Cub Cadet 4 x 4 Volunteer User Manual

Page 113

Chapter 3 - Drive System: Drive Shafts and Differentials

109

3.

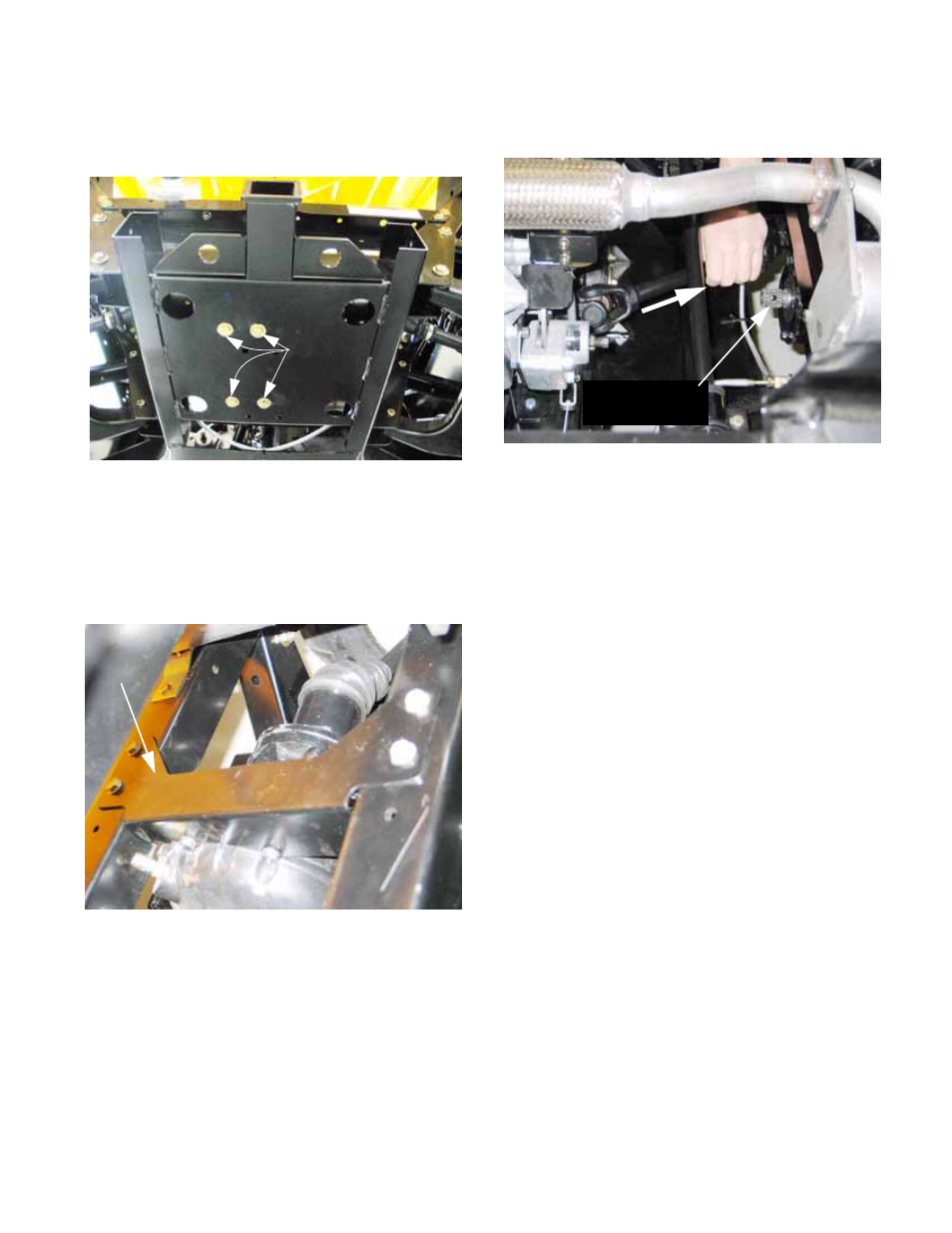

Remove the four bolts that hold the bottom of the

rear differential to the frame using a 9/16”

wrench. See Figure 3.53.

3.1.

Remove two bolts that hold the differential hous-

ing to the torque bracket using a 13mm wrench.

3.2.

Remove the rear differential torque bracket from

the frame using a 1/2” wrench.

See Figure 3.54.

4.

Slide the differential back, allowing the driveshaft

to disconnect from one end.

Figure 3.53

Rear differential

mounting bolts

Accessible from beneath vehicle

Figure 3.54

Torque

bracket

5.

Once disconnected, remove the driveshaft.

See Figure 3.55.

6.

Assembly notes:

•

Inspect the splines and shaft seals before install-

ing the drive shaft. Make any needed repairs

before reassembly.

•

Apply anti-seize compound to the splined joints

on assembly.

•

Replace any worn components before reassem-

bly. If the self-locking feature of any of the nuts

is worn, replace the nuts or use thread locking

compound such as Loctite

R

242 (blue).

•

Apply permanent thread locking compound such

as Loctite

® 262 (red) to the bolts that fasten the

torque bracket to the differential housing.

•

Reverse the removal procedure to install the

rear drive shaft.

•

When locating the front differential, install all of

the hardware that secures the differential and

torque bracket, then go back and tighten it.

•

Check the level of the gear lube in the differen-

tial. Top-up if needed before running the vehicle.

•

Tighten the hardware to the torques specified in

the accompanying table:

Figure 3.55

Rear

drive shaft

Rear differential

pinion spline