Cub Cadet 4 x 4 Volunteer User Manual

Page 123

Chapter 3 - Drive System: Drive Shafts and Differentials

119

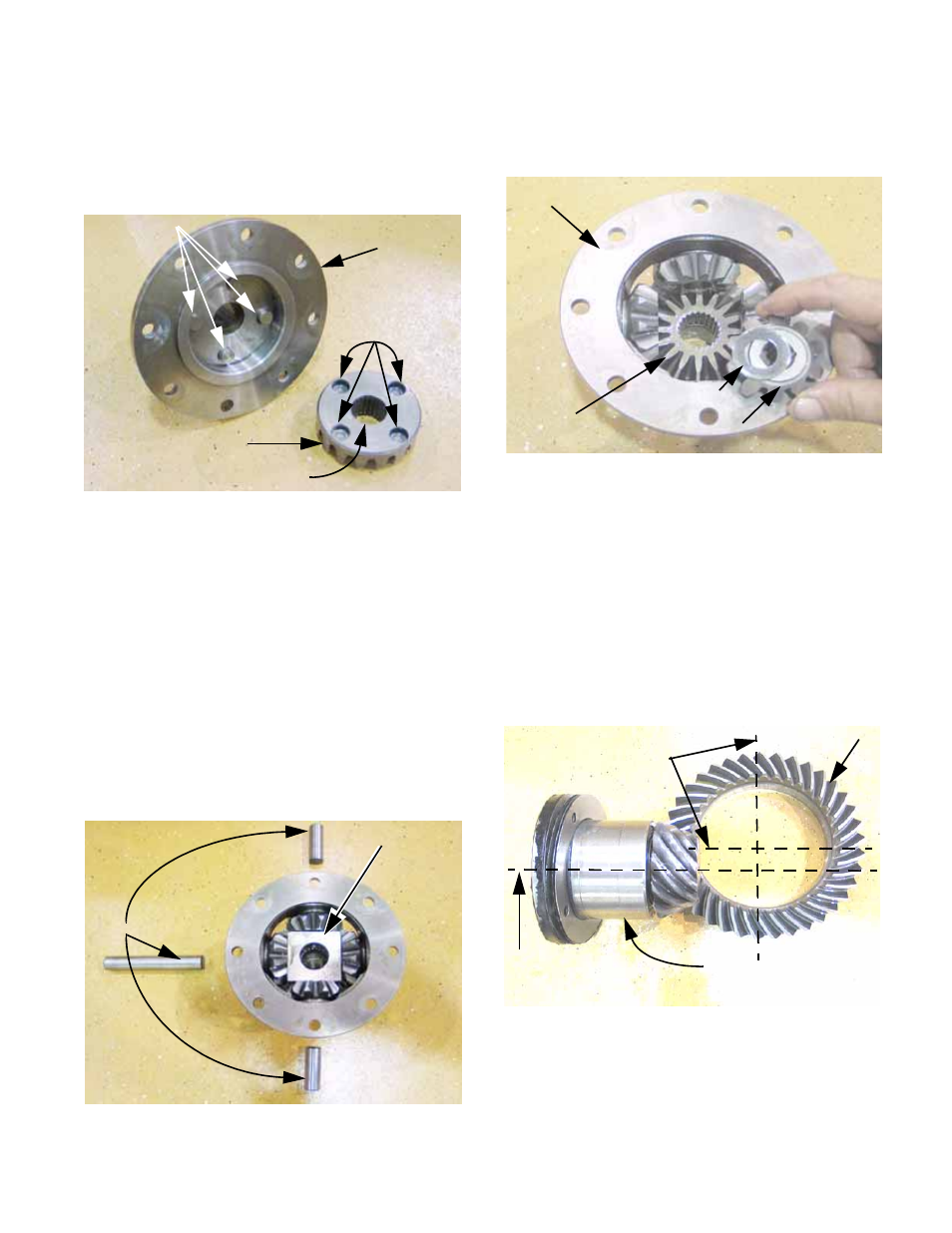

5d. The four pins on the differential lock collar

extend through the differential side plate

when the lock is engaged. This locks the

16-tooth bevel gear to the differential side

plate. See Figure 3.83.

•

The 16-tooth miter gear that resides in the side

plate of the differential is splined: it transfers

drive torque to the right-side axle.

•

Locking one miter gear effectively locks the

whole miter gear set, preventing the wheels from

rotating forward or back in relation to one-

another. The rear wheels are forced to rotate at

the same speed.

5e. The large side of the differential body con-

tains a set of four 10-tooth miter gears.

They are located in a central block by

three cross-pins: One long pin and two

short pins. See Figure 3.84.

Figure 3.83

16-tooth miter gear

Splined I.D.

4 holes for

lock pins

Differential

side-plate

4 differential

lock pins

Figure 3.84

Cross pins

Central block

5f. With the block and cross-pins removed, the

four 10-tooth meter gears can be lifted-out

of the differential body. See Figure 3.85.

•

Thrust washers are located between each 10-

tooth miter gear and the differential body.

•

The 16-tooth miter gear that resides in the base

of the differential body is splined: it transfers

drive torque to the left-side axle.

6.

On assembly, the shims will generally be placed

back in their original locations. If the order has

been lost, it will be necessary to re-establish

proper alignment between the pinion gear and

the ring gear. See Figure 3.86.

•

The center-line of the pinion gear does not align

with the centerline of the ring gear.

Figure 3.85

16-tooth

miter gear

Thrust washer

10-tooth miter gear

Differential

body

Figure 3.86

Ring gear

Pinion gear cartridge

Pinion gear

center-line

center-lines

Ring gear