3 instrument cluster, Instrument cluster, Caution – SkyTrak 8042 Service Manual User Manual

Page 801

Electrical System

9.210

Model 8042, 10042, 10054 Legacy

Rev. 10/03

b. Disassembly

DO NOT disassemble the back-up alarm. Replace a

defective or faulty alarm with a new part.

c. Inspection and Replacement

Inspect the wiring harness connector and alarm terminals

for continuity and shorting. Replace a defective or faulty

alarm with a new part.

d. Installation and Testing

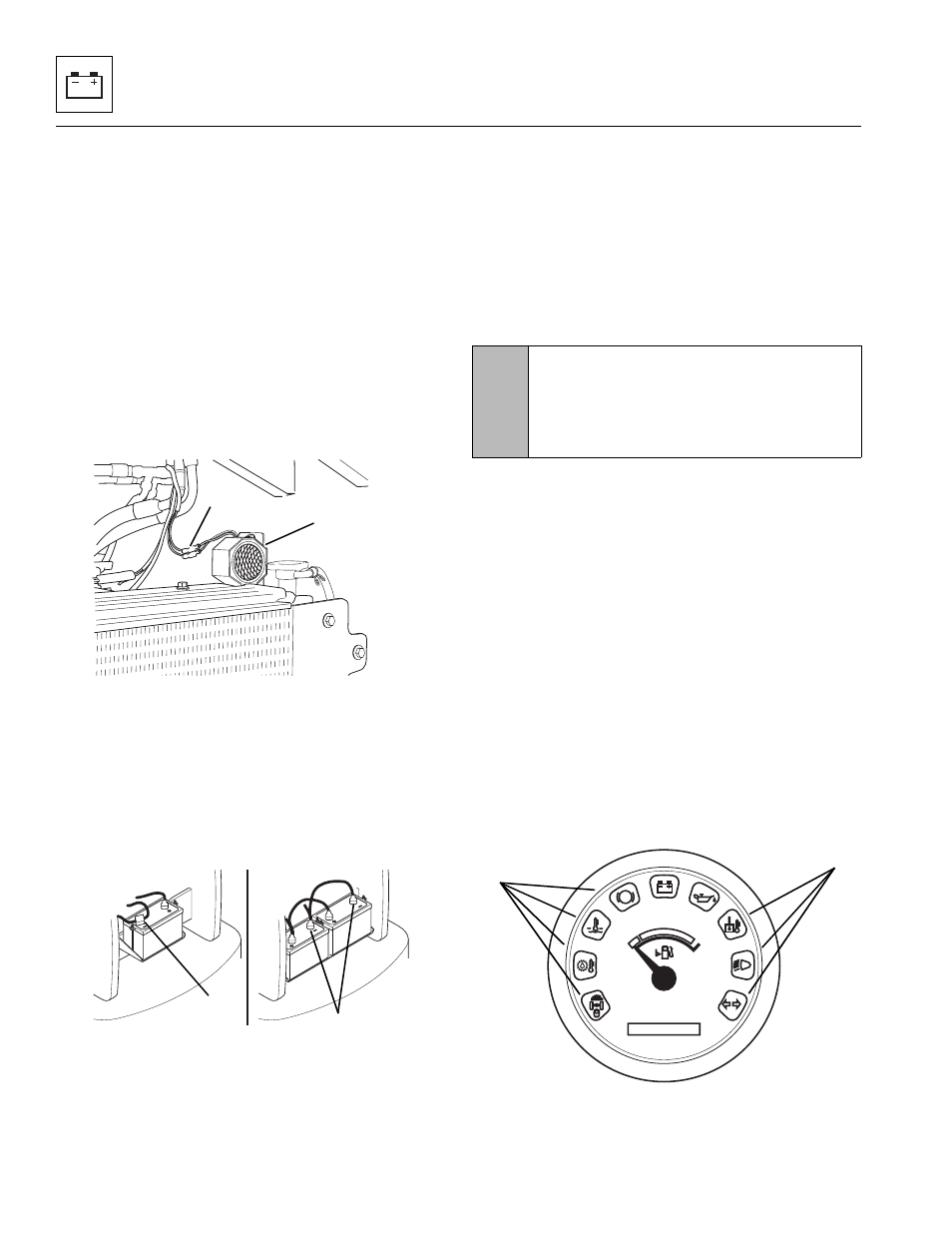

1. Position the back-up alarm (1) onto the 1/4-20 studs

located on the inside frame wall at the rear of the

vehicle. Secure with two lockwashers and 1/4-20

nuts.

2. Connect the wiring harness connector lead (2) to the

back-up alarm.

3. If the vehicle has one battery, connect the

negative (-) battery cable to the negative (-) battery

terminal (3).

If the vehicle has dual batteries, connect both

negative battery cables to both negative (-) battery

terminals (4).

4. Test the alarm by turning the ignition key switch to

the RUN position and shifting the travel select lever

into the REVERSE position. The back-up alarm

should sound.

9.11.3

Instrument Cluster

The information under this heading deals mainly with the

description and function of each indicator in the

operator’s instrument cluster. Appropriate service

procedures for each circuit, as applicable, appear

elsewhere in this section of the manual.

The instrument cluster is of solid-state, printed circuit

design, and contains one

wiring terminal and a display

panel that provides overall monitoring of vehicle functions

and status.

Prevent the instrument cluster from coming into contact

with static or other electrical sources. When washing the

vehicle, keep spray away from the operator’s display

panel. Replace a defective, malfunctioning or faulty panel

with a new unit.

The operator’s display panel provides important

information in a “user friendly” design with easily

recognizable graphic and alpha-numeric indicators. The

panel provides information the operator needs to know

about vehicle and engine functions.

When testing circuits connected to the instrument cluster,

disconnect the harness connector and test the harness

side only.

a. Power-Up Lights

When the ignition key switch is turned to power up the

vehicle, all lights in the instrument cluster (5 and 6) will

illuminate for three seconds as a test function.

MH29402

1

2

MH4890

3

4

CAUTION:

Before performing ANY

welding on vehicle, disconnect the negative (-)

battery cable at the negative (-) battery terminal.

Failure to remove the negative (-) battery cable

will result in damage to vehicle electronic systems.

0000 00

P

OH1810

5

6