Part 3 maintenance – IAI America REXT User Manual

Page 397

Part 3 Maintenance

Chapter 1 T

roubleshooting

365

Part 3 Maintenance

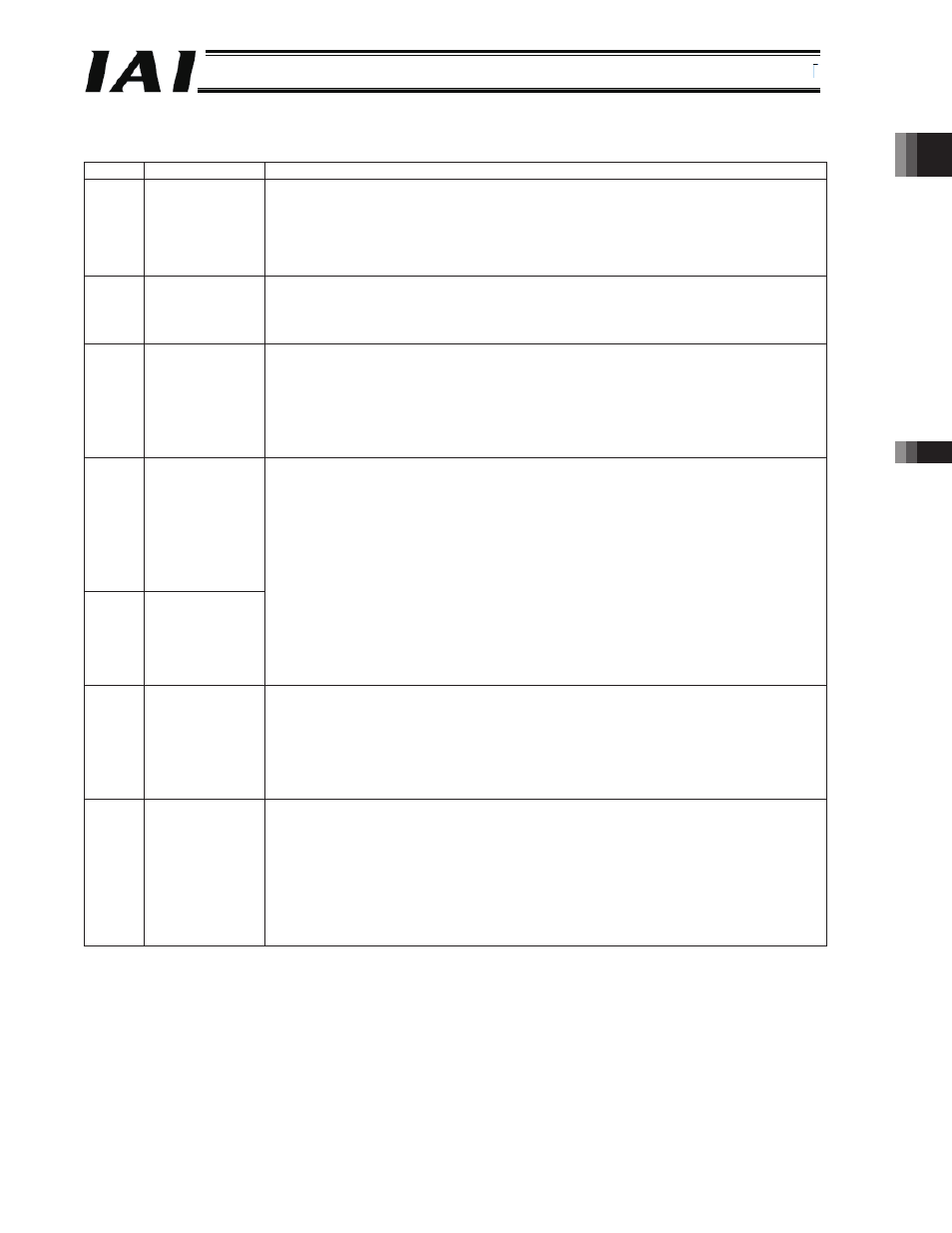

(2) Cold start level

Code

Alarm name

Cause/action

0A1 Parameter error Cause: The input range of data in the parameter area is not appropriate.

(Example) This alarm generates when the magnitude relationship of a pair of

input values is clearly inappropriate, such as when the values of

soft limit + and soft limit – were input wrongly as 200.3 mm and 300

mm, respectively.

Action: Change the input data to appropriate values.

0A8 Unsupported

motor/encoder

type

Cause: The motor type or encoder type set by a parameter is not supported.

Action: If the alarm generates again after reconnecting the power, contact IAI.

0B4 Inconsistent

electrical angle

Cause: The position deviation counter has overflowed.

Action: Check the load conditions such as whether the work part is contacting any

nearby object and whether the brake is released.

If this alarm generated before confirmation of electrical angles (while phase Z

was not yet detected), a deviation overflow may be a possibility. If this is the

case, the motor wire may be broken or output from the encoder wire may be

abnormal. Check the cable connections.

0B7 Indeterminable

magnetic pole

(RACON only)

0B8 Excitation

detection error

(RPCON only)

This controller performs magnetic-pole phase detection (pole sensing) when the servo is

turned on for the first time after the power ON. This alarm indicates that the magnetic-pole

phase could not be recognized within the specified time.

Cause: [1] Loose or disconnected motor-extension cable connector

[2] Brake cannot be released on an actuator equipped with brake.

[3] Large motor load due to application of external force

[4] Large slide resistance of the actuator itself

Action: [1] Check the wiring condition of the motor-extension cable.

[2] Check the wiring condition of the brake cable. Also, turn on/off the brake

release switch and check if the brake makes “click” sounds.

[3] Check for abnormality in the assembly condition of mechanical parts.

[4] If the payload is normal, cut off the power and move the actuator by hand to

check the slide resistance.

If the actuator itself is suspected as the cause, please contact IAI.

0C8 Overcurrent

(RACON only)

Cause: The output current from the power-supply circuit became abnormally high.

This alarm should not generate in normal conditions of use. If it does,

deterioration of motor coil isolation is suspected.

Action: Measure the line resistances between motor connection wires U, V and W, and

the isolation resistance with respect to the ground, to check for deterioration of

isolation.

If you require the above measurements, please contact IAI.

0CA Overheat

This alarm indicates that the temperature around the power transistor or regenerative

resistor in the controller is excessively high (95qC or above).

Cause: [1] The ambient temperature is high.

[2] The regenerative energy is excessive. (In the case of an actuator installed

vertically, the deceleration setting for downward movement is too high.)

[3] A faulty part inside the controller

Action: [1] Lower the ambient temperature of the controller.

[2] Review the settings and decrease the deceleration.

If [1] and [2] do not apply, please contact IAI.

-397-