Chapter 6 - hydraulic brakes – Cub Cadet 4 x 4 Volunteer User Manual

Page 184

Chapter 6 - Hydraulic Brakes

180

7.

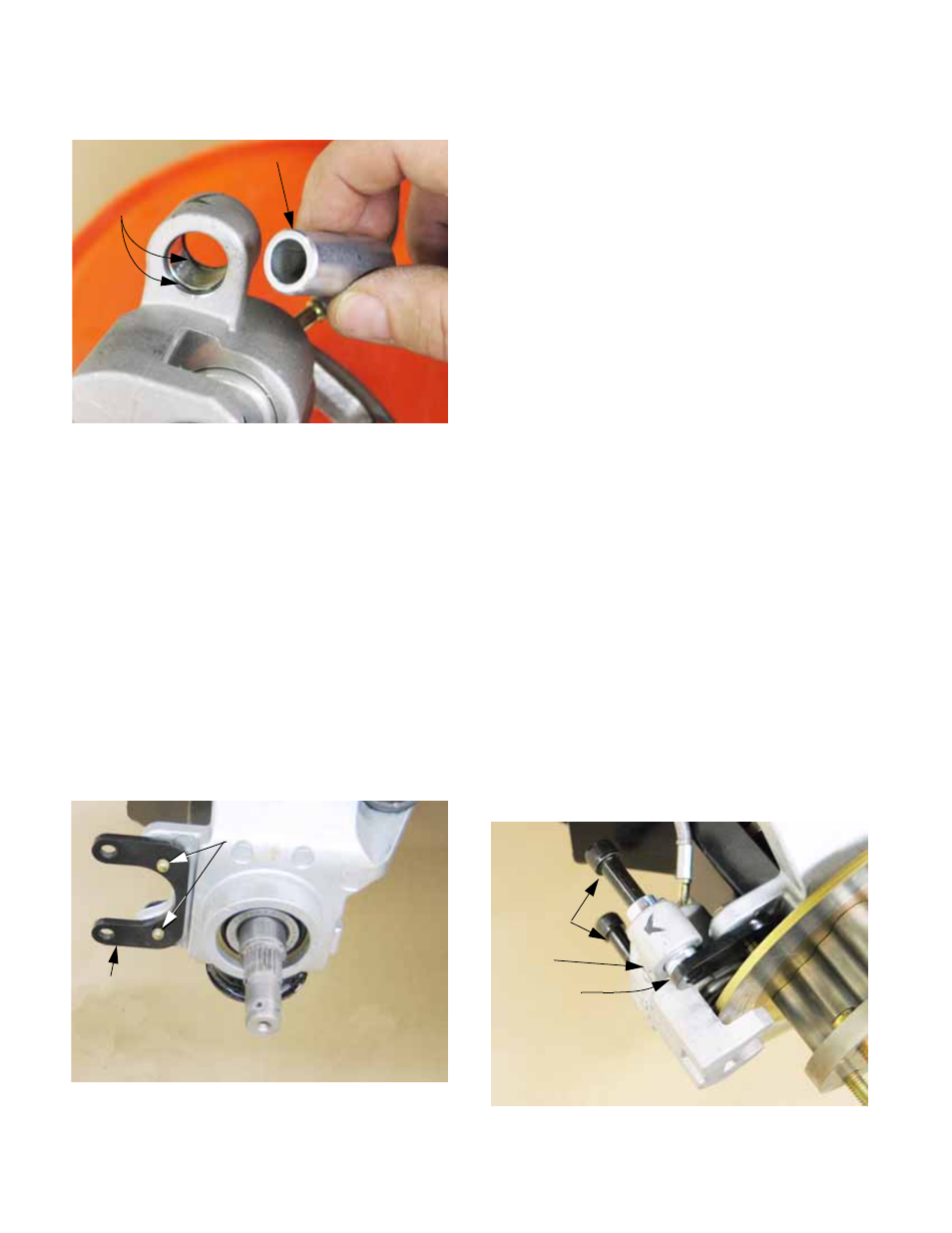

Check the slide bushings. See Figure 6.17.

•

The slide bushings should be clean, and free to

slide in the mounting bores of the caliper.

•

O-rings provide a seal between the bushings

and the caliper.

•

Uneven pad wear may indicate that the caliper is

not sliding as designed, and the slide bushings

require attention.

•

On assembly: lubricate the O.D. of slide bush-

ings or the I.D. of the bore with a high tempera-

ture synthetic grease that is meant for use on

brake calipers. Typical of these products is

Versachem Part Number 26111, available

through NAPA® as Item #BK7653072.

8.

Check the brake caliper bracket for damage or

loose hardware. See Figure 6.18.

9.

Check the brake rotor as described in the follow-

ing section of this manual before reinstalling the

caliper. Replace the rotor if necessary.

10.

Installation notes: brake caliper

See Figure 6.19.

NOTE: A brake pad service kit is available as

959-04116. This kit is not shown in the Illus-

trated Parts List. The kit consists of: two brake

pads, two slide pins, and two retaining rings.

This will service a single wheel. Two kits are

required for an axle. The same kit is used for

front and rear wheels

10a. If brake rotor has been removed, install

the brake rotor.

10b. Clean any grease, oil, or fingerprints from

the brake rotor.

10c. Apply a very small amount of anti-seize

compound to the shoulders of the caliper

mounting bolts (slide pins).

10d. Position the caliper on the caliper bracket,

and insert the slide pins just far enough to

hold the caliper in place.

10e. Slip the piston-side brake pad into place,

pushing the slide pins through far enough

to hold the piston-side pad.

10f. Slip the outside pad into place, and com-

plete the installation of the slide pins:

push them in until the threads engage,

then tighten them to the specified torque

using a 3/8” allen wrench.

10g. Install the C-clips that secure the brake

pads. If there is any question of the condi-

tion of the C-clip replace it with a new one.

Figure 6.17

Slide bushing

O-ring seals

Figure 6.18

Brake caliper

bracket (rotor

removed for

visibility)

If removed, apply

thread-locking sealant

such as Loctite

®

262 (red)

to threads, and tighten

to a torque of 22-26 ft-lbs

(30-35 N-m)

Figure 6.19

Slide pins

Caliper

Inside pad