Chapter 2- drive system: cvt and transfer case – Cub Cadet 4 x 4 Volunteer User Manual

Page 56

Chapter 2- Drive System: CVT and Transfer Case

52

3.

Assemble the three main shafts:

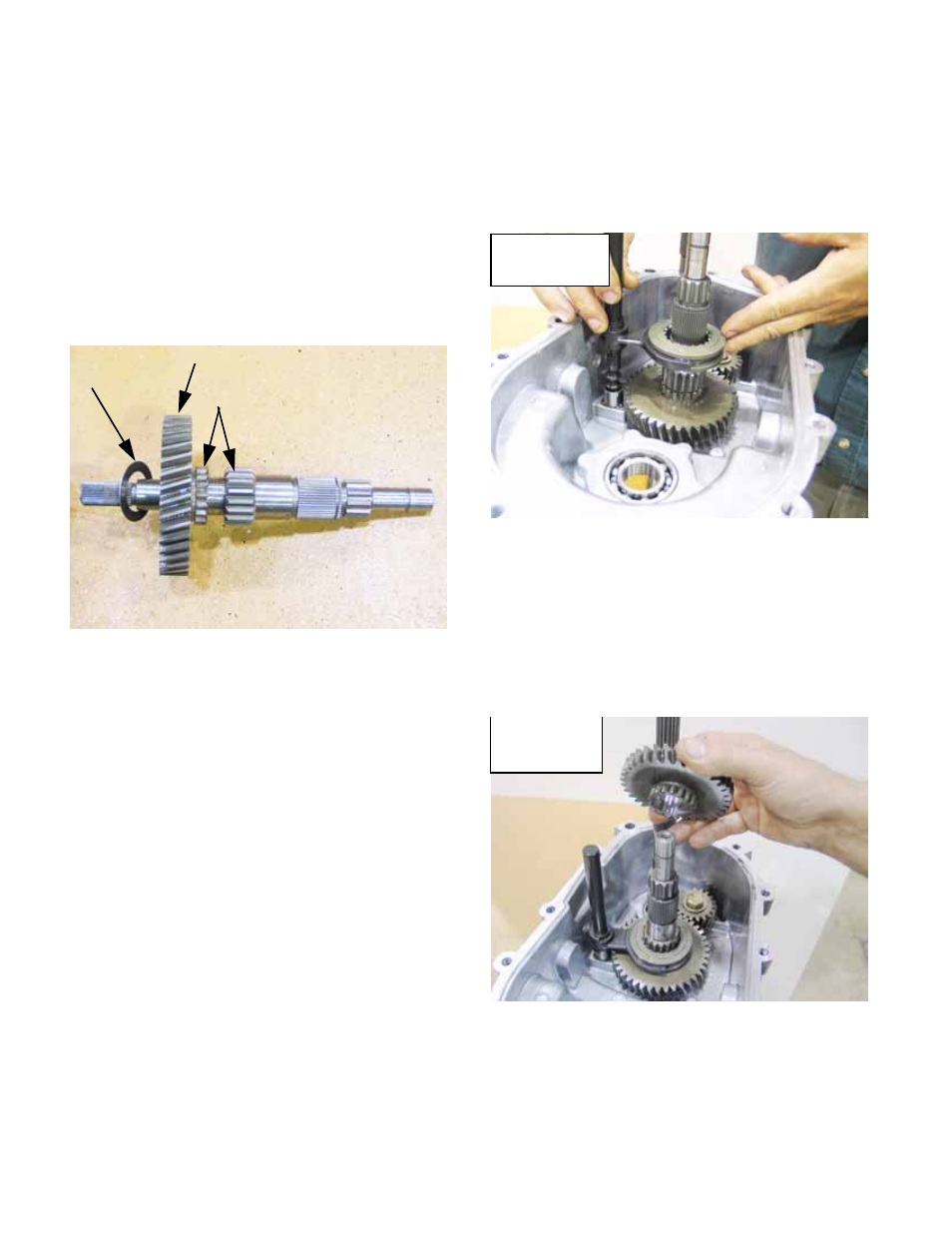

3a. Position the input shaft /reverse gear in

the right side case half, meshing with the

reverse idler.

3b. Apply a small amount of grease such as

Cub Cadet multi-purpose grease (P/N

737-3034) to the bearing inside the

reverse gear and position the gear on the

middle shaft so that the dog teeth on the

gear are next to the dog teeth on the

shaft. See Figure 2.123.

3c. Install the .030” (.76mm) flat washer on the

middle shaft, behind the reverse pinion.

3d. Insert the splined end of the middle shaft,

with the gear and washer on it, into the

middle bearing in the right side case half.

3e. Apply a small amount of anti-seize com-

pound to the inside diameter of the for-

ward-neutral-reverse shift collar.

3f. Position the shift collar and travel-stop

spacer on the forward-neutral-reverse

shift shaft assembly.

NOTE: The forward-neutral-reverse shift shaft is

the one with the shift yoke near the middle. The

spacer goes between the yoke and the detent

notches in the shaft.

3g. Apply a small amount of grease such as

Cub Cadet multi-purpose grease (P/N

737-3034) to the shift shaft, and insert the

D-shaped end of the shaft in the small

bore that is farther from the input shaft.

See Figure 2.124.

NOTE: The shift collar should seat over the

teeth on the shaft and reverse pinion.

3h. Apply a small amount of anti-seize com-

pound to the inside diameter of the for-

ward (high) gear, and install it on the

middle shaft, with the dog teeth facing the

shift collar. See Figure 2.125.

Figure 2.123

Reverse gear

Washer

Dog teeth

Middle shaft

Figure 2.124

Installing the

F-N-R shift shaft

and shift collar

Figure 2.125

Installing the

high-range

(forward) gear