Application examples, Pressure control, Application−specific configuration – Lenze 8200 motec frequency inverter 0.25kW-7.5kW User Manual

Page 191

Application examples

Pressure control

13−6

L

EDB82MV752 EN 5.2

Application−specific configuration

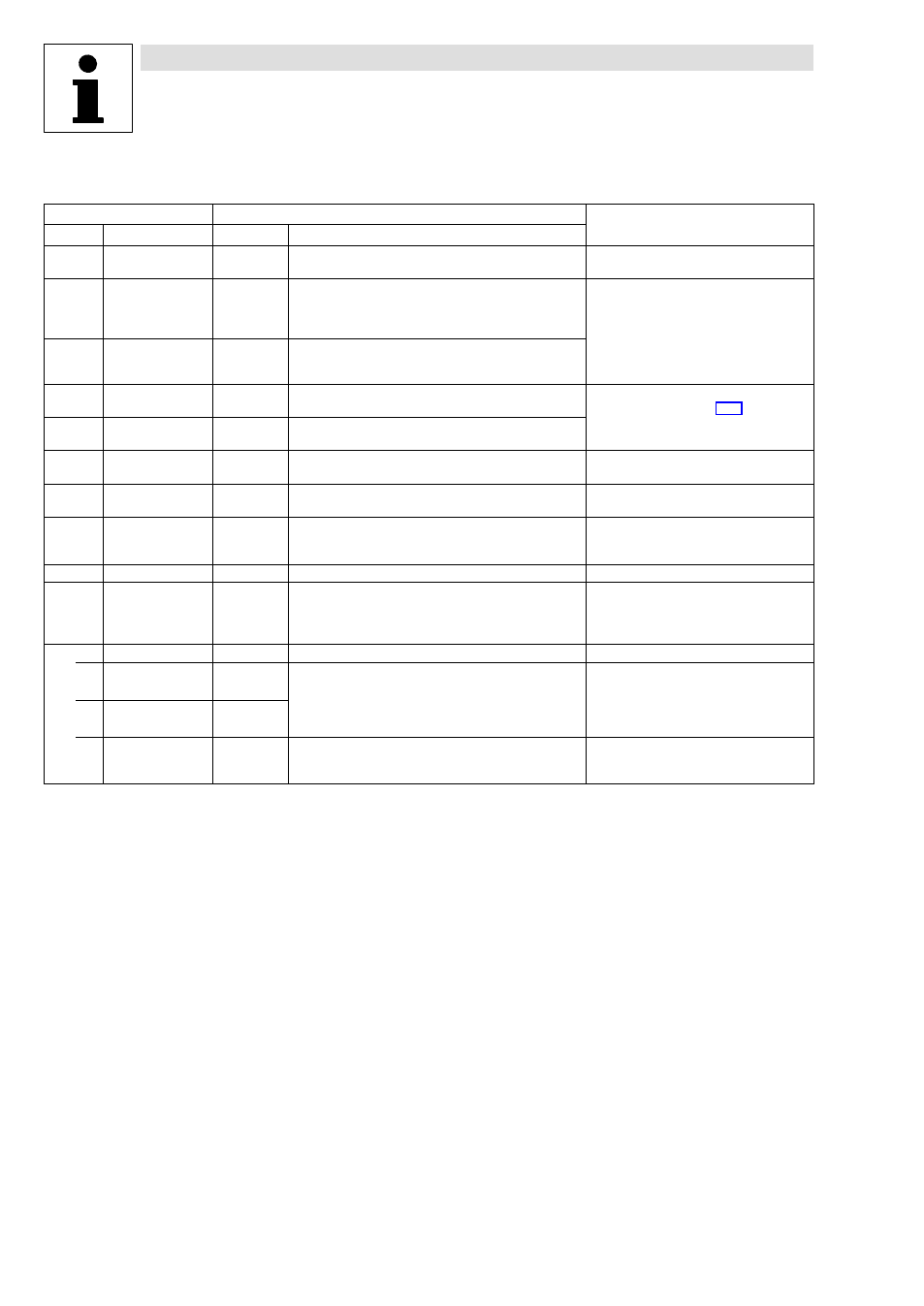

Code

Settings

Important

No.

Designation

Value

Meaning

C0014 Operating mode

3

V/f characteristic control V

~f

2

square−law characteristic with constant V

min

boost

C0019 Operating threshold −

automatic DC

injection brake (auto

DCB)

0

Automatic DC injection brake is deactivated

If the lower frequency limitation is activated

(C0239) or if C0181 is used as controller

setpoint (C0145), the automatic DC injection

brake must be deactivated!

C0106 Hold time − automatic

DC injection brake

(auto DCB)

0

Automatic DC injection brake is deactivated

C0070 Process controller

gain

1.00

Lenze default setting

Adapt to process, if required.

à

Further information:

^ 7−50 ff.

C0071 Process controller

reset time

100

Lenze default setting

C0074 Process controller

influence

100.0

0.0

{0.1 %}

100.0

C0145 Source of process

controller setpoint

1

Setpoint from C0181 (PCTRL1−SET2)

Automatic DC injection brake (auto DCB) must

be deactivated with C0019 = 0 or C0106 = 0

C0181 Process controller

setpoint 2

(PCTRL1−SET2)

−650.00

{0.02 Hz}

650.0

C0238 Frequency precontrol

0

No feedforward control (only process controller)

Process controller has full influence.

C0239 Lower frequency

limitation

³ 0

Prevent reversed rotation

The value does not fall below the limit

independently of the setpoint.

Automatic DC injection brake (auto DCB) must

be deactivated with C0019 = 0 or C0106 = 0

C0412

Linking analog signal sources to internal analog signals

1 Setpoint 1

(NSET1-N1)

255

fixed free (disconnect from analog input)

The analog input of the standard I/O (AIN1) is

linked factory−set to the speed feedforward

control. This connection must be separated so

that the input can be used for the analog

actual value (C0412/5).

2 Setpoint 2

(NSET1-N2)

255

5 Actual process

controller value

(PCTRL1−ACT)

1

Analog input X3/8 of the standard I/O

Actual pressure value