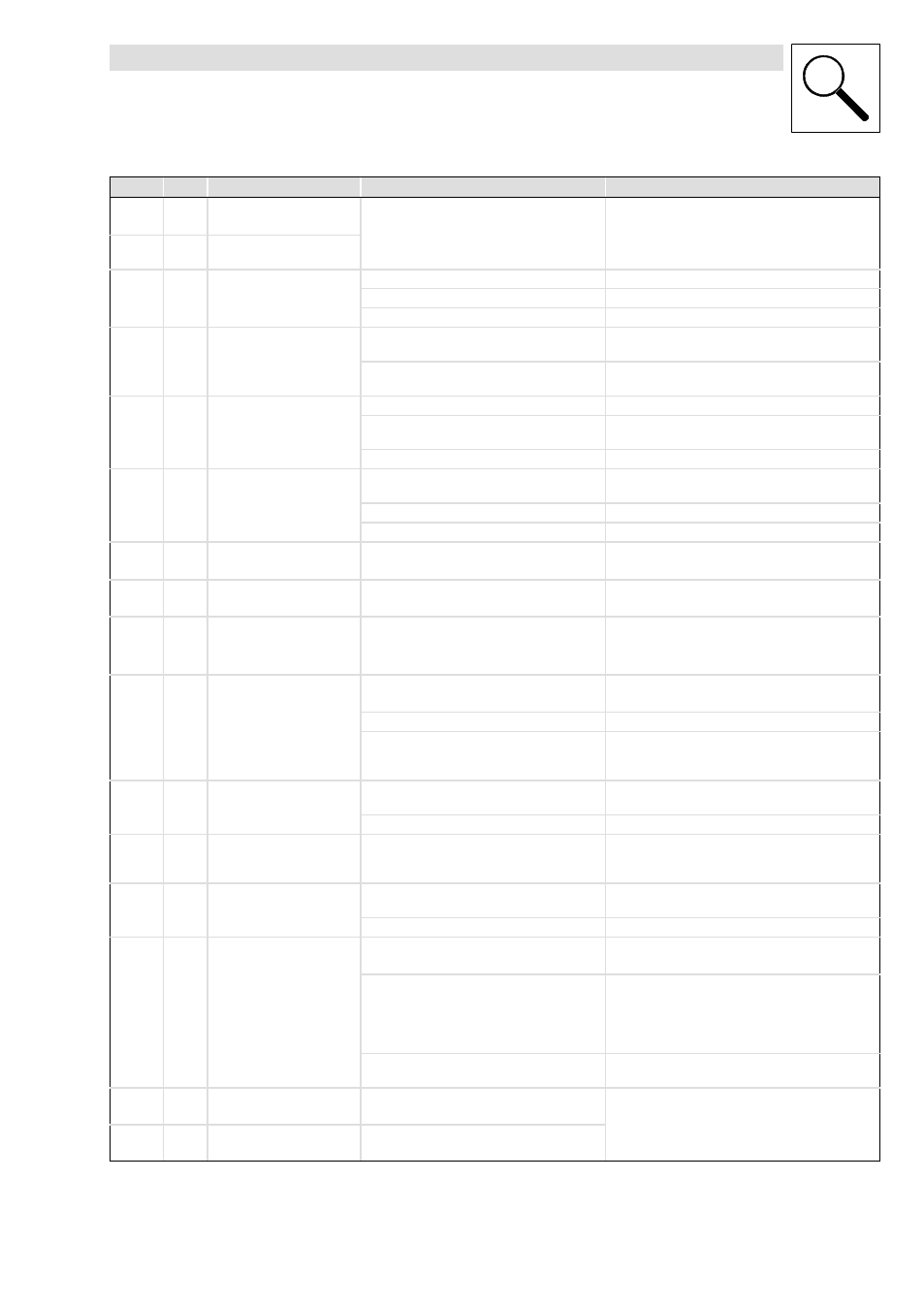

Troubleshooting and fault elimination, Error messages – Lenze 8200 motec frequency inverter 0.25kW-7.5kW User Manual

Page 172

Troubleshooting and fault elimination

Error messages

8−5

L

EDB82MV752 EN 5.2

Remedy

Cause

Fault

PC

1)

Keypad

LP1

a

32

Error in motor phase

(Display when C0597 = 1)

·

Failure of one/several motor phases

·

Motor current too low

·

Check motor supply cables

·

Check U

min

boost,

·

Connect motor with a corresponding power or adapt

motor with C0599

LP1

182

Error in motor phase

(Display when C0597 = 2)

LU

c

−

DC bus undervoltage

Mains voltage too low

Check mains voltage

Voltage in DC−bus connection too low

Check power supply module

400 V controller is connected to 240 V mains

Connect controller to correct mains voltage

OC1

a

11

Short circuit

Short circuit

·

Search for cause of short circuit; check motor cable

·

Check brake resistor and cable to brake resistor

Capacitive charging current of the motor cable too

high

Use shorter/low−capacitance motor cable

OC2

a

12

Earth fault

A motor phase has earth contact

Check motor; check motor cable

Capacitive charging current of the motor cable too

high

Use shorter/low−capacitance motor cable

Deactivate earth−fault detection for inspection purposes

OC3

a

13

Controller overload during

acceleration or short circuit

Acceleration time set is too short (C0012)

·

Increase acceleration time

·

Check drive dimensioning

Defective motor cable

Check wiring

Interturn fault in the motor

Check motor

OC4

a

14

Controller overload during

deceleration

Deceleration time set is too short (C0013)

·

Increase deceleration time

·

Check dimensioning of the external brake resistor

OC5

a

15

Controller overload during

steady−state operation

Frequent and too long overload

Check drive dimensioning

OC6

a

16

Motor overload (I

2

x t overload) Motor is thermally overload by e.g.

·

impermissible continuous current

·

Check drive dimensioning

·

frequent or too long acceleration processes

·

Check setting of C0120

OH

a

50

Heatsink temperature

> +85 °C

Ambient temperature is too high

Allow controller to cool and provide better ventilation

OH

e

−

Heatsink temperature

> +80 °C

Heatsink is very dirty

Clean heatsink

Impermissibly high currents or frequent and too

long acceleration processes

·

Check drive dimensioning

·

Check load, exchange rough−running, defective

bearings if necessary

OH3

a

53

PTC monitoring (TRIP)

(Display when C0119 = 1 or 4)

Motor too hot due to impermissibly high currents

or frequent and too long acceleration processes

Check drive dimensioning

No PTC connected

Connect PTC or switch off monitoring

OH4

a

54

Controller overtemperature

Controller too hot inside

·

Reduce controller load

·

Improve cooling

·

Check fan in the controller

OH51

203

PTC monitoring

(Display when C0119 = 2 or 5)

Motor too hot due to impermissibly high currents

or frequent and too long acceleration processes

Check drive dimensioning

No PTC connected

Connect PTC or switch off monitoring

OU

c

−

DC bus overvoltage

(Message or TRIP configurable

in C0310)

Mains voltage too high

Check supply voltage

OUE

a

22

Braking operation

·

Increase deceleration times

·

When operating with an external brake resistor:

– Check dimensioning, connection and supply cable

of the brake resistor

– Increase deceleration times

Earth leakage on the motor side

Check motor supply cable and motor for earth fault

(disconnect motor from the inverter)

Pr

a

75

Faulty parameter transmission

when using the keypad

All parameter sets are defective

Before enabling the controller, repeat the data transfer or

load the Lenze setting

Pr1

a

72

Faulty PAR1 transfer with

keypad

Parameter set 1 is defective