Cub Cadet 4 x 4 Volunteer User Manual

Page 105

Chapter 3 - Drive System: Drive Shafts and Differentials

101

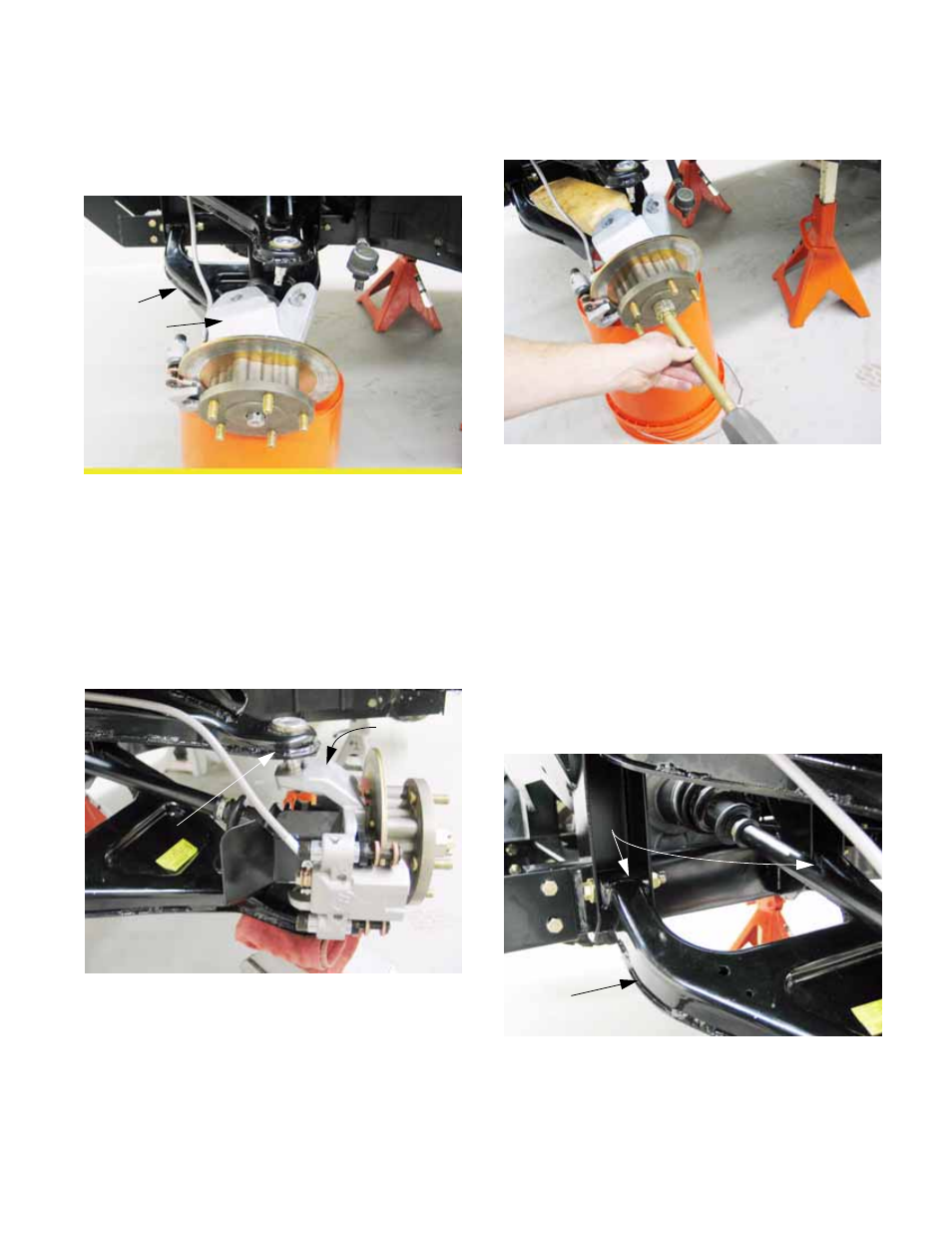

3d. Support the lower control arm and the hub

with enough stability that they will not fall,

yet allow some freedom of movement.

See Figure 3.33.

CAUTION: Do not allow the brake line to sup-

port any weight or take any pulling force.

3e. Separate the upper ball joint from the hub.

A ball joint separator of a heavy cold

chisel can be driven between the arm and

the hub to wedge the pieces apart.

See Figure 3.34.

CAUTION: Do not strike the hub casting to

release the tie rod end.

3f. Loosely thread the axle nut back onto the

end of the axle to help prevent damage to

the threads.

Figure 3.33

Lower

control

arm

Front hub

Figure 3.34

Upper ball joint

Front hub

3g. Use a soft drift to drive the axle out of the

hub. See Figure 3.35.

NOTE: Positioning a length of 2 X 4 dimensional

lumber to brace the hub will make the job easier.

NOTE: Disconnecting one ball joint does not

provide enough clearance to allow the driveshaft

to come out. At this point, the lower ball joint

may be disconnected, or the lower control arm

can be removed from the vehicle with the hub.

It is generally easier to remove the control arm.

4.

Remove the lower control arm:

4a. Remove the nuts and bolts that hold the

lower control arm to the frame using a pair

of 9/16” wrenches. See Figure 3.36.

NOTE: The bolts enter from the front, nuts to the

rear. The front bolt has a flat washer under it’s

head.

Figure 3.35

Figure 3.36

Lower

control arm

Connection

points to

frame