4 effective ground connections, 5 wiring harnesses, 1 removal and replacement – SkyTrak 8042 Service Manual User Manual

Page 604: 2 disassembly, Effective ground connections, Wiring harnesses, Removal and replacement, Disassembly

9.13

Model 8042, 10042, 10054 Legacy

Rev. 10/03

Electrical System

9.4

EFFECTIVE GROUND CONNECTIONS

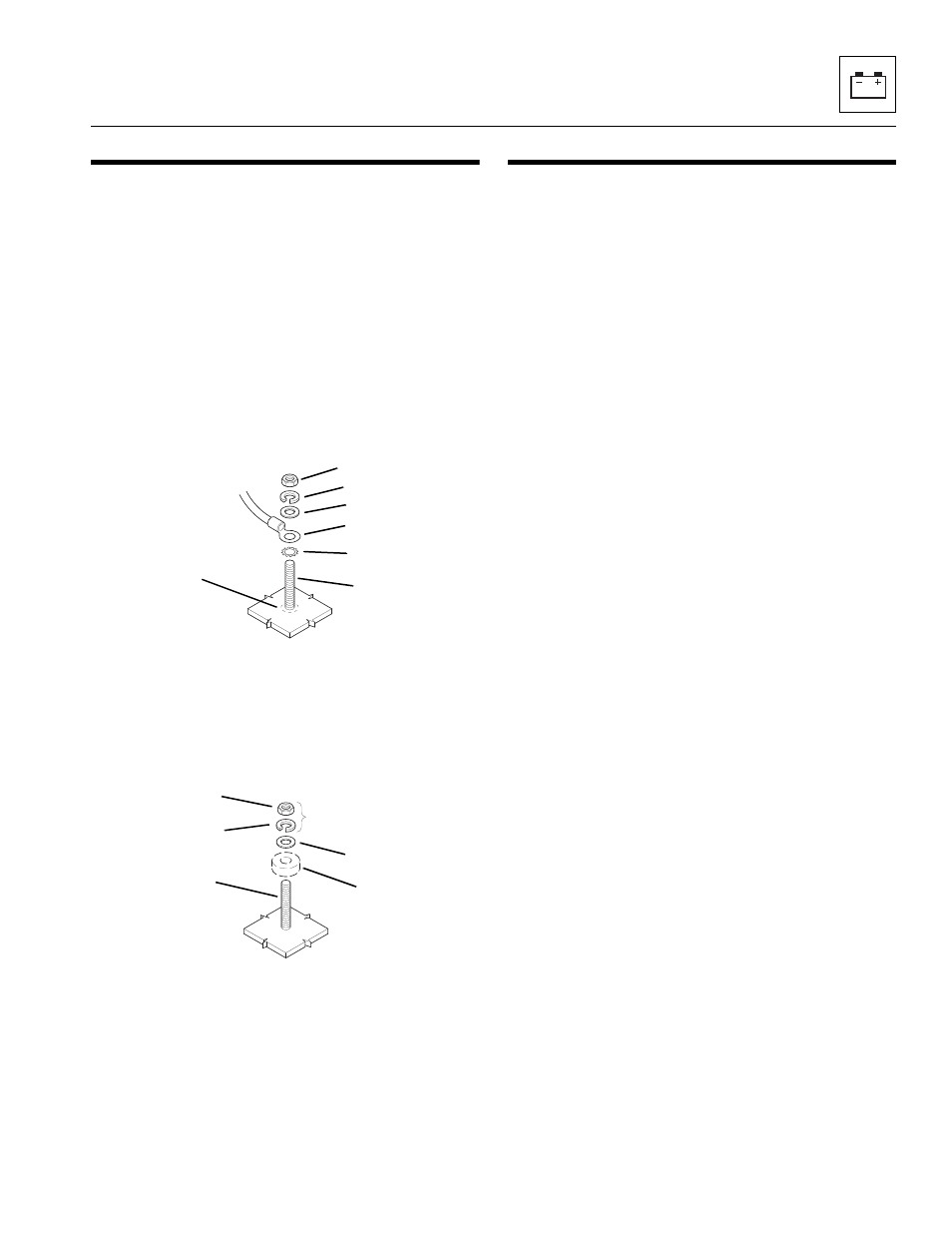

1. Effective ground connections are essential to the

efficient operation of electrical components. If an

inadequate ground is suspected or determined,

establishing another ground may be desired. Also, in

the event a factory-authorized accessory is being

installed, it is necessary to follow the proper

sequence for providing an electrical ground. The

sequence for installing or attaching a component to

an electrical ground to a stud, bolt or capscrew (4) is

to provide a clean surface by eliminating paint and

rust from the area around the base of the stud (5).

Install a tooth type lockwasher (6), electrical wire

connector (7), flat washer (8), tooth or slot-type

lockwasher (9) and hex nut or locknut (10).

2. When an electrical component (11) is to be

grounded, eliminate paint and rust from around the

stud, bolt or capscrew (12), install a flat washer (13),

tooth type or slot-type lockwasher, or locking nut with

slotted type lockwasher (14) and hex nut or

locknut (15).

9.5

WIRING HARNESSES

For Serial Numbers 8042, 13198-18990,

10042, 13198-19030 & 10054 13189-19079; wiring on

the vehicle is contained within two separate wiring

harnesses, an engine harness and a cab harness.

For Serial Numbers 8042, 18991 - 19987,

10042 19031 - 19987, 10054, 19080 - 19987 And

8042/10042/10054, 0160002332 & After; wiring on the

vehicle is contained within three separate wiring

harnesses, an engine harness, ECM cab harness and a

cab harness.

A harness consists of black-nylon woven braiding,

providing a protective cover to bundle numerous wiring

groups, splices, terminals, connectors and (where

applicable) diodes. Each harness is identified with a part

number when the vehicle leaves the factory.

Each wire is identified by a wire number on each end of

the individual wire and by the color and gauge size of the

wire. The wire numbers are also identified on the

appropriate electrical schematic. All circuits have been

electrically tested for continuity, and all diodes have been

tested for correct biasing. Where several individual

connectors appear, the wiring leading to a particular

connector can help identify the specific circuit. For some

circuits, a colored band (tie wrap) is present, and is

affixed to the connector wiring and used as a color-code

indicator. If wiring needs to be replaced, use the correct

gauge size wiring. NEVER replace a wire with a smaller

gauge wire.

9.5.1

Removal and Replacement

Remove a wiring harness only if damaged or unusable.

Install a new harness one terminal at a time, as the old

harness is removed. Label or tag the terminal locations of

all wires, harness clips, tie wraps and conduit, as the old

harness is removed, to allow correct installation of the

new harness.

9.5.2

Disassembly

Disassembly of the wiring harness is not recommended

due to the precise arrangement of wires and splice

requirements. If it becomes necessary to replace wires,

use the correct gauge size wiring, and NEVER replace a

wire with a smaller gauge wire.

MA0871

4

5

6

7

8

9

10

MA0881

11

12

13

14

15