3 rated data of lenze brake resistors, Rated data of lenze brake resistors, Braking operation – Lenze 8200 motec frequency inverter 0.25kW-7.5kW User Manual

Page 182

Braking operation

11−3

L

EDB82MV752 EN 5.2

11.2.3

Rated data of Lenze brake resistors

Lenze brake resistors (IP65)

r

Continuous power*

Thermal capacity

Switch−on cycle

Cable cross−section

Weight

Order number

[

W]

[kW]

[kWs]

[mm

2

]

AWG

[kg]

ERBS470R150W

470

0.15

22.5

1:10

Brake for a maximum

of 15 s, then apply a

recovery time of at

least 135 s

0.5 ... 10

20 ... 6

1.3

ERBS240R300W

240

0.3

45

2.1

ERBS180R350W

180

0.35

53

2.1

ERBS100R625W

100

0.62

94

3.1

ERBS082R780W

82

0.78

117

3.6

*

The continuous power is a reference variable for selecting the brake resistor. Peak brake power is applied during braking (U

2

DC

/R)

Observe national and regional regulations

Tip!

·

The brake resistors are fitted with a thermostat (potential−free NC contact) as standard.

·

If required, several brake resistors can be connected in parallel or in series. (Caution: do not

fall below the lowest possible value!)

Installation instructions

·

Brake resistors may overheat, possibly a brake resistor may burn. Therefore, mount the brake

resistors in such a way that the possibly very high temperatures may not cause any damage.

·

Provide a safety shutdown when the brake resistor overheats!

·

Use temperature contacts of the brake resistor (e.g. T1 / T2) as control contacts to separate

the controller from the mains!

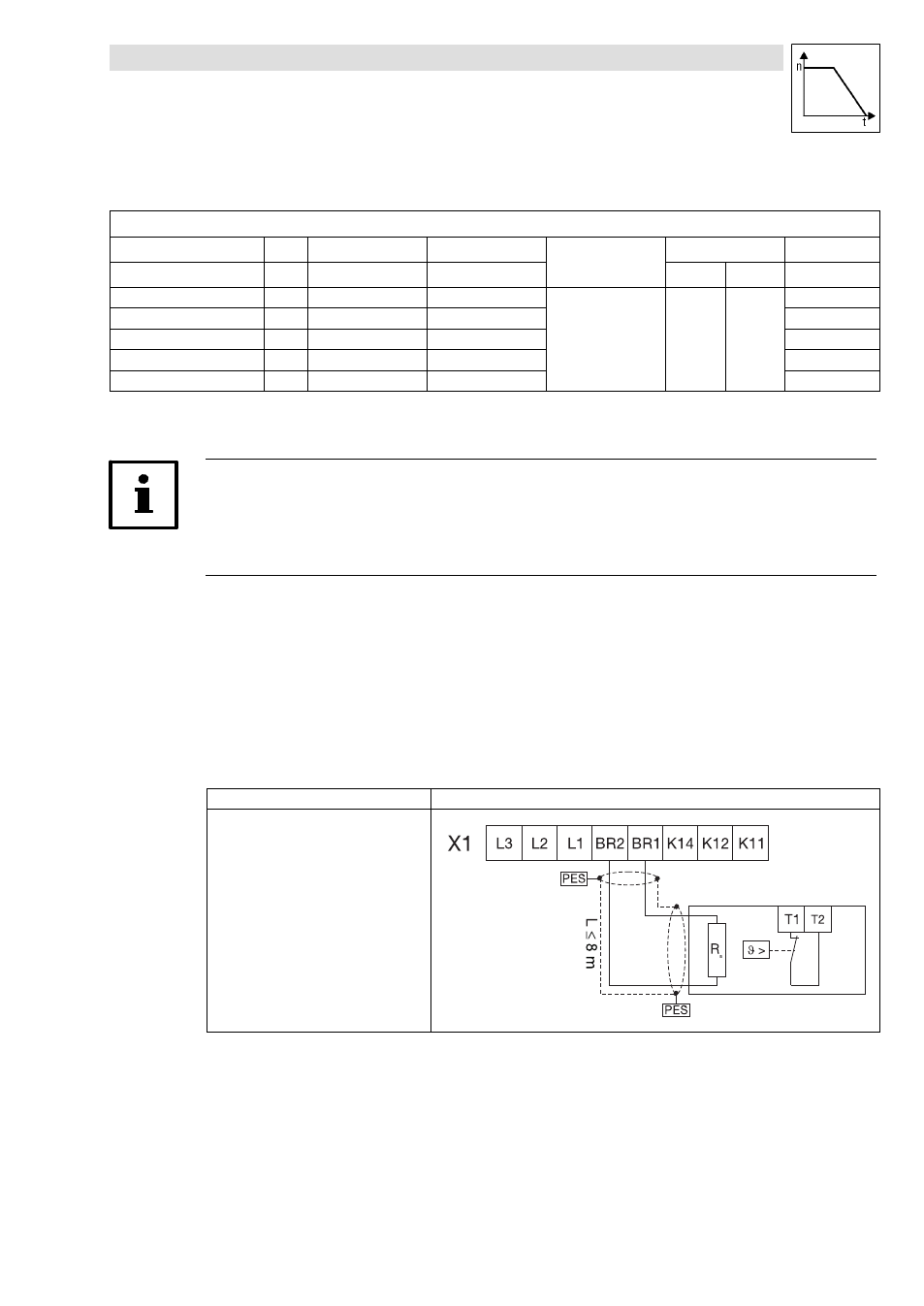

Connection to E82MV251_2B, E82MV371_2B

Procedure

Connection diagram

The brake resistor R

B

is connected to the

terminal strip X1 of the motec.

1. Open the motec.

2. Mount the cable connector for the cable

gland.

3. Unscrew the terminal strip X1 and remove

it from its support.

4. Connect the brake resistor to BR2 and

BR1.

5. Reconnect the terminal strip X1.