2 o/i link communication settings, O/i link communication settings, 2o/i link communication settings – IDEC High Performance Series User Manual

Page 569: External device setup manual

551

2 O/I Link Communication Settings

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

O/I Lin

k

Co

mmun

ication

External Device Setup Manual

2

O/I Link Communication Settings

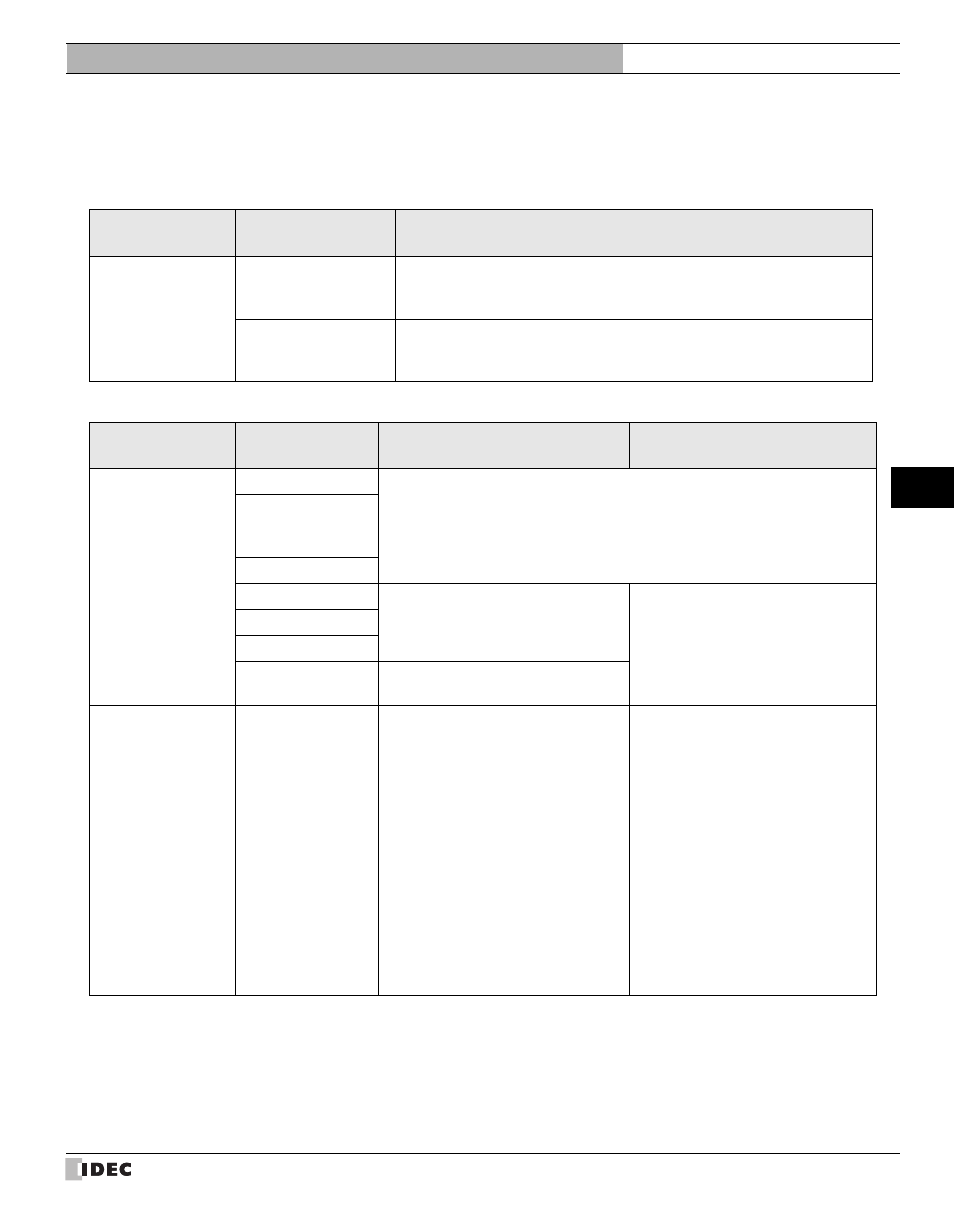

To use the O/I Link Communication, you must set the necessary items in the O/I Link tab of the Configuration - System Setup -

Project dialog box. (Refer to the WindO/I-NV2 User’s Manual or SmartAXIS Touch User's Manual.)

In addition, make the following settings for the PLC Link Communication.

Dialog Box Name

- Tab Name

Setting

Description

Project Settings -

O/I Link

O/I Link Station

Set the MICRO/I or Touch connected to the PLC as the master, and the other

MICRO/I or Touch as slaves (1 to 15). Make sure that the settings do not over-

lap.

Slave Station

MICRO/I or Touch that are connected to the master MICRO/I or Touch (i.e.

the one whose O/I Link Type is registered as Master) must be registered as

slaves (1 to 15). Select the checkbox.

Dialog Box Name

- Tab Name

Setting

Master

Slave 1 to 15

Project Settings -

Host I/F Driver or

Communication

Driver

Manufacturer

Use the same setting for all MICRO/I or Touch.

Host I/F Driver,

Communication

Driver

Connection Type

Transmission Wait

Set it according to the environment.

Setting not required.

Time Out

Retry Cycles

Other

Match to the setting of the PLC that you

will use.

Project Settings -

Communication

Interface

SERIAL 1/COM1

The use of Serial 1 depends on the fol-

lowing selected O/I type :.

HG2G-5F, HG3G/4G series:

Select “O/I Link Slave” as the interface

used for O/I Link communication.

Serial 1 maybe selected as the “O/I

Link Master” for O/I Link communi-

cation, or select “Host Communica-

tion” as the communication interface

for PLC communication.

HG2G-S/-5S, HG1F/2F/3F/4F series:

Select “Host Communication”.

Touch:

Select the External Device Com-

munication.