Chapter 2- drive system: cvt and transfer case – Cub Cadet 4 x 4 Volunteer User Manual

Page 20

Chapter 2- Drive System: CVT and Transfer Case

16

4b. Place the transfer case in H position, and

set the parking brake.

4c. Loosen the bolt that holds the driven ele-

ment to the input shaft using a 9/16”

wrench.

NOTE: Hold the driven element from rotating

using a pin spanner, if needed.

4d. Remove the bolt and washers.

4e. At this point, the driven element may be

slipped off of the transfer case input shaft.

5.

CVT Installation

NOTE: The driving element and driven element

can be installed individually, then the belt can be

rolled-on as described in the belt removal sec-

tion of this chapter.

Alternatively, both elements and the belt can be

installed all-at-once using a simple wood-block

tool. This method is described in the following

steps.

Preparation and torque specs remain the same

for both methods.

6.

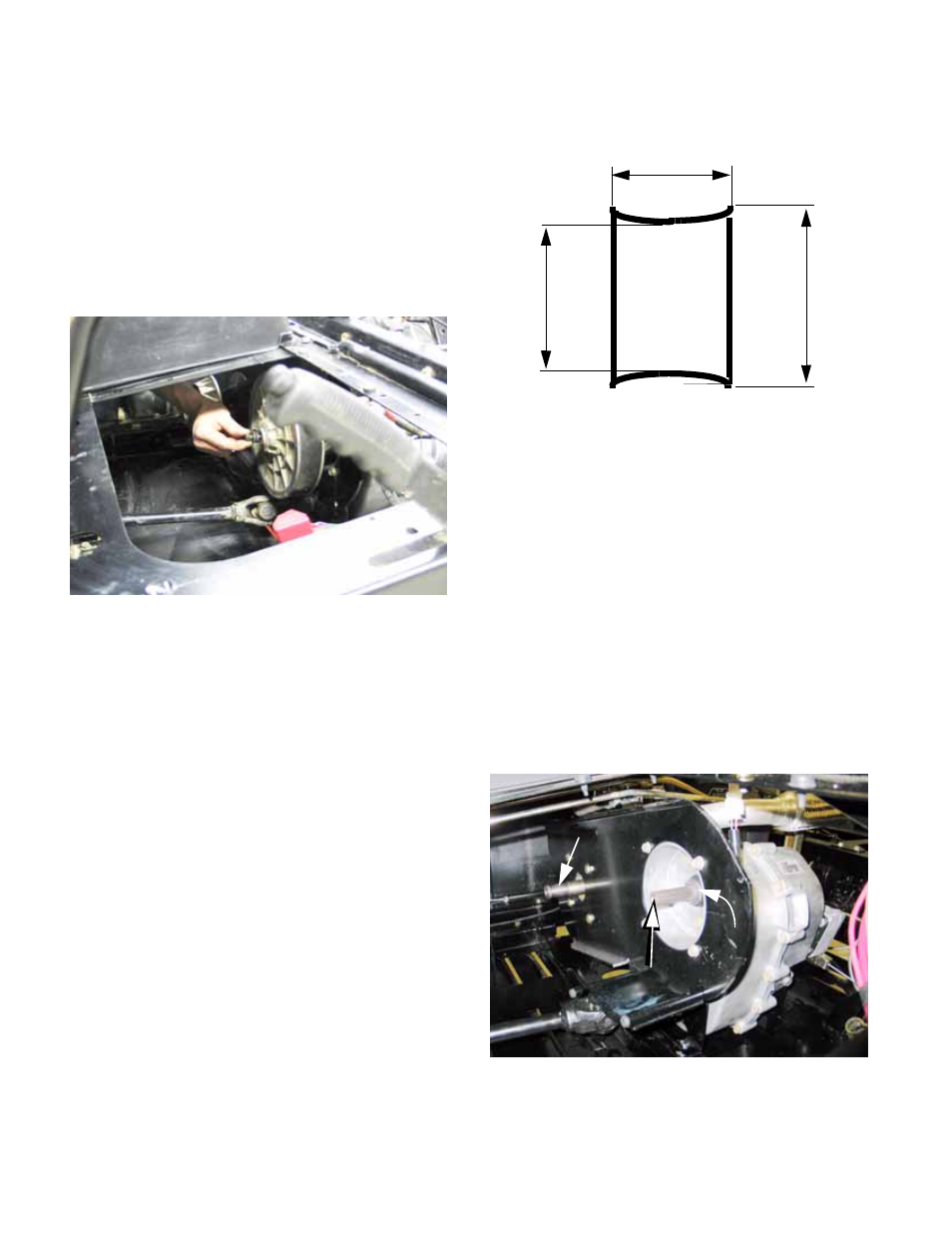

Make the wood block spacer as described in the

accompanying illustration. See Figure 2.19.

6a. Prepare the CVT for installation:

•

Clean the shafts and the surrounding area

before installing the CVT.

•

Confirm the presence of the .060” (1.5mm)

spacer on the shaft between the driven element

and the transfer case housing.

•

A small amount of anti-seize compound may be

used on the splined joint between the input shaft

of the transfer case and the driven element.

•

The tapered joint between the driving element

and the crankshaft must be clean and dry.

Figure 2.18

Figure 2.19

4-3/8”

NOTE: BLOCK ENDS MAY BE

V-SHAPED OR CURVED

(8.6CM)

3-1/2” (8.9CM)

(13.1CM)

5-1/8”

Figure 2.20

Tapered shaft

Splined shaft

Spacer