Brake fluid flushing and bleeding, Chapter 6 - hydraulic brakes – Cub Cadet 4 x 4 Volunteer User Manual

Page 179

Chapter 6 - Hydraulic Brakes

175

BRAKE FLUID FLUSHING AND BLEEDING

The brake fluid should be flushed and bled every two

years.

The brake fluid should be bled any time the pressur-

ized portion of the hydraulic system has been opened.

If only one side of the system has been opened (front

or rear) then only that side needs to be bled. In general

practice though, it is usually convenient to bleed the

entire system

To bleed the brakes:

1.

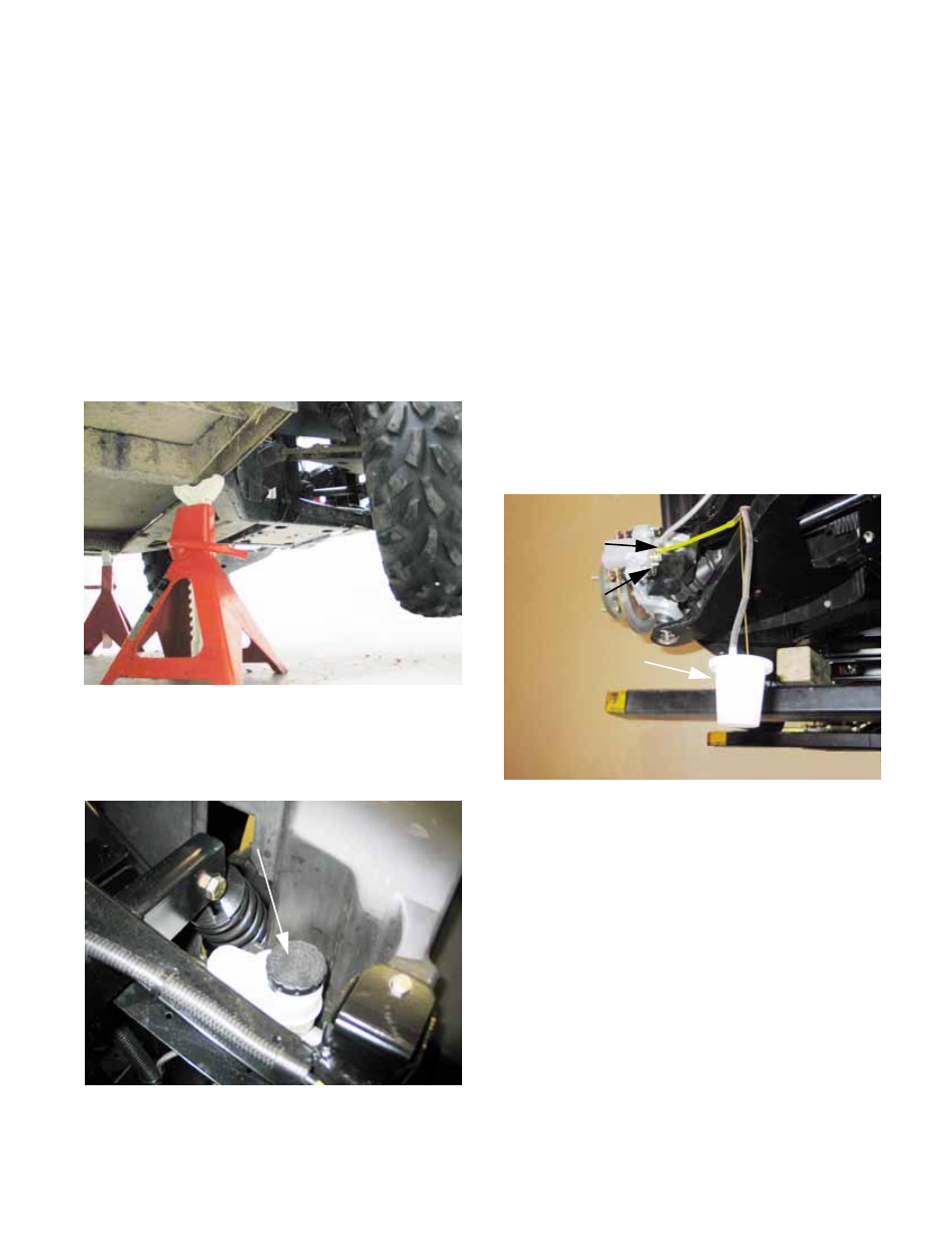

Lift and safely support the vehicle as described

in the Introduction chapter of this manual.

See Figure 6.6.

2.

Tilt the hood forward to reach the master cylin-

der. The hood may be removed, at the techni-

cian’s discretion. See Figure 6.7.

Figure 6.6

Figure 6.7

Keep master cylinder

reservoir filled to ”Full”

3.

Clean around the cap, and confirm that there is

sufficient fluid in the reservoir. Top-up if neces-

sary.

NOTE: Be careful of spilling brake fluid on

painted surfaces. While the powder-coat pro-

cess used on the frame of the Cub Cadet utility

vehicle line is relatively resilient to brake fluid,

surrounding surfaces may not be.

CAUTION: If the brake fluid level is low, identify

and repair the leak before operating the vehicle.

4.

Remove the wheels using a 3/4” wrench.

NOTE: Because the front and rear circuits are

independent, they can be bled independently. It

is most effective to start at the longer side of

each circuit: the passenger side.

5.

Connect a clear hose and catch bottle to the first

caliper that is to be bled. See Figure 6.8.

•

There are two bleeder screws on each caliper:

one near the top, and one near the bottom.

•

Bleeding to purge air is best done at the top fit-

ting.

•

When doing a periodic maintenance flush, a

small amount of fluid may be flushed from the

bottom fitting to remove any settled residue or

moisture.

6.

Open the bleeder screw using a 1/4” wrench.

NOTE: It may be necessary to loosen, rotate,

and re-tighten the banjo fitting slightly for wrench

clearance. Use a 1/2” wrench on the banjo bolt.

•

The system should gravity-bleed without any

additional pressure.

Figure 6.8

Upper

bleed screw

Lower

bleed screw

Fluid catch-bottle