Appendix, Code table – Lenze 8200 motec frequency inverter 0.25kW-7.5kW User Manual

Page 224

Appendix

Code table

14−23

L

EDB82MV752 EN 5.2

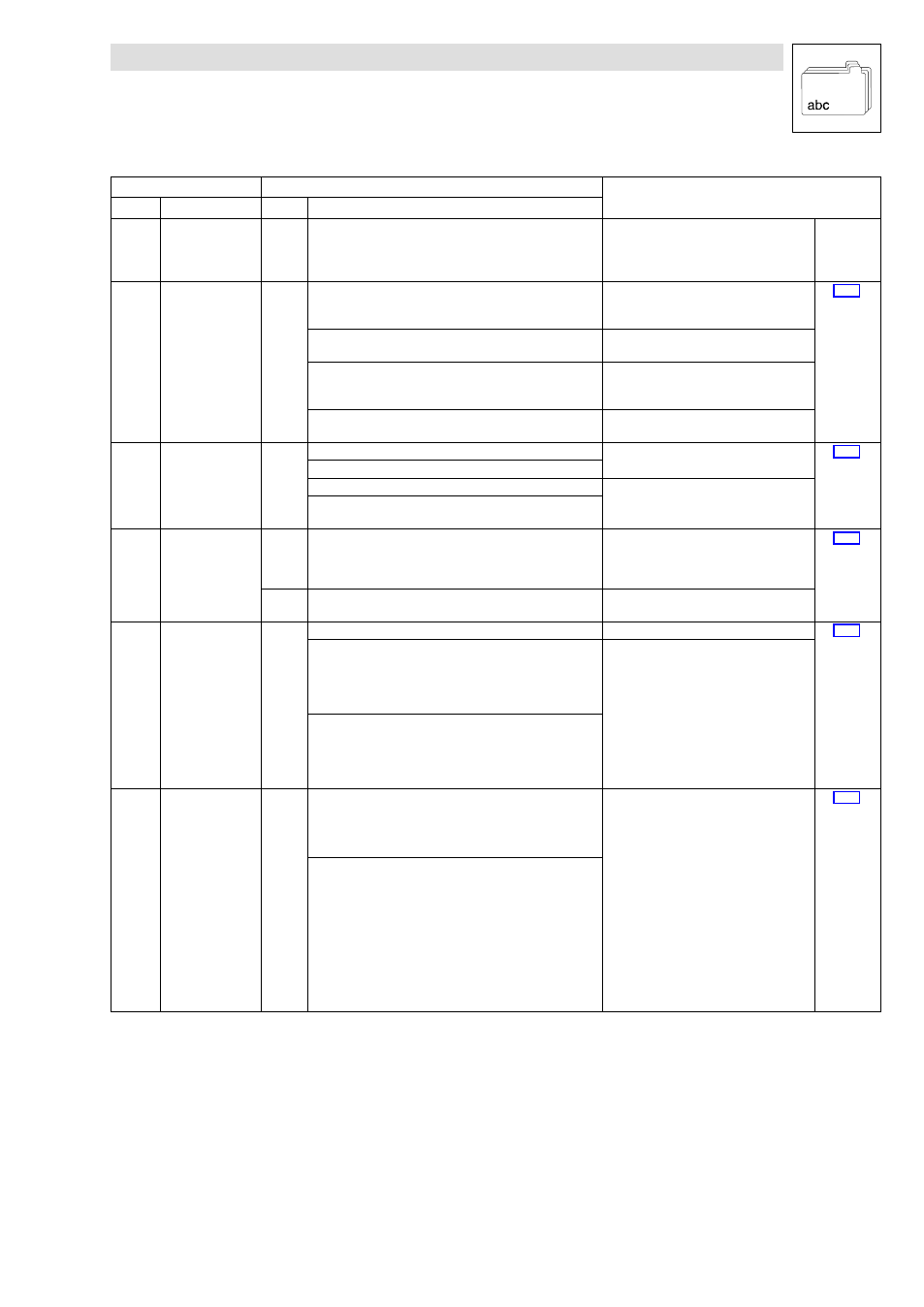

Code

IMPORTANT

Possible settings

No.

Selection

Lenze

Name

C0141*

Setpoint

normalisation

0.00

−100.00

{0.01 %}

100.00

The value set will be lost when

switching the mains!

Only effective if C0127 = 1

Reference: C0011

C0142

v

Start condition

1

0

Automatic restart after mains connection

inhibited

Flying restart not active

Start after HIGH−LOW−HIGH changes at

X3/28

^ 7−18

1

Automatic start, if X3/28 = HIGH

Flying restart circuit not active

2

Automatic restart after mains connection

inhibited

Flying−restart circuit active

Start after HIGH−LOW−HIGH changes at

X3/28

3

Automatic start, if X3/28 = HIGH

Flying restart circuit active

C0143*

v

Selection of

flying−restart

0

0

Max. output frequency (C0011) ... 0 Hz

Motor speed selected for the indicated

range

^ 7−18

1

Last output frequency ... 0 Hz

2

Frequency setpoint addition (NSET1−NOUT)

The corresponding value is input after

controller enable.

3

Act. process controller value (C0412/5) addition

(PCTRL1−ACT)

C0144

v

No temperature

depending

switching frequency

derating

1

0

No temperature−depending switching frequency

derating

When operating with a switching frequency

of 16 kHz it is also possible to derate it to 4

kHz. The behaviour can be changed under

C0310.

^ 7−14

1

Automatic switching frequency derating to 4 kHz,

if

J

max reaches

− 5 °C

C0145*

v

Process controller

setpoint source

0

0

Total setpoint (PCTRL1−SET3)

Main setpoint + additional setpoint

^ 7−53

1

C0181 (PCTRL1−SET2)

·

Setpoint selection not possible via

– JOG values

–

j

function of the keypad

– C0044, C0046 and C0049

– in connection with manual/remote

changeover, skip frequencies, ramp

function generator, additional setpoint

·

Activate the automatic DC−injection

brake (auto DCB) with C0019 = 0 or

C0106 = 0

2

C0412/4 (PCTRL1−SET1)

C0148*

s

Motor parameter

identification

0

0

Ready

Only when the motor is cold!

1. Inhibit controller, wait until drive is at

standstill

2. Enter the correct motor data under

C0087, C0088, C0089, C0090, C0091

(see motor nameplate).

3. Set C0148 = 1 by

v

4. Enable controller

The identification

– starts,

c

goes off

– the motor makes a high−pitched tone,

but does not rotate!

– takes approx. 30 s

– is completed when

c

is on again

5. Inhibit controller

^ 7−48

1

Start identification

·

V/f−rated frequency (C0015), slip

compensation (C0021) and motor stator

inductivity (C0092) are calculated and saved.

·

The motor stator resistance (C0084) = total

resistance of motor cable and motor is

measured and saved