Drive system adjustments, Cvt service, Chapter 2- drive system: cvt and transfer case – Cub Cadet 4 x 4 Volunteer User Manual

Page 17

Chapter 2- Drive System: CVT and Transfer Case

13

DRIVE SYSTEM ADJUSTMENTS:

1.

CVT spacing and alignment:

•

Spacing and alignment are critical to proper CVT

performance and belt longevity.

•

In normal service, these items should not be an

issue on this vehicle. The engine and transfer

case are firmly tied to each-other by the engine /

transmission plate that holds proper spacing and

alignment.

2.

Adjustment of the driving element and driven

element:

•

The CVT is tuned to maximize performance of

the vehicle. It should require no adjustment in its

normal service life.

•

While it is mechanically possible to disassemble

the driving and driven elements, individual parts

will not be available through Cub Cadet.

CVT SERVICE

1.

BELT REMOVAL

NOTE: The procedure to remove the belt is the

same for the Kohler and the Caterpillar engines.

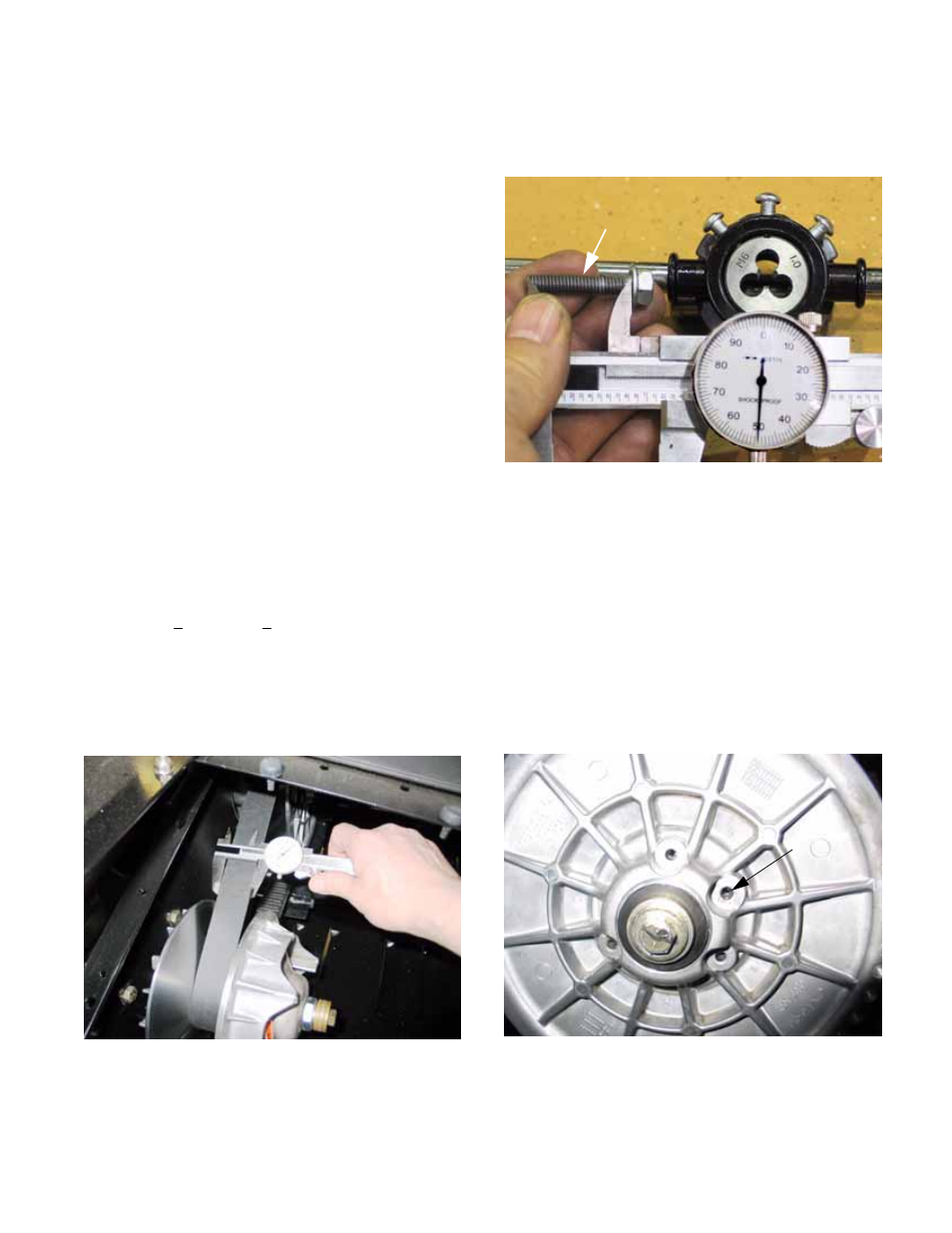

1a. When new, the belt measures 1.335”

+.031” (33.9 + .8mm) across the wide flat

outside surface of the belt. The belt is

considered worn when the measurement

is 1.20” (30.5mm) or less. some degrada-

tion of performance may begin to occur as

belt is worn to less than 1.275” (32.4mm).

See Figure 2.9.

Figure 2.9

New: 1.335”

(33.9mm)

Worn: 1.20”

(30.5mm)

1b. To remove the belt, a 6mm/1.0 screw with a

minimum thread length of 1.15" (2.9cm)

will be required. See Figure 2.10.

NOTE: A 6mm screw with a thread pitch of 1.0

may be purchased locally. The minimum thread

length needed is longer than the threads of a

standard screw of this size. It will be necessary

to cut threads further up the shank of the screw

using a thread-cutting die.

1c. There are 4 holes in the face of the driven

element. Three of them are close

together, one is 180 degrees away from

the others. The middle hole of the set of

three is threaded.

See Figure 2.11.

Figure 2.10

1.15” (2.9cm)

thread length

Figure 2.11

Tapped hole