Chapter 5 - rear suspension – Cub Cadet 4 x 4 Volunteer User Manual

Page 174

Chapter 5 - Rear Suspension

170

14.

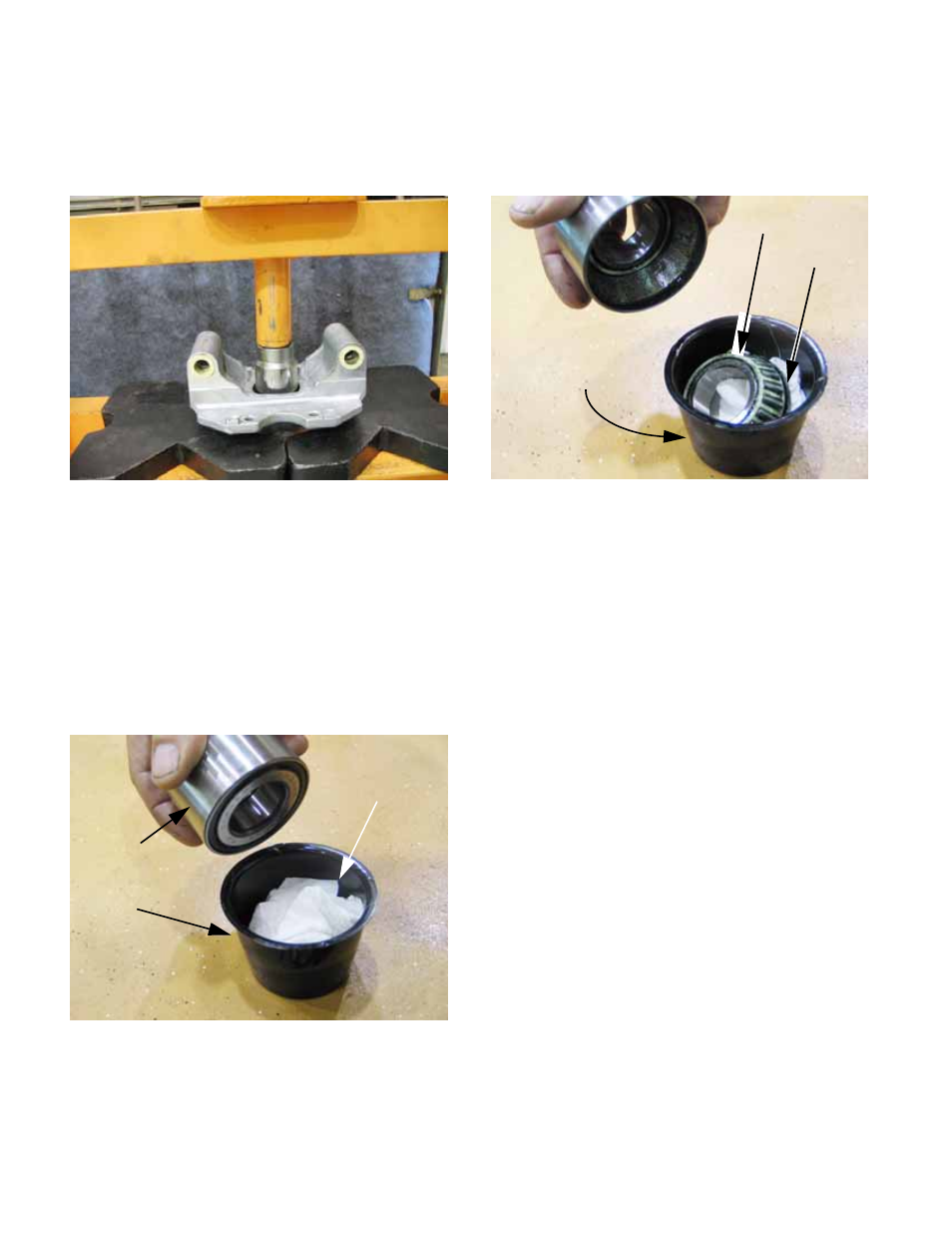

Press the bearing assembly using a round arbor

that has an outside diameter of roughly 2.125”

(5.39cm), pressing against the outer edge of the

cup. See Figure 5.28.

15.

The bearing assembly will come out with the

bearing cones captive, held in by the seals.

16.

To remove the bearings and seals:

16a. Thoroughly clean the inside of one of the

utility vehicle’s hub-caps.

16b. Place a clean piece of paper towel inside

the hub-cap, followed by the bearing

assembly. The towel will absorb some of

the shock. See Figure 5.29.

16c. Strike the hubcap on top of a work bench

with sufficient force to cause the bearing

cone to dislodge the seal.

See Figure 5.30.

NOTE: Keep track of which bearing was in

which side of the cup. While the bearing cones

are identical, they will wear into the cups with

usage, and the bearing cones should be kept

running in their original cups.

16d. Remove the first bearing cone from the

hub-cap.

16e. Turn the bearing assembly over, and

repeat for the second bearing cone and

seal.

17.

Clean and inspect the bearing cones and cup. If

any one part is damaged, replace the complete

wheel set.

18.

Pack the bearings with wheel bearing grease.

Figure 5.28

Figure 5.29

Wheel

bearing

assembly

Hub cap

Paper towel

Figure 5.30

4X4 hub cap

Bearing cone

seal