Frame 11 fan system replacement procedures, Remove power from the drive – Rockwell Automation 20Y PowerFlex 700H, 700S, and 700AFE Drive Fan Systems, Frames 9...14 User Manual

Page 91

Rockwell Automation Publication PFLEX-IN029B-EN-P - August 2014

91

PowerFlex 700H and 700S Drives - Frame 11 Procedures

Chapter 3

Frame 11 Fan System

Replacement Procedures

Replacement procedures for these frame 11 fan system parts are included in this

chapter.

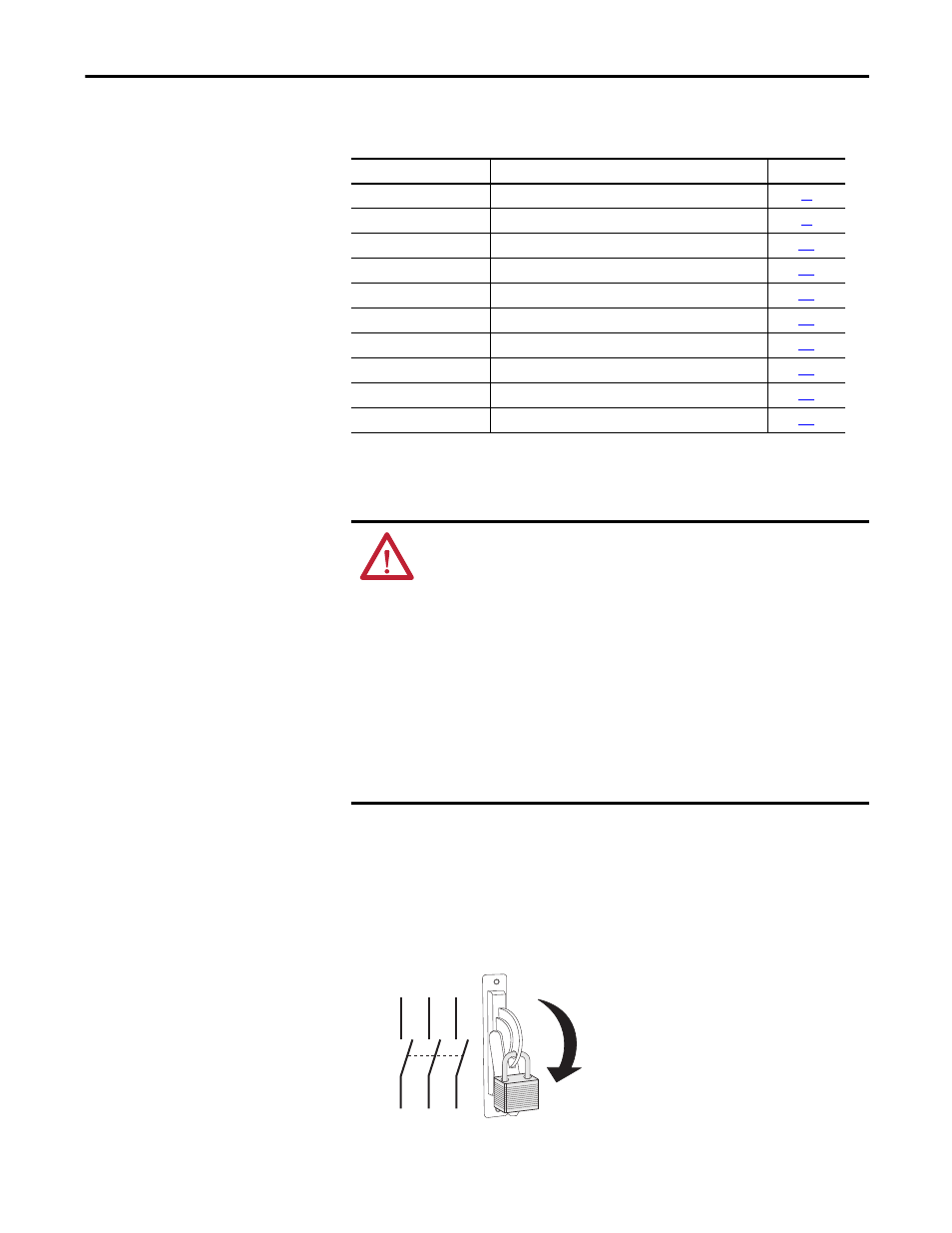

Remove Power from the Drive

1.

Turn off and lock out input power.

2.

Wait five minutes.

3.

Check the DC bus voltage at the Power Terminal Block by measuring

between the +DC and -DC terminals, between the +DC terminal and the

chassis, and between the -DC terminal and the chassis. The voltage must

be zero for all three measurements.

Cat. No.

Part Description

Page

20-VB00299

Main AC fan inverter circuit board

20-FR10845

Output transformer assembly for AC fan inverter (right side)

(1)

(1) This assembly does not include the main fan inverter circuit board.

SK-H1-DCFANBD1

Main DC fan power supply circuit board

SK-H1-DCFANRETROFIT-F11

AC to DC fan system retrofit kit

SK-H1-FANCAP-F1012

Main AC fan capacitor (7

μF) kit

20-PP01080

230 W main AC fan assembly

SK-Y1-DCFAN1

Main DC fan assembly

20-PP01096

60 mm cooling fan for the ASIC board assembly

20-PP20202

Fuse for fan system

20-PP20300

Fuse holder for main fan system fuses

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the bus

capacitors has discharged completely before servicing. Check the DC bus voltage

at the Power Terminal Block by measuring between the +DC and -DC terminals,

between the +DC terminal and the chassis, and between the -DC terminal and

the chassis. The voltage must be zero for all three measurements.

Remove power before making or breaking cable connections. When you remove or

insert a cable connector with power applied, an electrical arc may occur. An

electrical arc can cause personal injury or property damage by:

• sending an erroneous signal to your system’s field devices, causing unintended

machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the module and its

mating connector. Worn contacts may create electrical resistance.

L1

L2

L3

O

I