Cub Cadet 4 x 4 Volunteer User Manual

Page 95

Chapter 3 - Drive System: Drive Shafts and Differentials

91

4.

Manually rotate one rear wheel, with the differ-

ential lock disengaged:

•

If the vehicle is in neutral, the drive shaft leading

from the transfer case to the differential will turn.

•

If the transfer case is in gear, the other rear

wheel should rotate in the opposite direction.

5.

Engage the differential lock and rotate one rear

wheel:

•

If the vehicle is in neutral, both rear wheels will

rotate in the same direction and the drive shaft

leading from the transfer case to the differential

will turn.

•

If the transfer case is in gear, the wheel will be

extremely difficult to turn. The opposite rear

wheel will turn in the same direction, the drive-

shaft will turn, and the driven element of the CVT

will turn.

NOTE: It may take a few degrees of rotation

before the differential lock engages. It will emit

and audible “click” when it does.

6.

If the differential lock fails to engage or disen-

gage as it should, the problem may be internal,

or the problem may be in the linkage. Before

removing the differential, confirm that the prob-

lem does not lie in the linkage.

7.

Confirm that the linkage moves freely through its

range of travel.

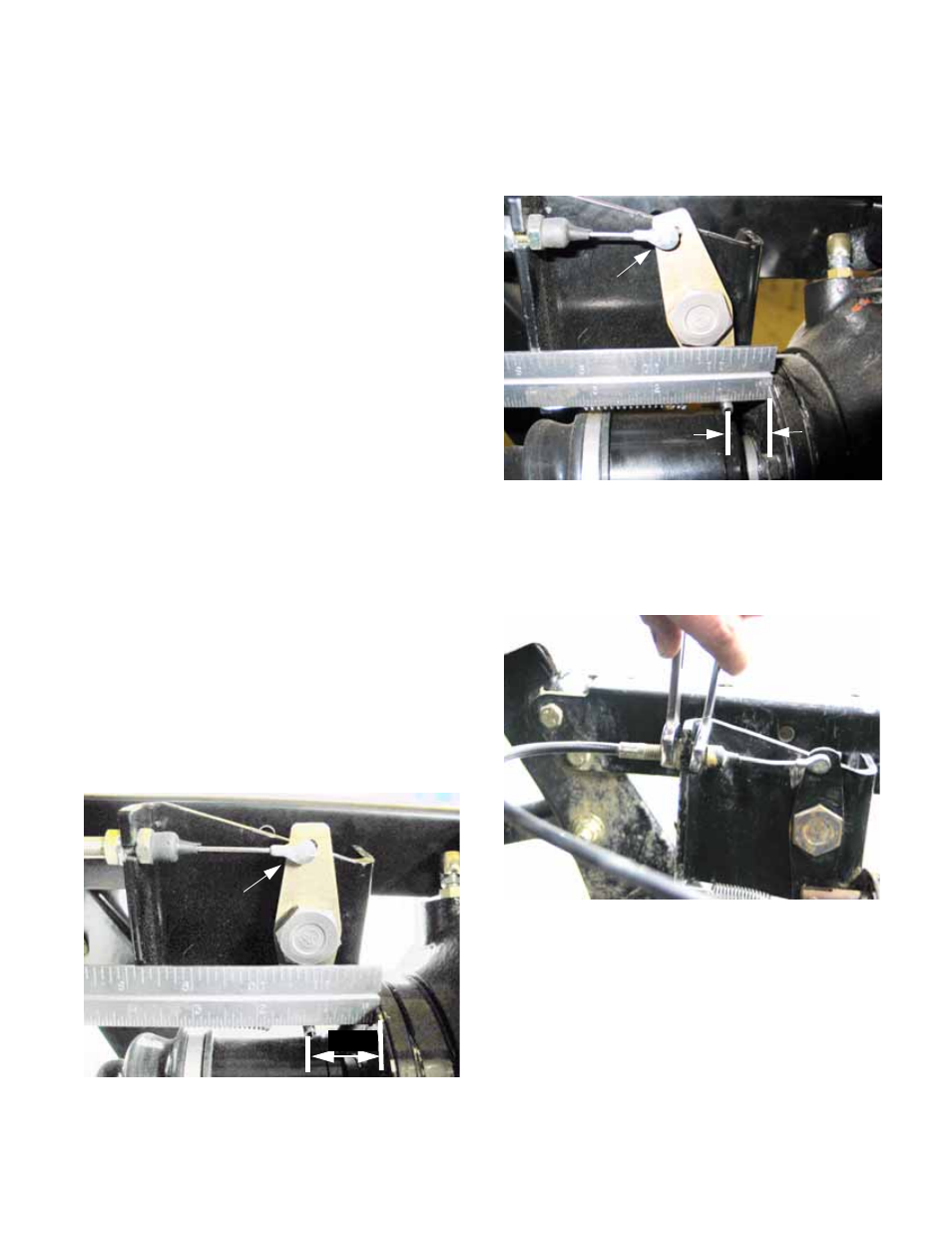

When released, the center line of the pin that

connects the shift fork to the linkage should be

1-1/8” (32mm) from the end housing that sup-

ports the sealed carrier bearing.

See Figure 3.5.

Figure 3.5

1.125”

Released

8.

When the differential lock is engaged, there

should be about 3/4” (19mm) from the centerline

of the pin to the end housing that supports the

sealed carrier bearing. See Figure 3.6.

9.

To accommodate this roughly 3/8” (9.5mm) of

travel, the cable should be adjusted so that it is

just slack in the disengaged position.

See Figure 3.7.

NOTE: There will be about 1/2” of free-play as

measured at the top of the control lever.

9.1.

Loosen the jam nut and adjust the cable at the

differential bracket using a pair of 1/2” wrenches.

9.2.

Tighten the jam nut and test the operation of the

differential lock when adjustment is complete.

Figure 3.6

.75”

Engaged

Figure 3.7

Adjustment point