At-wheel components, Chapter 6 - hydraulic brakes – Cub Cadet 4 x 4 Volunteer User Manual

Page 182

Chapter 6 - Hydraulic Brakes

178

Brake drag / pulling (if at front caliper)

•

Caliper frozen on slide pins: After a long

period of dis-use or extremely gentle use, the

calipers may have become stuck on the slide

pins by corrosion or debris.

When pressure is applied to the piston in the cal-

iper, the inside pad contacts the rotor, and the

body of the caliper normally slides in the oppo-

site direction, pulling the second brake pad

against the outside of the brake rotor.

If the caliper is frozen on the pins, the inboard

brake pad will drag on the inner surface of the

brake rotor. Accelerated wear of the inboard

pads and rotor surface of any caliper are a tell-

tale sign of this condition.

•

Caliper piston stuck in bore. This is an

unusual problem, but it can happen on any disc-

brake design. Accelerated wear of both pads on

any single rotor is the primary indicator. If the

vehicle is operated for any length of time, the

rotor surfaces will be blued from over-heating.

•

Damaged brake line. After many years of use, it

is possible for the interior lining of some flexible

hoses to disintegrate or “implode”. This will

cause sluggish action in both directions. The

caliper(s) on the effected wheel(s) will apply

slowly and release slowly. Typical customer

complaint if a front brake line is effected will be

that the steering wheel pulls in one direction

while the operator applies the brakes, but pulls

in the opposite direction when they accelerate

away from a dead stop.

•

Master cylinder / brake pedal not returning.

This would most likely result in brake drag accel-

erated wear and blued rotors at all four wheels.

Check for bound pedal linkage. Do not over-

look the possibility that the operator may be rest-

ing their left foot on the pedal.

AT-WHEEL COMPONENTS

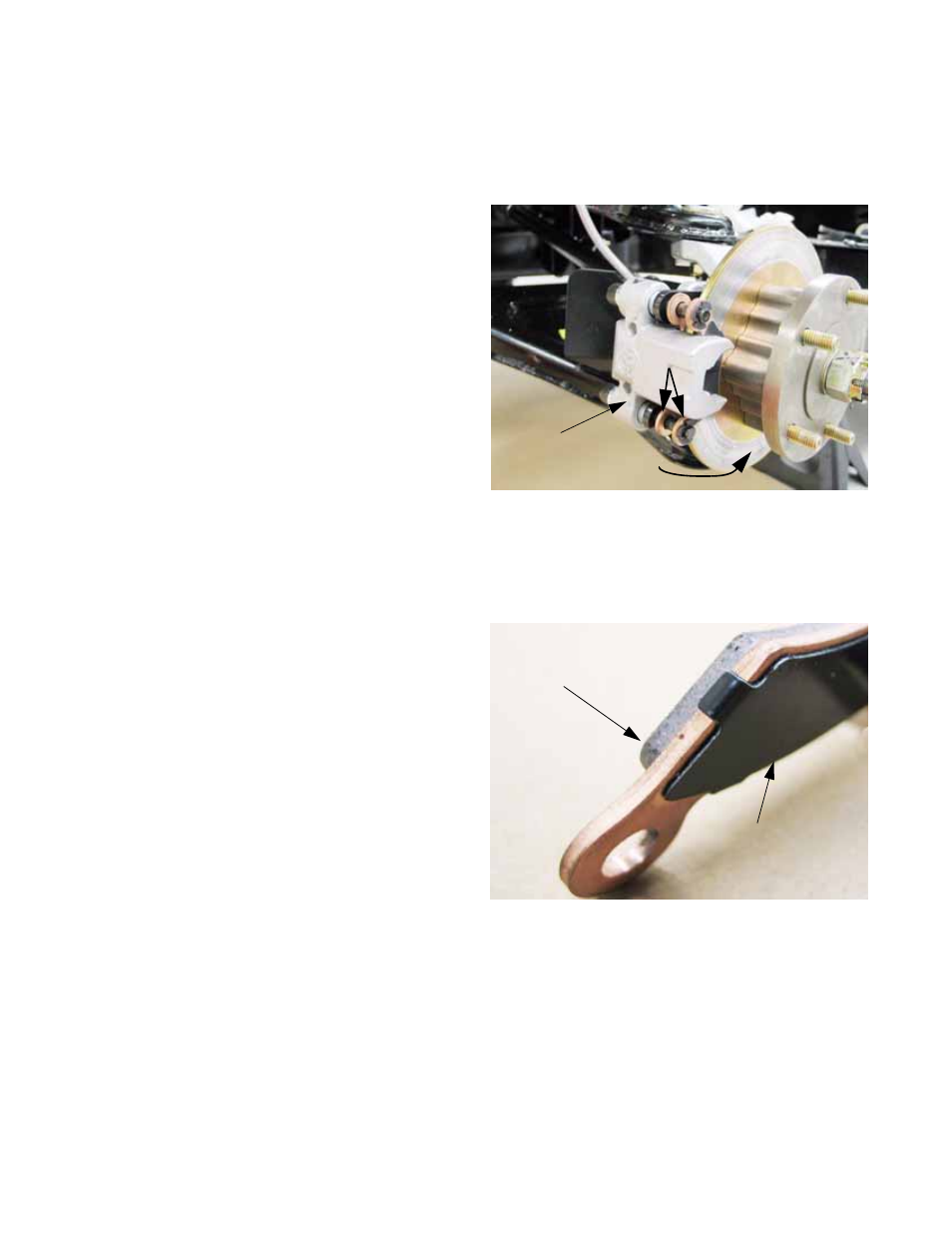

The brake calipers (single-piston, floating) are identi-

cal front to rear, and the pad replacement method is

identical as well. See Figure 6.11.

Each brake pad has an anti-squeal plate bonded to the

back side of the pad. Original thickness of the friction

material is roughly .156” (4mm).

See Figure 6.12.

•

The anti-squeal plate is attached by adhesive

and clips.

•

The clips extend roughly .020” (.50mm) over the

friction surface side of the pad, and act as an

audible wear sensor when the friction material is

worn to less than .020”

•

Replace the pads when the friction material

thickness is less than .040” (1mm).

Figure 6.11

Front brake caliper

Brake pads

Brake rotor

Figure 6.12

Brake pad

Anti-squeal plate