Cub Cadet 4 x 4 Volunteer User Manual

Page 75

Kohler Enclosed CVT Addendum

71

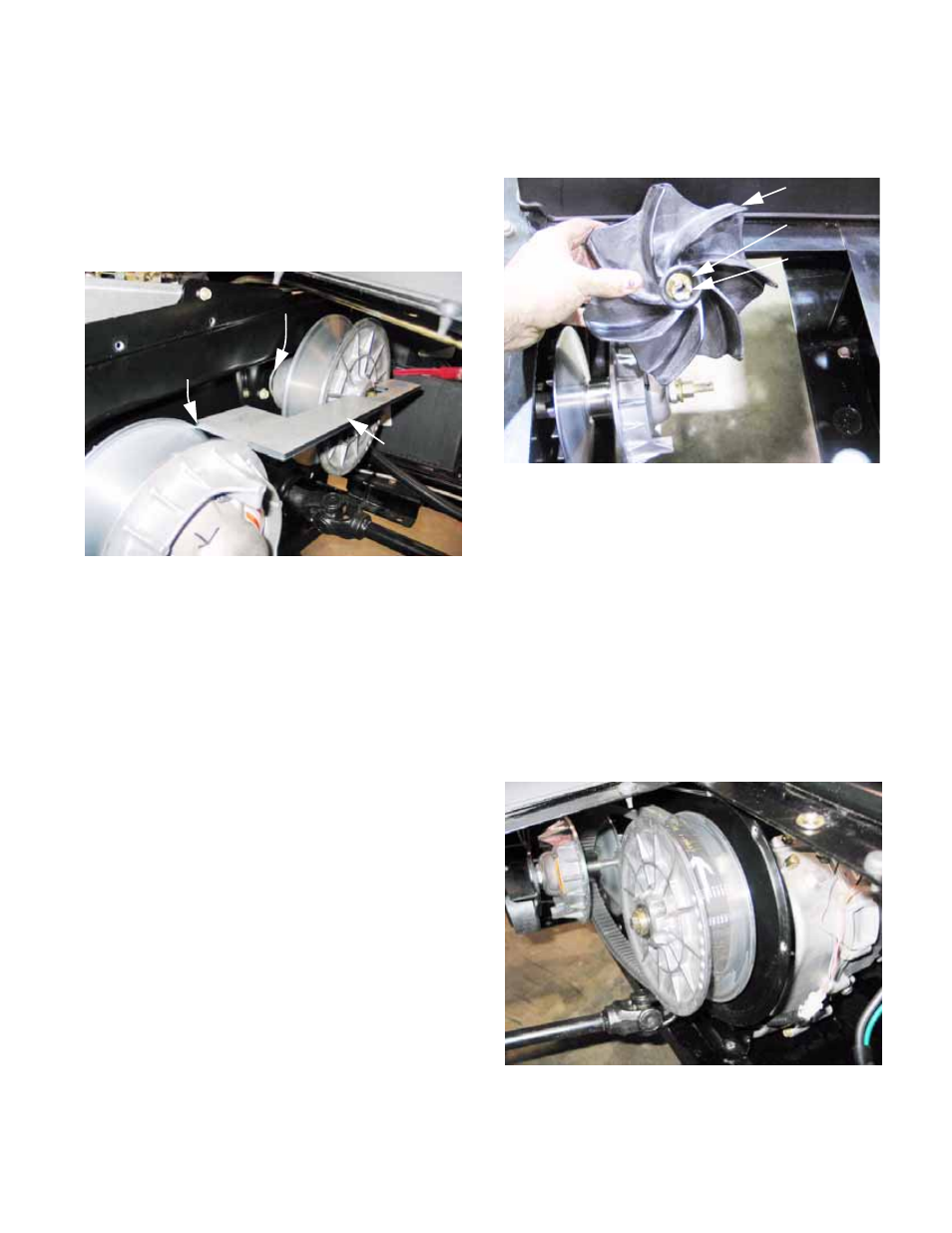

6d. Check the alignment of the two pulleys:

Place the alignment tool over the hub of

the driven pulley so that it lays flat against

the front surface of it.

The furthest corner of the thick end of the

tool should meet-up with the inner lip of

the fixed sheave on the driving pulley

See Figure 2a.25.

NOTE: The outer sheave of the driving pulley

moves inward to clamp the belt as engine RPMs

increase.

6e. Adjust the number of shims behind the

driven pulley to achieve correct alignment.

Use the three .800” (2 cm) I.D. flat wash-

ers that are included in the kit, if neces-

sary.

6f. Once alignment is correct, install the

driven pulley screw with thread locking

compound such as Loctite®

262 (red),

and tighten it to 32-36 ft-lb. (43-49 N-m).

Figure 2a.25

Critical

corner

Alignment

tool

Shims behind

driven pulley

6g. Install the cooling fan on the driving pulley,

securing it with the flat washer and castle

nut. See Figure 2a.26.

6h. Tighten the nut to a torque of 22-25 ft-lbs.

(30-34 N-m), then secure it using the cot-

ter pin.

6i. Inspect the drive belt. If it is worn to less

than 1.20” (30.5mm) across the flat back

surface of the belt, or if is shows signs of

burning or checking, replace it with a new

belt.

6j. Roll the drive belt back onto the pulleys.

Refer to the marks made before the belt

was removed, to confirm that the direction

of rotation has not been changed.

See Figure 2a.27.

Figure 2a.26

Fan

Washer

Castle nut

Figure 2a.27