Chapter 2- drive system: cvt and transfer case – Cub Cadet 4 x 4 Volunteer User Manual

Page 23

Chapter 2- Drive System: CVT and Transfer Case

19

NOTE: Methodology: start at the source (the

transfer case), and work toward the control input

(the gear selector).

5.

Operate the gear selector through its full range

of motion (high range forward, low range for-

ward, neutral, and reverse). Look for the follow-

ing issues: See Figure 2.26.

•

Lost motion

•

Loose hardware

•

Mechanical interference

•

Unintended bends in the linkage

•

Excessive linkage bowing under load

•

Engagement of the gear that is selected

6.

Correct any of these initial problems before pro-

ceding with adjustment.

NOTE: It is possible to make a damaged linkage

work better by compensating for the damage

with adjustment. This should not be considered

complete repair.

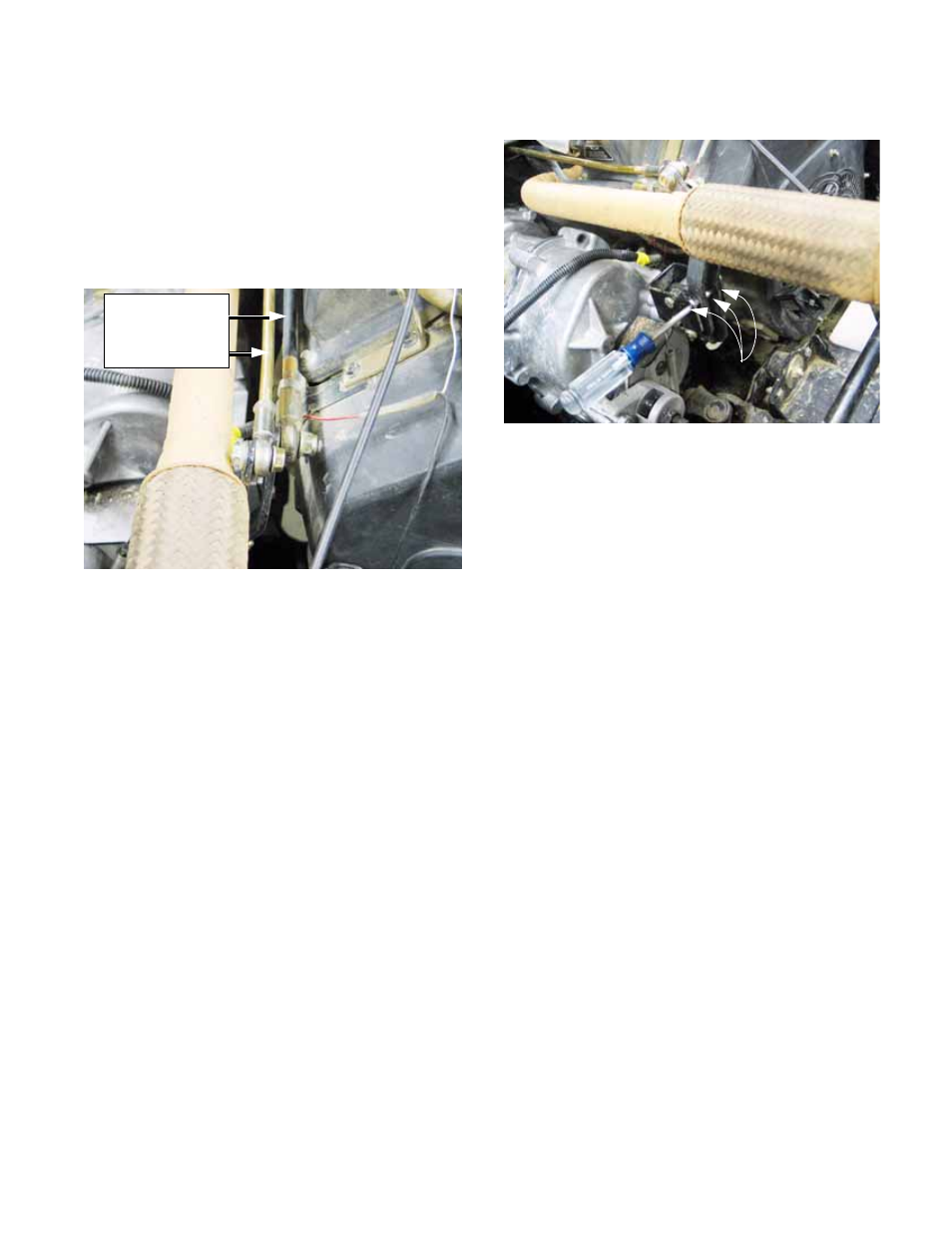

Figure 2.26

Forward-Neutral-

Reverse rod

Low-range rod

7.

Centering the linkage: See Figure 2.27.

7a. With the linkage disconnected, the shift

forks are centered in the neutral position

by detent springs.

7b. At this point the shift arms can be locked

into the neutral position by inserting a 3/

16” (or 5mm) dowel rod through the align-

ment holes in the shift lever bracket and

shift arms located on the back of the

transfer case housing.

7c. The center-point of neutral position at the

Hurst gear selector lever corresponds

with the center of the range where the

shift lever can move from the high-neutral-

reverse gait into the neutral-low gait.

7d. Find the point were the Hurst lever moves

left and right between the two gates. This

is the center-point of it’s range of travel.

Figure 2.27

Neutral

alignment

holes