Cub Cadet 4 x 4 Volunteer User Manual

Page 303

Chapter 9 - Electrical

299

Wiring diagram or schematic

•

A wiring or a schematic diagram, and the ability

to read it are very important in troubleshooting a

circuit. The diagram shows how the circuit was

designed and what paths the electricity is sup-

pose to flow.

Fused jumper wires

•

Fused jumper wires are handy to help find bad

grounds or to jump across switches for testing

purposes.

CAUTION: Only use fused jumper wires. If there

is a short in the circuit, using an unfused jump

could damage components in the circuit.

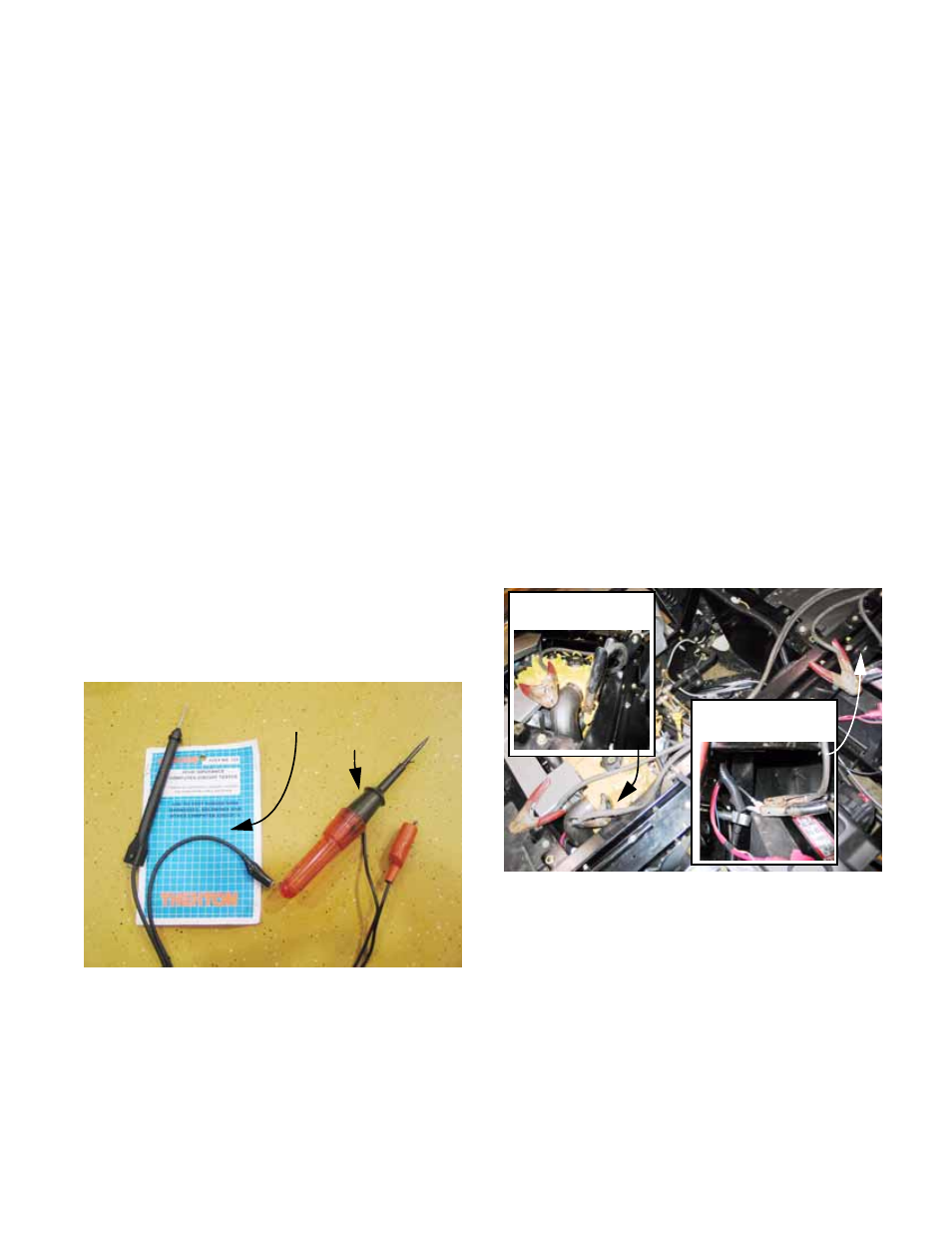

Test lights

•

Test lights are used as a quick way to verify volt-

age at a point in a circuit. Like DVOMs, they

come in a wide variety from many manufactur-

ers.

•

The most basic test lights simply use the current

being checked to light an incandescent lamp.

These should not be used on any equipment

that has or may have solid-state circuitry.

The power necessary to light the bulb is more

than many solid-state circuits were designed to

handle. Components will be destroyed in the

process of testing them. See Figure 9.51.

•

If a test light is used at all, it should have “high-

impedance”, indicating that it only takes a sam-

ple of the electricity being tested, and illuminates

an LED to indicate the presence of power.

Figure 9.51

Hi impedance test light: Incandescent

GOOD test light:

CAUTION

•

Some high impedance test lights are capable of

indicating whether the current being sampled is

AC or DC.

Self-powered continuity lights

•

Continuity lights can indicate whether a circuit is

complete or not, but they give no indication of

resistance. They are handy for finding point-

break when static-timing some older engines,

but have largely been replaced by DVOMs.

•

There are some powered high-impedance test

lights on the market that have a continuity fea-

ture, and some technicians like the fact that they

can be less bulky than a DVOM.

Battery Jumper Cables

•

The obvious use: jumper cables can be used to

jump-start equipment to get it into the shop. This

is not recommended for any fuel injected Kohler-

powered equipment.

•

The clever use: If the technician suspects that

there is resistance on the ground side of the sys-

tem, a quick-and-dirty test can be made using

jumper cables. See Figure 9.52.

•

Connect one cable clamp to the negative post of

the battery, and connect the clamp at the other

end of the same cable to the engine block.

•

If there is an immediate difference in starter

motor performance, use the voltage drop tech-

nique discussed later in this section to identify

the source of the resistance.

Figure 9.52

Inset:

Block connection

Inset:

Battery connection