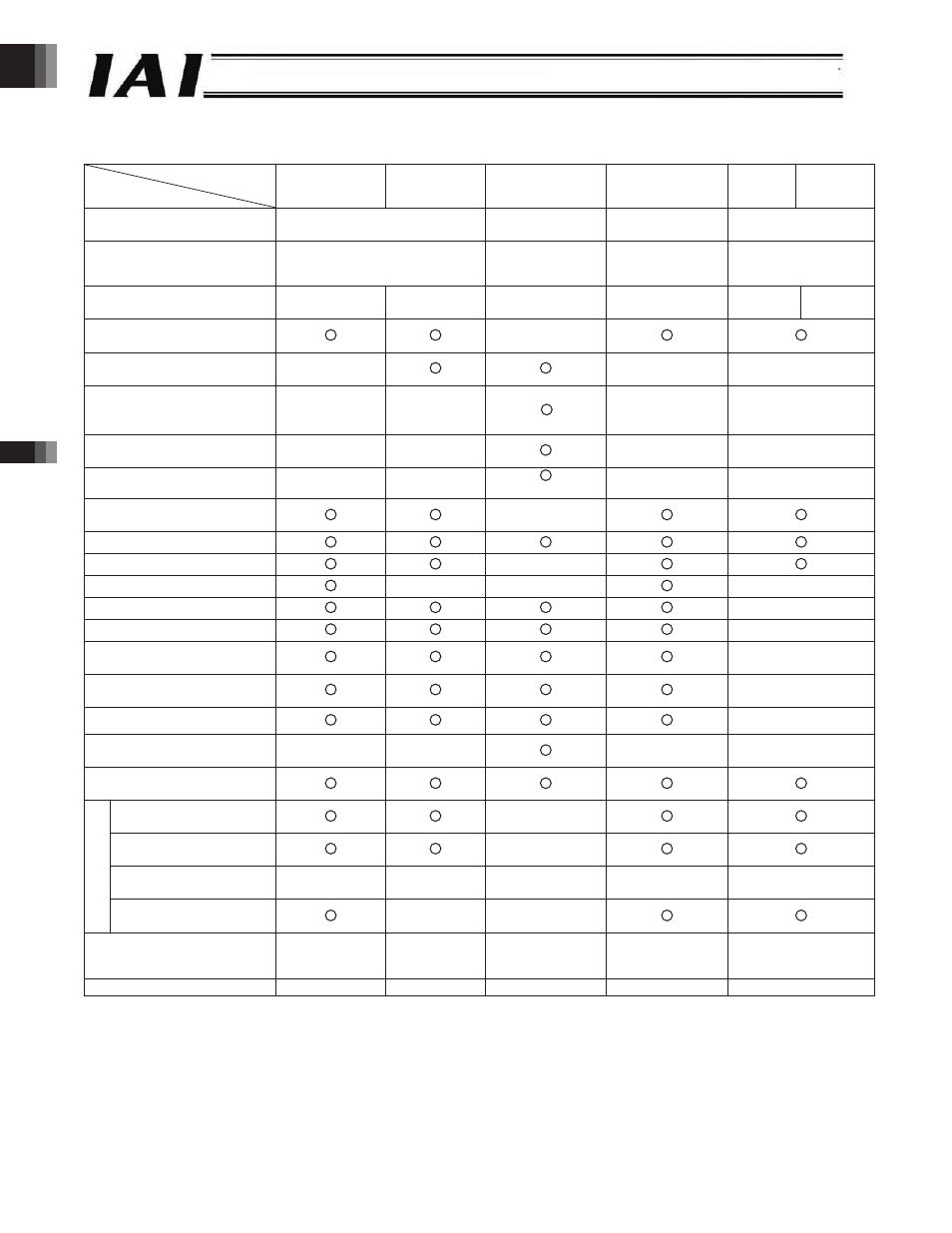

List of ROBONET Operation Functions

Operation mode

Item

Positioner mode Simple direct

mode

Direct numerical

specification mode

Positioner mode

Solenoid

valve

mode

Solenoid

valve mode

Axis area

(both input and output)

words

words

words

words

Fixed area

(both input and output)

words

(The command area can be used.)

words

(The command area

cannot be used.)

words

(The command area

can be used.)

words

(The command area can

be used.)

Number of registrable

positions

points/axis

points/axis

-

points/axis

points/axis

points/axis

Operation by position number

specification

X

Direct position data

specification

X

(Position table)

X

(Position table)

X

(Position table)

Direct speed &

acceleration/deceleration

specification

X

(Position table)

X

(Position table)

*

X

(Position table)

X

(Position table)

Direct positioning band

specification

X

(Position table)

X

(Position table)

X

(Position table)

X

(Position table)

Push operation

X

(Position table)

X

(Position table) (Direct specification)

X

(Position table)

X

(Position table)

Completed position number

monitor

X

Zone output monitor

Position zone output monitor

X

Teaching operation

X

X

X

Jogging operation

X

Inching operation

X

Various status signal monitor

*

X

Current position monitor

*

X

Alarm code monitor *

X

Speed/electrical current

monitor

* *

X

X

X

X

Axis monitor function in

AUTO mode

*

Handshake

X

Position table data

read/write

X

Current position read

X

X

X

X

X

C

omma

nd

Broadcast

X

X

Maximum specifiable position

data value

. mm

(When a

command is used)

. mm

. mm

. mm

(When a command

is used)

. mm

(When a command

is used)

Number of connectable axes

* Various status signals, current position, alarm codes and speed/electrical current can be monitored by accessing each

address of the gateway unit from the PLC.

* Before, axis monitor was not possible in the AUTO mode. This has become possible with the ROBONET, even when the

MODE switch is set to AUTO, by connecting a dedicated touch panel to the TP connector.

* Separate values cannot be set for acceleration and decelerat

* The command is monitored for speed and electrical current.

ion. The acceleration and deceleration are always the same.

-28-