3 speed control, Application examples, Speed control – Lenze 8200 motec frequency inverter 0.25kW-7.5kW User Manual

Page 195: Speed sensor requirements

Application examples

Speed control

13−10

l

EDB82MV752 EN 5.2

13.3

Speed control

Tip!

Lenze three−phase AC motors and Lenze geared motors can be supplied with the Lenze pulse

encoder ITD21 (512/2048 increments, HTL output signals). This makes it possible to set up a

two−track speed feedback (tracks A and B) when using the application I/O function module.

Example

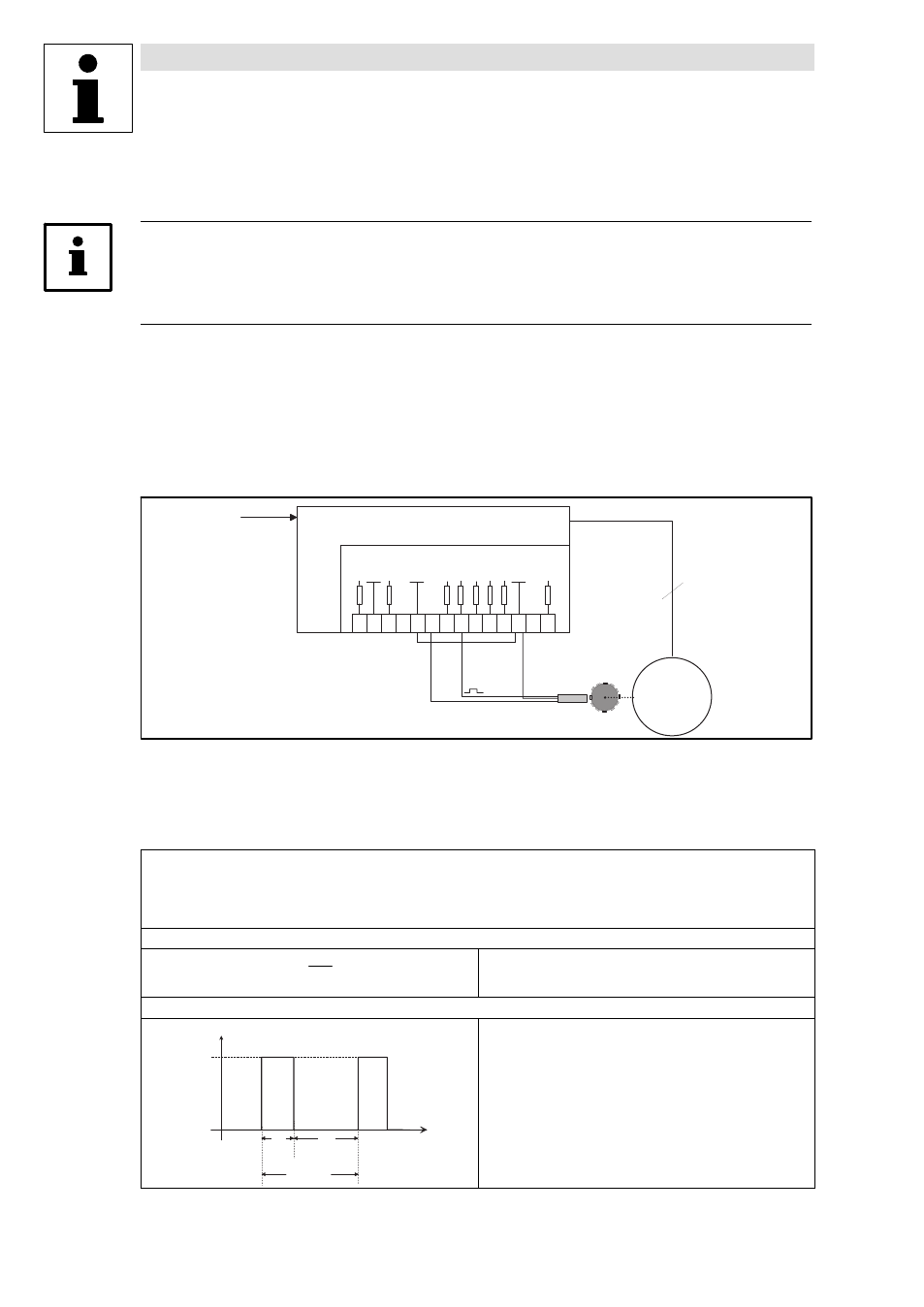

Speed control with inductive single−track three−wire sensor

The speed control is designed to correct the deviation between the actual speed and the setpoint

speed caused by the effect of the load (motive and generative).

In order to detect the motor speed, the inductive sensor scans e.g. a gear, a metallic fan impeller or

cam. Scanning should take place directly on the motor or within the machine.

6 2

8

9

7

2 0 2 8 E 1

A 1

E 4

E 3

E 2

3 9

+ 5 V

G N D 2

8 2 0 0

M

3 ~

3

7

5 9

G N D 1

+ 2 0 V

G N D 1

Q

R

S t a n d a r d - I / O

Fig. 13−4

Speed control with three−wire sensor

setpoint

three−wire sensor

8200:

8200 motec or 8200 vector

Speed sensor requirements

·

The maximum frequency of inductive sensors generally ranges from 1 ... 6 kHz depending on the type.

·

At the detection point, the number of attenuation cams per revolution must ensure an output frequency of the sensor as high as possible.

·

The control dynamics will be sufficient if the output frequency (f

act

) is > 0.5 kHz at rated speed.

·

If the current consumption of the sensor is not higher than the value permitted at X3/20, a three−wire sensor can be directly connected to

the controller.

Output frequency calculation

f

act

+

z

@ n

60

z = number of cams per revolution

n = speed at the detection point [rpm]

f

act

= output frequency of the sensor in [Hz]

Permissible pulse shape at X3/E1

T ³ 1 0 0 m s

T e

T a

1 5 V

U

E 1

t

0

0

·

Te = on (HIGH)

·

Ta = off (LOW)

Permissible level range:

·

LOW: 0 ... +3 V

·

HIGH: +12 ... +30 V

Permissible range of the scanning ratio

·

Te : Ta = 1 : 1 to Te : Ta = 1 : 5

Tip!

You can use every speed sensor which meets the level and scanning

ratio requirements.