Chapter 4 - front suspension and steering – Cub Cadet 4 x 4 Volunteer User Manual

Page 132

Chapter 4 - Front Suspension and steering

128

2.

Grasp the tire as described in the FRONT SUS-

PENSION INSPECTION: WHEEL BEARINGS

portion of this section of the manual.

3.

Apply a lifting/tilting force of 50-75 lbs. (22.7-

34kg.)

4.

If the wheel rocks more than 1/8” (.32cm)

beyond the wheel bearing play, one or both ball

joints are worn.

5.

To determine which ball joint is worn, it may be

necessary to have an assistant watch the move-

ment of the ball joints while force is applied to

them.

5a. If the brake rotor moves relative to the hub

carrier, the problem lies in the wheel bear-

ing.

5b. If the hub carrier moves relative to the

upper control arm, the upper ball joint is

worn.

5c. If the hub carrier moves relative to the

lower control arm, the lower ball joint is

worn.

Control arm busings

Each control arm is connected to the frame through

two control arm bushings that allow the arms to swing

up and down to accommodate suspension travel.

NOTE: The upper control arm bushings are

more prone to wear than the lower control arm

busings, but the technique for checking them is

the same.

Symptoms of a bad control arm bushing:

Worn control arm bushings will produce a heavy clunk

as the vehicle goes over bumps.

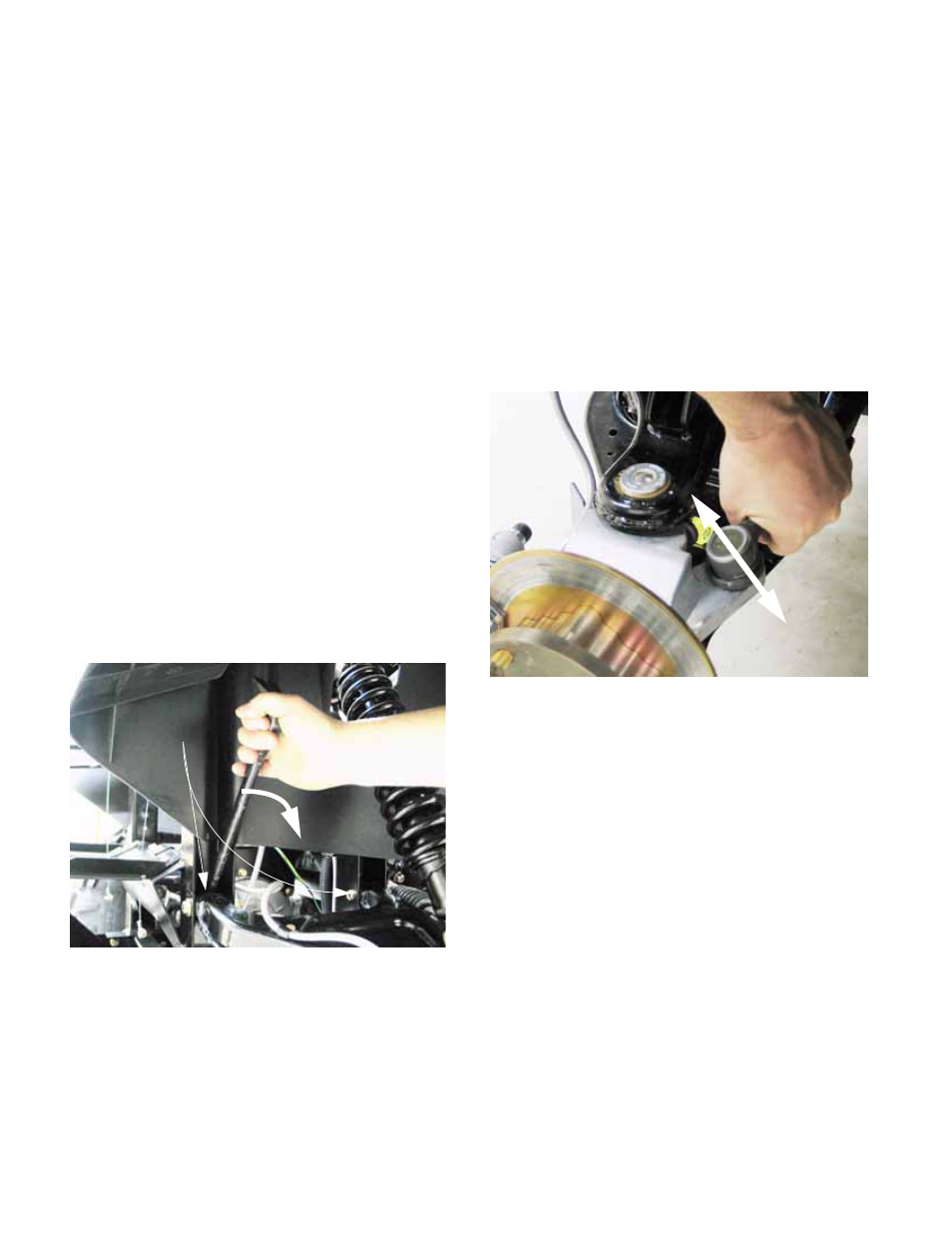

To check the control arm bushings: See Figure 4.10.

1.

With the weight of the vehicle resting on the sus-

pension, pry outward on the control arm, from

the point where it mounts to the frame.

2.

Repeat for each control arm bushing: upper.

lower, front, rear.

3.

If the control arm moves easily, the control arm

busings are worn.

Tie rod ends

Tie rod ends are spherical joints that connect the tie

rods from the steering gear to the steering arm on each

hub carrier. See Figure 4.11.

1.

Lift and safely support the front of the vehicle as

described in the INTRODUCTION section of this

manual.

2.

Remove the front wheel using a 3/4” wrench.

3.

Make a visual inspection of the tie rod end. If the

boot is broken, the tie rod end should be

replaced.

4.

Grip the joint firmly, and apply up/down force to

it.

5.

If significant play (1/16” or .16cm) is felt, the

joint should be replaced.

Symptoms of a bad tie rod end:

As a tie rod end goes bad, the vehicle may develop a

clunking noise when it goes over bumps, or a shimmy

at high speeds that is noticeable through the steering

wheel, particularly after hitting a bump.

A worn tie rod end may also clunk under braking, or

under acceleration when four-wheel-drive is engaged.

Figure 4.10

Upper control

arm bushings

Figure 4.11