Rear half shaft removal – Cub Cadet 4 x 4 Volunteer User Manual

Page 114

Chapter 3 - Drive System: Drive Shafts and Differentials

110

6.1.

Test-run the vehicle in a safe area before return-

ing it to service.

** Install with permanent thread locking compound

such as Loctite®

262 (red).

* Install with releasable thread locking compound

such as Loctite®

242 (blue).

REAR HALF SHAFT REMOVAL

1.

Failure mode, cause, and remedy:

•

The Rzeppa type constant velocity joints at each

end of the front half shafts are protected by rub-

ber boots. If a boot gets torn, the joint will be

damaged quite rapidly by any foreign material

that gets into the joint. Replace the joint if a boot

is compromised for any significant length of time.

•

Heat is the enemy of rotating joints. These joints

should be kept clean to dissipate heat. Avoid

pressure washing. Wipe the joints clean when

they become dirty.

•

If a joint begins to click, that is a sign that the

internal races have troughs worn into them. The

clicking is the sound of the balls that transmit

force between the inner and outer races passing

over the trough. A Rzeppa joint that clicks as

the steering or suspension travel through their

range of motion has worn, and should be

replaced.

•

At the time of printing, it is uncertain if replace-

ment axle components will be available:

- Replacement boots may be available for instal-

lation on the constant velocity joints

- Replacement joints may be available for instal-

lation on the axles.

- If replacement of a constant velocity joint

becomes necessary, the complete axle (half

shaft) may be the only service option.

2.

Preparation for removal of a rear axle:

2a. If an impact wrench is unavailable:

•

Engage the differential lock and apply the park-

ing brake.

•

Loosen the lug nuts on the wheel driven by the

axle that is to be replaced using a 3/4” wrench.

2b. Lift and safely support the rear of the vehi-

cle.

2c. Tilt the cargo box up.

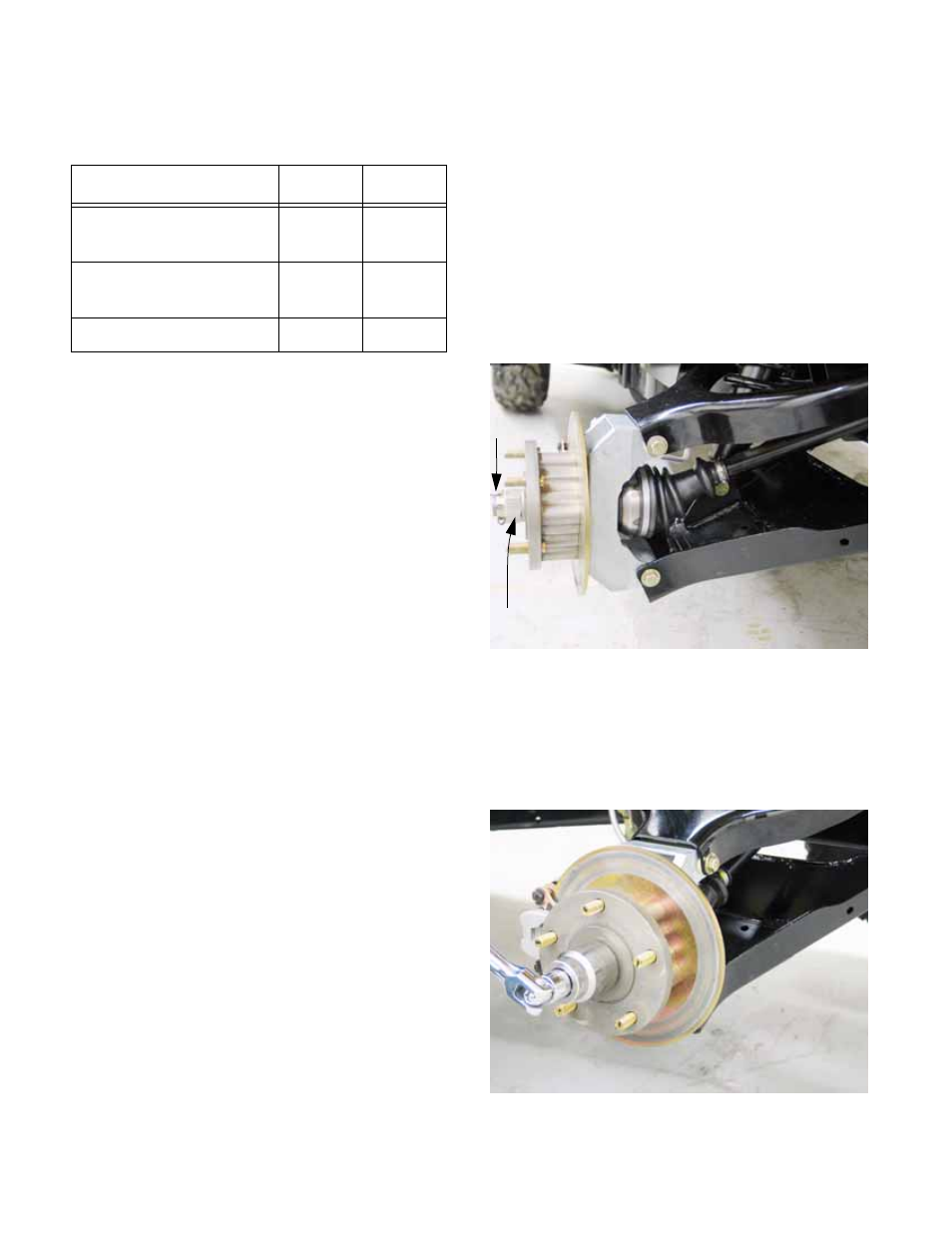

2d. Remove the rear wheel. See Figure 3.56.

3.

Remove and discard the cotter pin that locks the

axle nut.

4.

Remove the axle nut and flat washer using a 1-

5/16” wrench. Reinstall the nut finger-tight to

protect the threads. See Figure 3.57.

Item

ft-lbs

N-m

Torque bracket to

frame

16-20

22-27

Torque bracket to dif-

ferential

20-22**

27-30**

Differential to frame

32-36** 43-49**

Figure 3.56

Axle nut

Cotter pin

Figure 3.57