Application examples, Pressure control – Lenze 8200 motec frequency inverter 0.25kW-7.5kW User Manual

Page 190

Application examples

Pressure control

13−5

L

EDB82MV752 EN 5.2

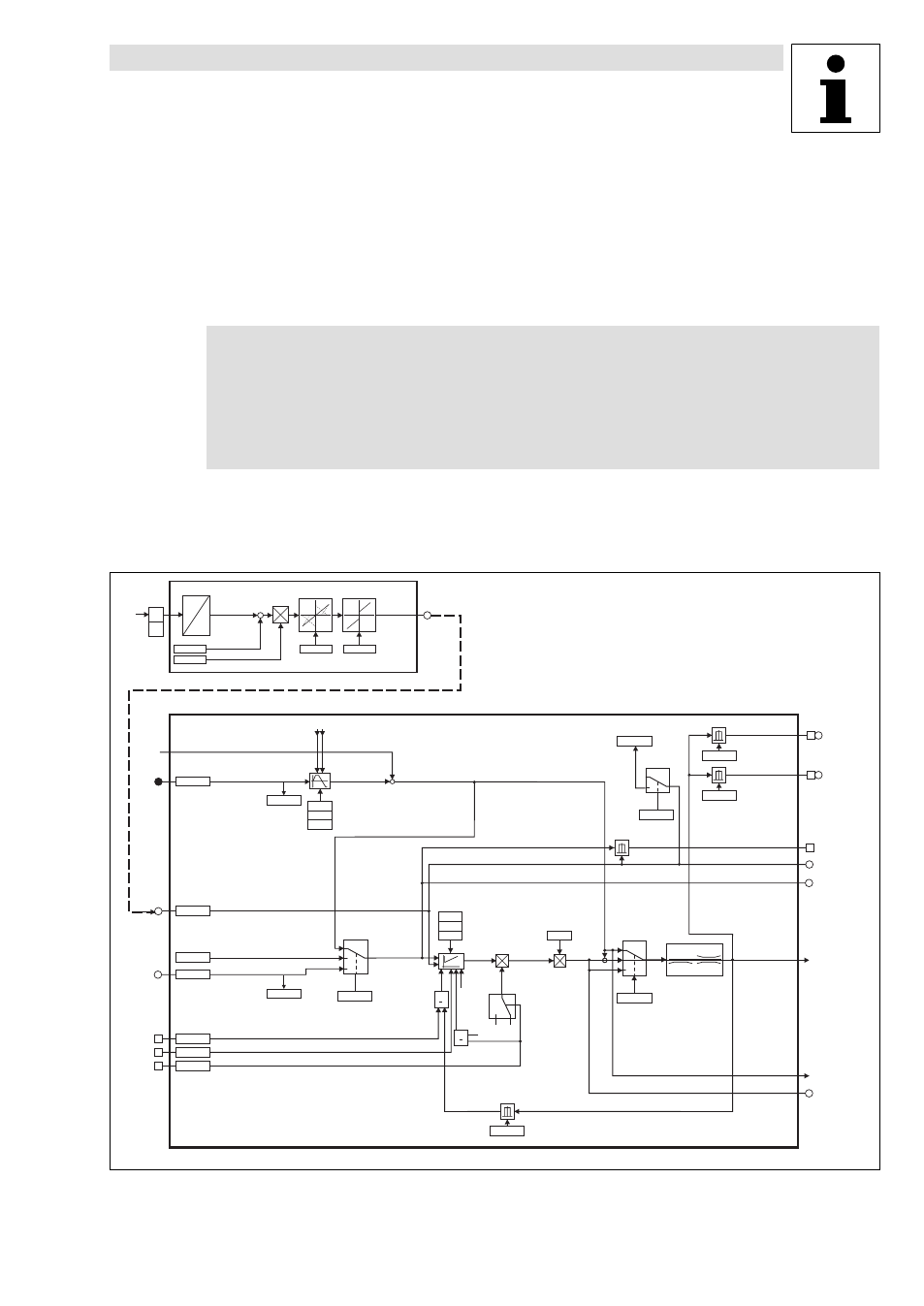

The following examples show a simple pressure control with the 8200 vector frequency inverter or

8200 motec using the internal process controller.

The setpoint can either be defined in a fixed way via the code C0181 (example 1) or variably with

the motor potentiometer function (example 2).

Application example

A centrifugal pump (quadratic load characteristic) is to maintain constant pressure in a pipeline

system (e.g. water supply for private households or industrial plants).

)

Note!

l

For this example, the controller must be equipped with a standard I/O since an

analog input for the actual pressure value is required.

l

If you want to select the pressure setpoint via an analog source, you need an

application I/O since two analog inputs are required. This variant will not be

considered in the following.

13.1.1

Example 1: Simple pressure control with fixed setpoint selection

The actual value is supplied via the analog input of the standard I/O

0 and linked to the controller

input (PCTRL−ACT). The setpoint is defined via code C0181

1.

PCTRL1

DCTRL1-QSP

DCTRL1-CINH

C0412/3

PCTRL1-NADD

C0105

C0220

C0221

+

C0181

PCTRL1-SET2

C0049

PCTRL1-RFG1

2

0

C0412/5

PCTRL1-ACT

C0412/4

PCTRL1-SET1

1

PCTRL1-SET3

C0145

C0071

C0070

C0072

1

>

C0410/18

PCTRL1-I-OFF

C0410/21

PCTRL1-STOP

C0410/19

PCTRL1-OFF

STOP

Imax,

Auto-DCB,

LU, OU

1

>

0

1

CINH, DCB

C0074

C0184

RESET

+

0

2

1

C0238

C0011

-C0011

PCTRL1-NOUT

PCTRL1-OUT

PCTRL1-QMIN

PCTRL1-NMIN

C0010

PCTRL1-ACT

C0017

PCTRL1-SET=ACT

PCTRL1-SET

NSET1-NOUT

C0138

C0239

2

0,1

C0238

C0051

+

2

1

PCTRL1-SET3

AIN1

+

AIN1-GAIN

+

AIN1-OFFSET

C0414/1

C0413/1

C0010

C0034

A

D

X3

AIN1-OUT

8

7

1

0

8200vec543

Fig. 13−2

Signal flow − overview