Chapter 9 - electrical – Cub Cadet 4 x 4 Volunteer User Manual

Page 312

Chapter 9 - Electrical

308

4e. If the battery is being checked indepen-

dently of the equipment it powers, mea-

sure and note the battery voltage while it

is disconnected, over a three-day period.

4f. There should be less than a .2 volt drop in

the readings. If there is more than a .2 volt

drop, the battery is bad.

5.

Storage of batteries

5a. Always store a battery with a full charge

(unless the battery is a dry battery and the

electrolyte has not been added yet). This

may require periodic re-charging.

5b. Take measures to prevent the battery from

freezing in cold weather. The electrolyte

in a fully charged battery has a lower

freezing point than the electrolyte in a bat-

tery with a lower state of charge.

5c. Store the battery in a cool, dry place.

5d. If storing multiple batteries (primarily store

stock), rotate the stock so that the oldest

battery goes out first. This will increase

the life of the batteries.

6.

Troubleshooting

6a. The first step in troubleshooting is to

always verify the complaint. Defining and

verifying the problem reduces the possi-

bility of misunderstanding and helps clar-

ify the diagnostic approach.

6b. The next step is to check the simple stuff

first:

•

Check the fuse or fuses. Some models have

ground side fuse. Failure of any fuse is an indi-

cation that there is a problem of some sort in the

circuit that the fuse protects.

•

Look for obvious physical damage.

•

Use the hour meter and indicator lamps as a

guide to direct the search.

As an example, when diagnosing a “no-crank”

condition on a lawn tractor with a PTO safety

switch: if the PTO light is lit on the hour meter

but the technician has visually verified that the

PTO clutch is not engaged, the PTO circuit

would be a reasonable place to check for prob-

lems.

•

Check the battery. A valid diagnosis of many

systems cannot be made without full system

voltage applied.

6c. Take a methodical approach to finding the

problem.

As a rule of thumb, start at one end of the

circuit and work to the other.

6d. The next step is to decide what method to

use to troubleshoot the circuit.

•

If checking a safety circuit that grounds the mag-

neto, use Ohms to test for continuity.

•

If checking a safety circuit that enables a starter

motor or accessory, us a volt meter to confirm

the presence of power at each junction in the

system.

•

If a circuit does not work at all, look for a short or

an open.

•

If the circuit works slowly or intermittently, look

for resistance by doing a voltage drop test.

NOTE: In all diagnosis, it is very important to

understand the circuit that is being checked.

The use of a schemantic is recommended, even

if a technician is thoroughly familiar with the sys-

tem.

7.

Testing for opens/shorts

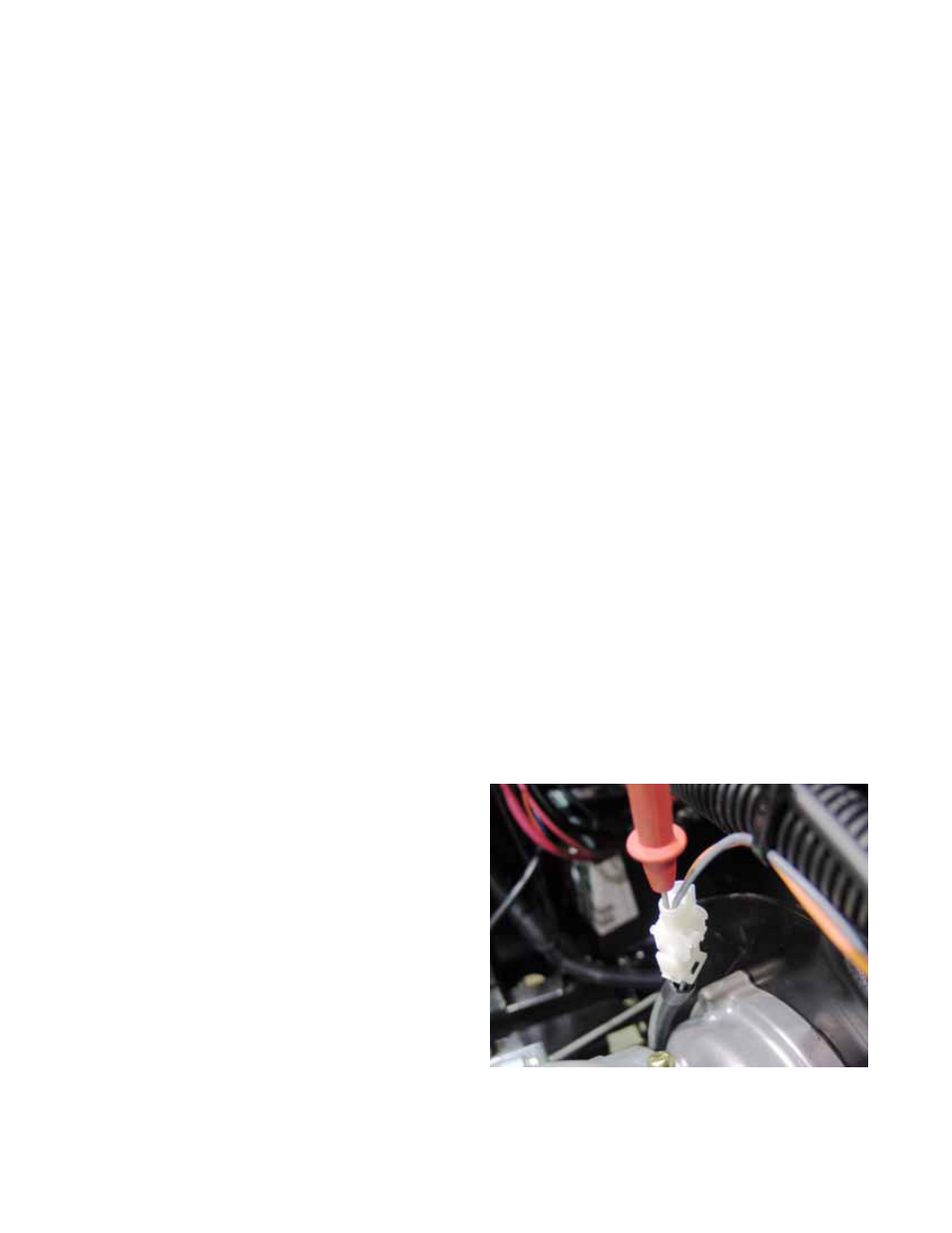

NOTE: When checking circuits for continuity,

disconnect the circuit at the nearest plugs and

use the metal terminals of the plug as a connec-

tion point for the test probes. DO NOT STAB

THE WIRES.

NOTE: When checking circuits for voltage,

back-probe the terminals nearest the point to be

checked. DO NOT STAB THE WIRES.

See Figure 9.68.

Figure 9.68