Application examples, Speed control, Application−specific configuration – Lenze 8200 motec frequency inverter 0.25kW-7.5kW User Manual

Page 196: Basic settings

Application examples

Speed control

13−11

l

EDB82MV752 EN 5.2

Application−specific configuration

·

Basic settings.

(

^ 6−2)

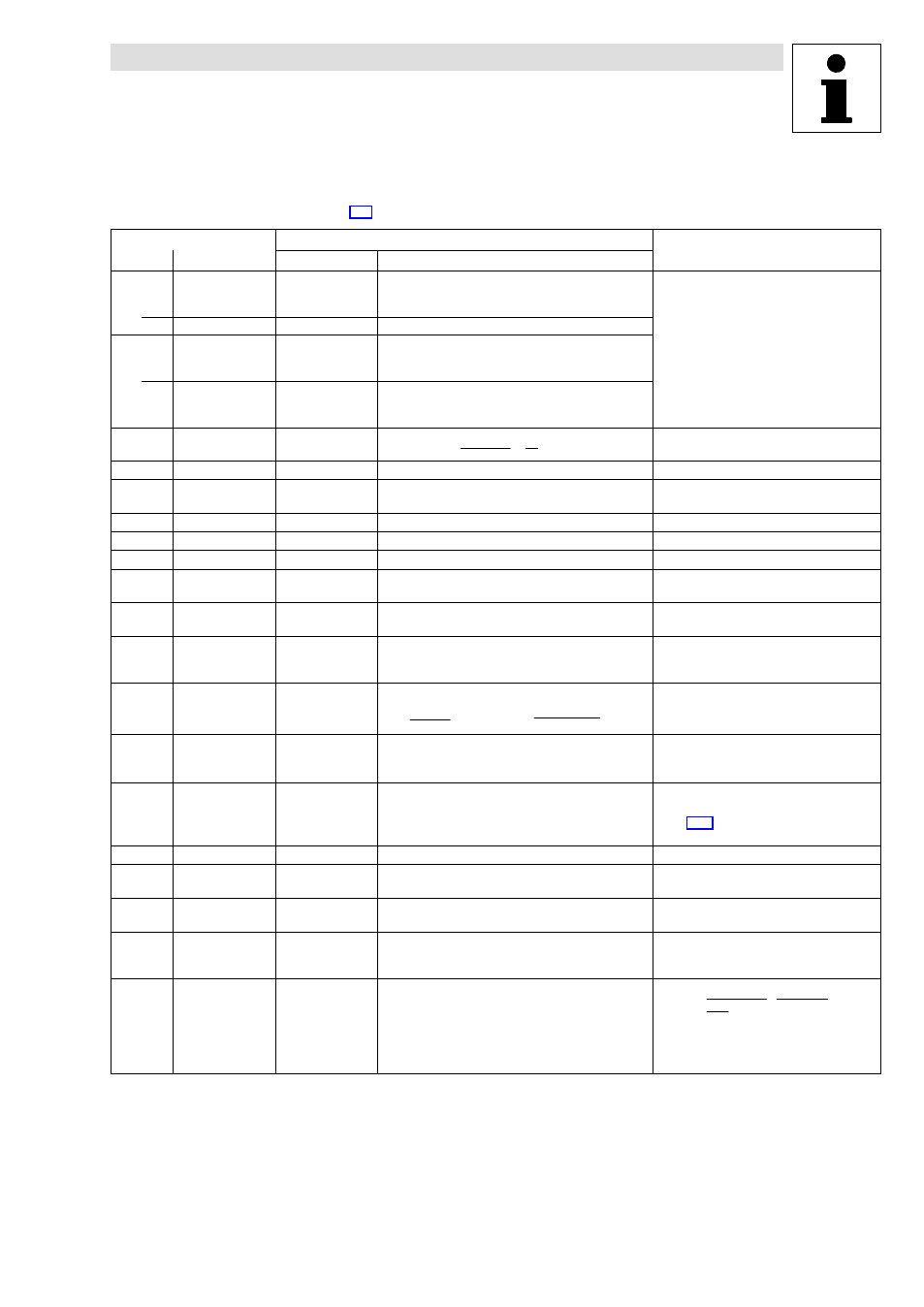

Code

Settings

Important

Value

Meaning

C0410 Free configuration

of digital input

signals

Configuration of frequency input X3/E1

24 DFIN1−ON

−1−

C0412 Free configuration

of analog input

signals

Analog signal source

5 Actual process

controller value

(PCTRL1−ACT)

−2−

C0011 Maximum output

frequency

(1

)

C0074 [%]

100

)

@

p

60

@ n

max

p = number of pole pairs

n

max

= required maximum speed [rpm]

C0014

↵ Operating mode

−2

V/f characteristic control

Dynamics in "vector control" mode too low

C0019 Operating threshold

auto DCB

approx. 0.5 Hz

Adaptation to the application

C0021 Slip compensation

0 %

No slip compensation with controlled operation

C0035*

↵ DCB selection

−1−

Brake current selection under C0036

C0036 Voltage/current DCB

50 ... 100 %

Adaptation to the application

C0070 Process controller

gain

1 ... 15

5 = typical

C0071 Process controller

reset time

50 ... 500 ms

100 ms = typical

C0072 Differential

component of

process controller

0

Not active

C0074 Process controller

influence

2 ... 10 %

S

N

+

n

0

* n

N

n

0

Example

S

N

+

1500

* 1400

1500

+ 6.67 %

·

Adaptation to the application

·

Set 200% rated motor slip (2 * S

N

)

C0106 Hold time auto DCB

1 s

·

Guide value

·

Afterwards the controller sets controller

inhibit

C0181* Process controller

setpoint 2

(PCTRL1−SET2)

·

Adaptation to the application

·

Selection with keypad or PC

·

^ 7−53: Further options for selecting the

setpoint

C0196*

↵ Activation auto DCB

−1−

DCB active when C0050 < C0019 and setpoint < C0019

C0238

↵ Frequency

precontrol

−1−

With frequency feedforward control

C0239

↵ Lower frequency

limitation

0 Hz

unipolar, no reversal of rotation direction

C0425

↵* Configuration of

frequency input

X3/E1 (DFIN1)

Set C0425 so that, at maximum motor speed,

the frequency supplied by the encoder is lower

than f

max

C0426* Frequency input

gain X3/E1, X3/E2

(A) (DFIN1−GAIN)

100

−1500.0

{0.1 %}

1500.0

C0426

+

f

N

(C0425)

nmax

60 s

@ incńrev

@

C0011

* f

s

C0011

@ 100 %

·

n

max

= maximum motor process speed in

rpm

·

f

s

= slip frequency in Hz