Cub Cadet 4 x 4 Volunteer User Manual

Page 209

Chapter 7 - Kohler Engine Service Access and Fuel System

205

19.

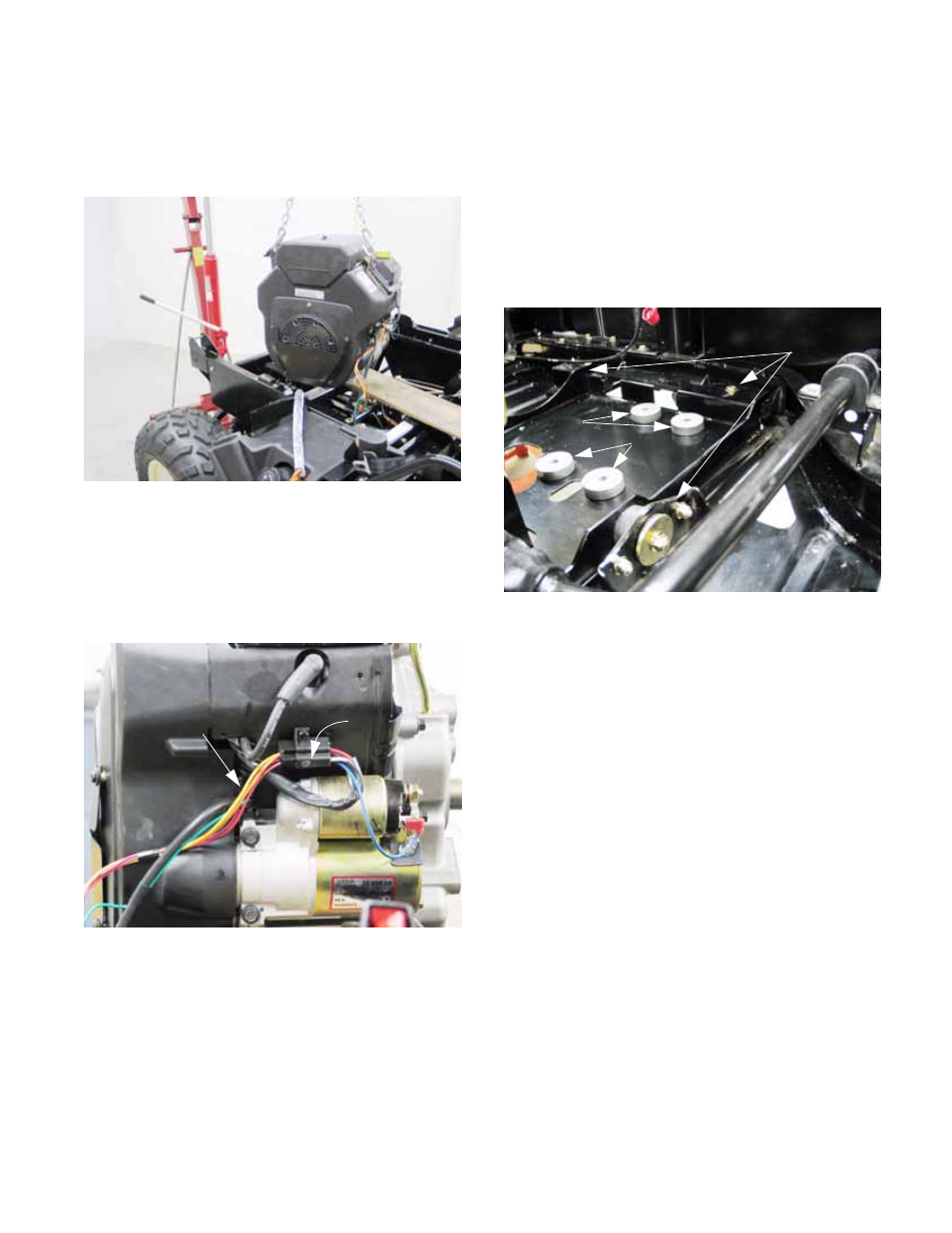

Attach a lifting apparatus, and carefully raise the

engine. Support the engine without straining

any of the electrical connections.

See Figure 7.32.

NOTE: Be careful of the engine oil drain valve.

It hangs-down slightly beneath the bottom of the

crankcase.

20.

Disconnect the remaining wires between the

engine and the vehicle. See Figure 7.33.

•

Unplug the engine harness from the main wiring

harness.

•

Disconnect the heavy gauge black ground cable

and its attached light gauge green ground wire

from their attachment point on the upper starter

bolt using a 10mm wrench.

Figure 7.32

Engine is

lifted and

supported for

final disconnection

of wires

Figure 7.33

Engine

harness

Vehicle harness

21.

Remove the engine completely, placing it on a

strong workbench or stable work platform.

22.

Prior to engine installation, check all the service

points on the engine that are easily assessable

while it is removed.

23.

Prior to engine installation, check all of the ser-

vice points on the chassis that are easily

reached while the engine is removed.

See Figure 7.34.

•

Check the rubber isolator mounts that connect

the drive system cradle to the frame. Replace

any that are suspect.

•

The metal spacers that the engine rests on can

be held in place during engine installation with

silicone RTV sealant or automotive trim adhe-

sive.

Figure 7.34

Engine tray

isolator mounts

Engine

mounting spacers