Chapter 2- drive system: cvt and transfer case – Cub Cadet 4 x 4 Volunteer User Manual

Page 59

Chapter 2- Drive System: CVT and Transfer Case

55

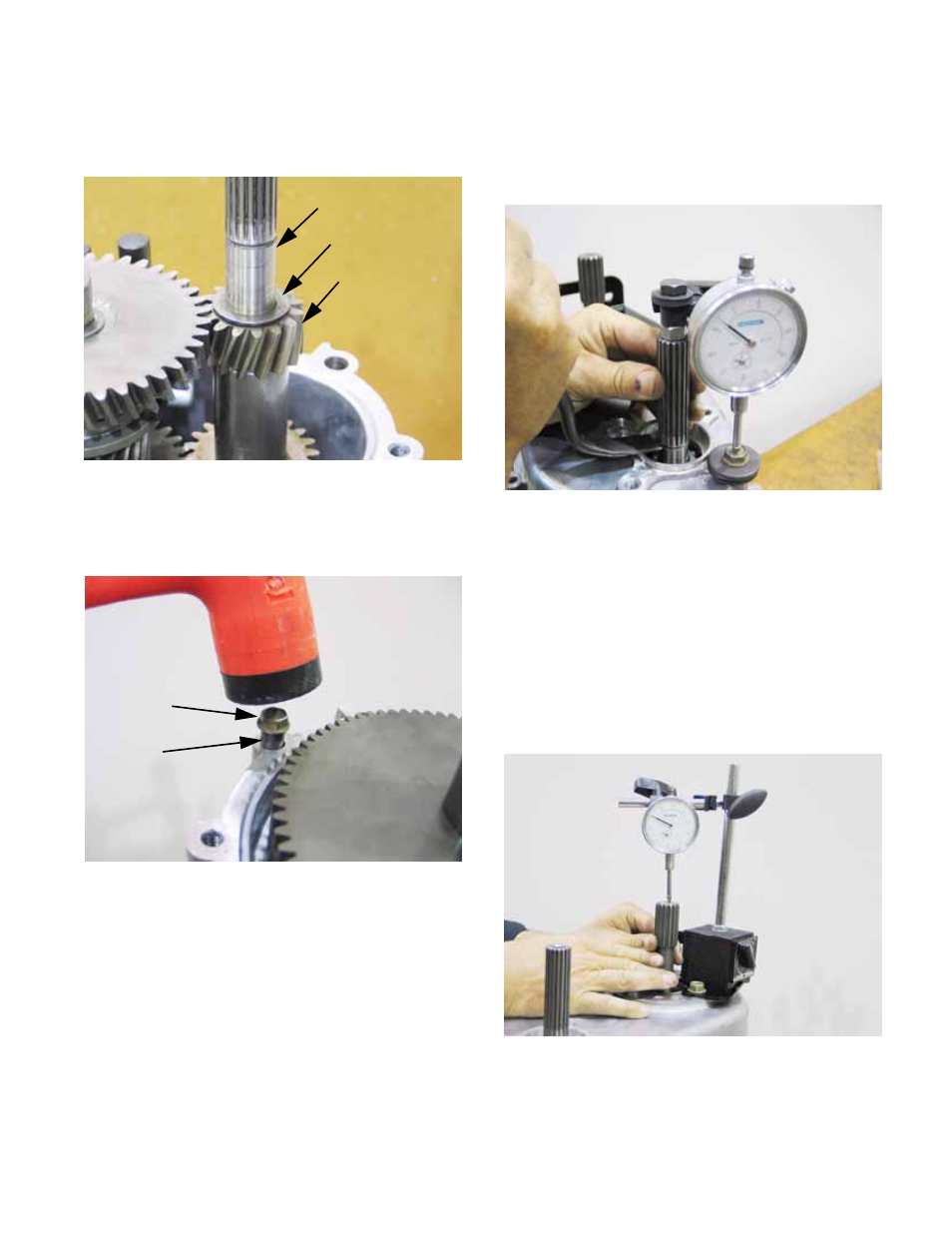

3y. Install the low pinion on the input shaft, fol-

lowed by the .060” (1.52mm) flat washer.

See Figure 2.134.

3z. Install the alignment dowels in the

untapped holes of the mating surface of

the right side case half. See Figure 2.135.

3aa. Lower the left side case half over the gear

set, so the sealing surfaces of the two

case halves meet.

3ab. Fasten the two case halves together using

four of the 5/16”-18 screws previously

removed. Tighten the screws “snug” but

they need not be torqued.

Figure 2.134

Input shaft

Flat washer

Low pinion

Figure 2.135

Bolt used

as a driver

Alignment

dowel

4.

Checking and final assembly:

4a. Affix a dial indicator to the input shaft, so

that it reads against the case.

See Figure 2.136.

4b. Work the input shaft up and down to get

and end-play measurement on the dial

indicator. End play should be less than

.009” (.23mm) without pre-loading the

input shaft bearing.

•

If end play is greater than .009” add .010”

(.254mm) shim P/N: 736-0563 to correct.

4c. Affix the dial indicator to read the end-play

of the axle shaft. A mag-base is suitable.

See Figure 2.137.

Figure 2.136

Checking input shaft end-play

Figure 2.137

Checking axle

shaft end-play