Cub Cadet 4 x 4 Volunteer User Manual

Page 106

Chapter 3 - Drive System: Drive Shafts and Differentials

102

4b. Move the hub and lower control arm out

and forward far enough to slip the end of

the axle out of the hub. See Figure 3.37.

NOTE: Use caution not to strain the brake line.

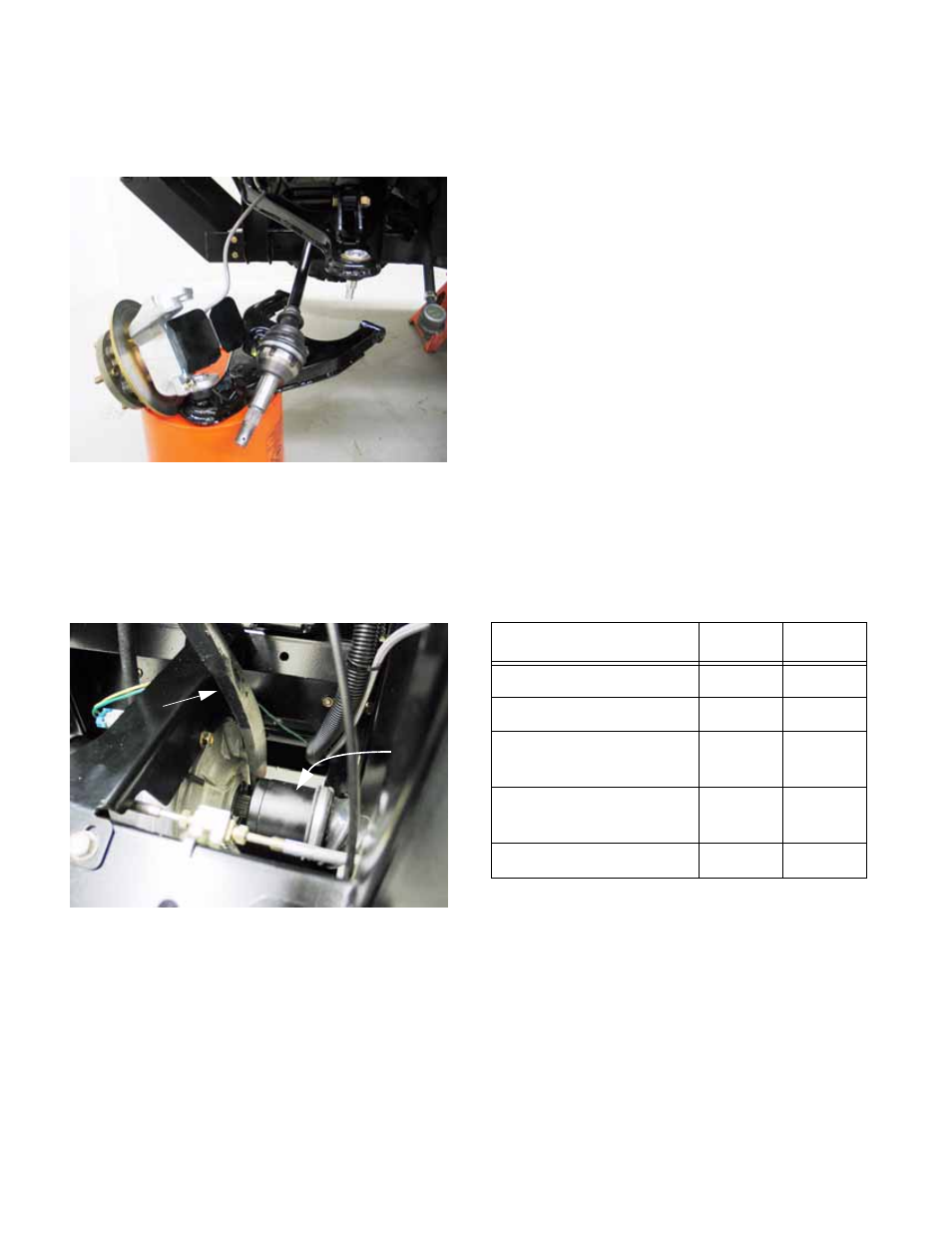

5.

The inner constant velocity joint is held into the

differential by a hog ring. Use a pry bar to pop

the joint loose from the differential.

See Figure 3.38.

CAUTION: When working on the left side of the

vehicle, be very careful not to damage the wires

that control the front differential engagement.

6.

From this point, any repairs to the drive shaft can

be made on the bench, or the shaft can be

replaced as a complete unit.

7.

Installation notes:

•

Apply anti-seize compound to the splines of the

axle before assembly.

•

Apply anti-seize compound to the bolts that hold

the lower control arm to the frame.

•

Replace any worn hardware or components

before reassembly. If the self-locking feature of

any of the nuts is degraded, replace the nuts or

apply thread locking compound such as Loctite®

242 (blue) to the threads.

•

If the locking features of nuts on the tie rod end

or ball joint stud has worn, replace the nut. Do

not use thread locking compound.

•

Assemble the front suspension by reversing the

steps of disassembly.

NOTE: Tightening the nuts and bolts that hold

the control arm to the frame locks the control

arm bushings. Lower the vehicle to the ground

so that the suspension is loaded before tighten-

ing the nuts fully. This will prevent pre-loading of

the bushings.

•

Tighten fasteners to the torques specified in the

table.

8.

Test run the vehicle in a safe area before return-

ing it to service.

Figure 3.37

Figure 3.38

Pry bar

Inner

constant

velocity

joint

Item

ft-lbs

N-m

Tie rod end

22-28

3-38

Upper ball joint

22-28

3-38

Lower control arm to

frame

32-36

43-49

Axle nut

150-

165

203-

223

Lug nuts

65-75

88-102