Chapter 2- drive system: cvt and transfer case – Cub Cadet 4 x 4 Volunteer User Manual

Page 51

Chapter 2- Drive System: CVT and Transfer Case

47

3.

Check the forward / reverse shift yoke (fork) and

shift collar groove for wear:

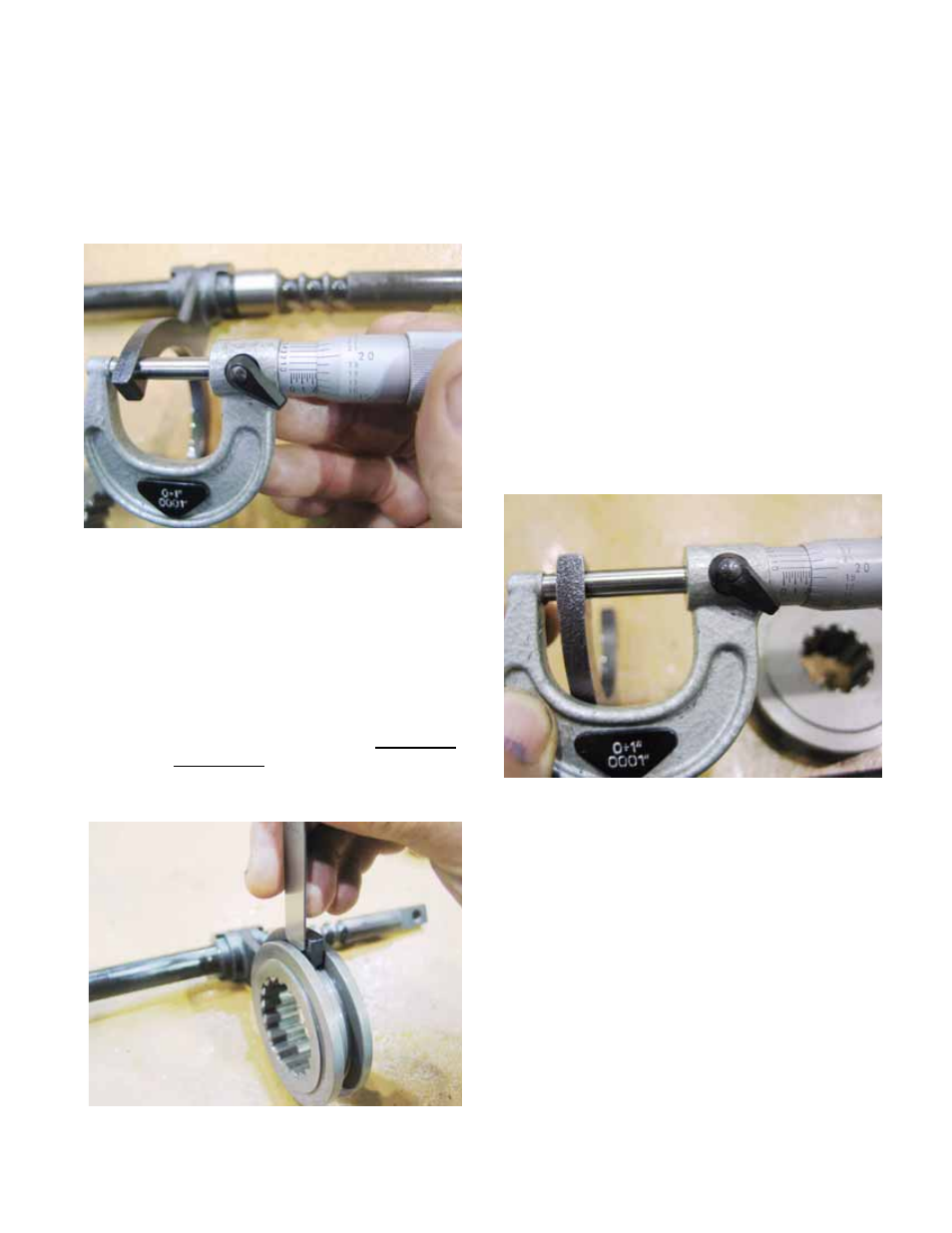

3a. Check the thickness of the shift yoke pad

that contacts the shift collar using a

micrometer (preferably) or calipers.

See Figure 2.110.

•

The minimum pad thickness on the shift yoke

that moves the forward / reverse shift collar

should be .230” (5.842mm). If it is worn further

there is some chance that the case hardening

will soon be worn through.

3b. Check the forward / reverse shift collar

groove for wear: Use a .035” (.889mm)

feeler-gauge as a go / no-go tool. If the

feeler gauge can be inserted to the base

of the groove in the shift collar, and the

shift yoke is good, replace the shift collar.

See Figure 2.111.

Figure 2.110

Checking F-N-R

shift yoke

Figure 2.111

Checking F-N-R

shift collar

3c. Inspect the shift shaft for wear on the mat-

ing and seal surfaces.

3d. Check that the snap rings are seated in

their grooves. If removed, replace the

snap rings with new ones.

NOTE: if the shift yoke and collar show wear

from a constant thrust load on the shift shaft

(wear, scoring, or discoloration) the cause of the

damage must be corrected. It may be a operator

abuse by applying force to the Hurst gear selec-

tor while the vehicle is in motion, or it may be an

issue with the linkage.

4.

Check the low gear shift yoke (fork) and shift col-

lar groove for wear:

4a. Check the thickness of the shift yoke pad

that contacts the shift collar using a

micrometer (preferably) or calipers.

See Figure 2.112.

•

The minimum pad thickness on the shift yoke

that moves the forward / reverse shift collar

should be .2225” (5.715mm). If it is worn further

there is some chance that the case hardening

will soon be worn through.

Figure 2.112

Checking low-range shift yoke