D ( 5 ), Od ( 4, Ng ( 15 – SkyTrak 8042 Service Manual User Manual

Page 578: 21 ) t, Be ( 6 ), Od ( 4 ), E ( 24 ), Nd ( 5 )

8.163

Model 8042, 10042, 10054 Legacy

Rev. 10/03

Hydraulic System

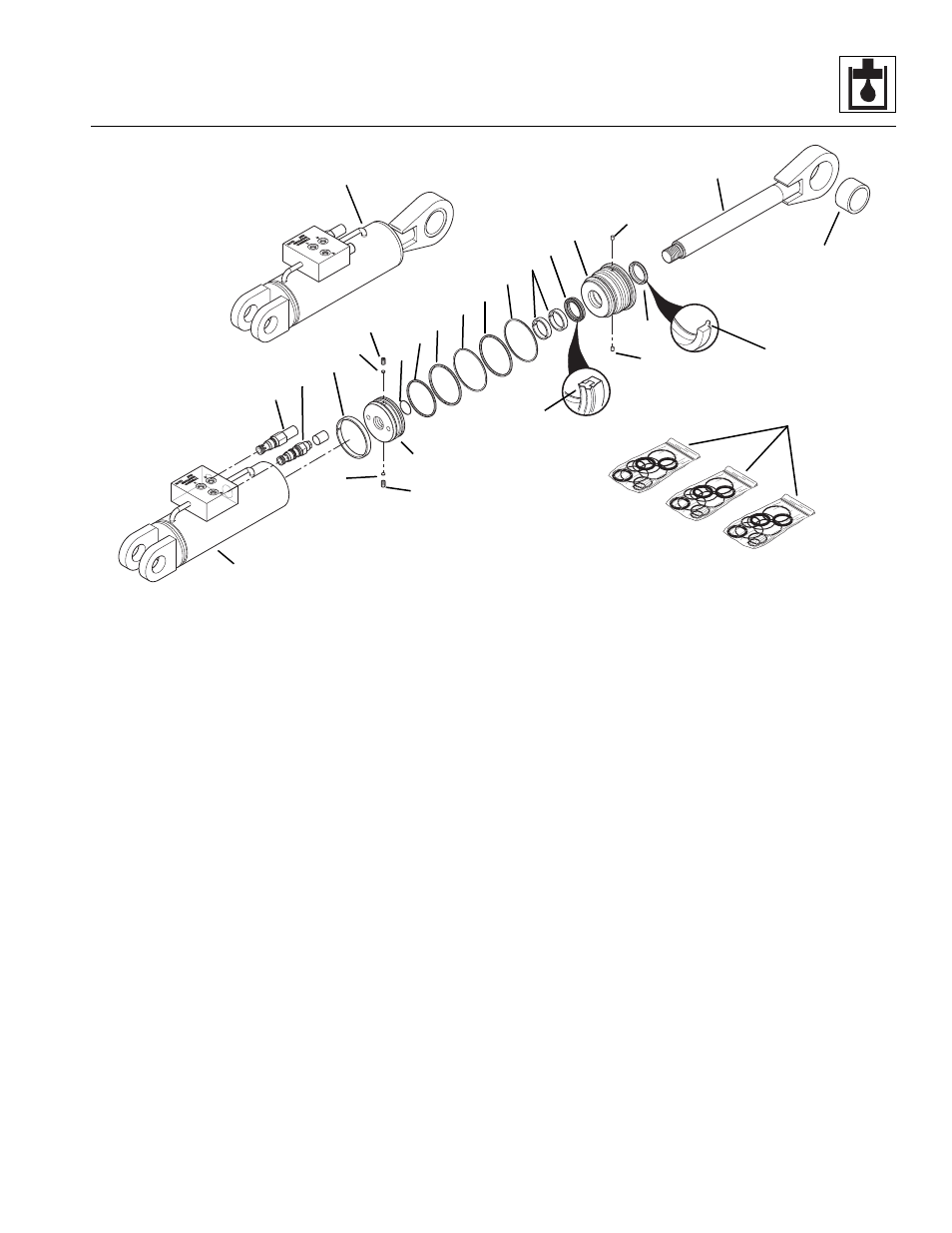

7. Install a new piston square seal (10), square ring

(11) and precision wearband (12) onto the piston (7).

8. Apply Loctite Primer “T” and Threadlocker #271

(red) to the threads of the piston (7) in accordance

with Loctite instructions. Thread the piston (7) onto

the rod (4) and torque to 440-500 ft-lb (597-678 Nm).

9. Install two new setscrews (8) with locking inserts (9)

into their holes in the piston (7). Torque to 85-95 lb-ft

(115-124 Nm).

IMPORTANT: Avoid using excess force when clamping

the cylinder in a vise. Apply only enough force to hold the

cylinder securely. Excessive force can damage the

cylinder tube (6).

10. Place the cylinder tube (6) in a soft-jawed vise or

other acceptable holding equipment if possible.

11. Lubricate the piston (7), head gland (5) and the

inside of the tube (6) with clean, filtered hydraulic oil.

12. Apply a compression sleeve or other suitable tool to

the head gland (5) in order to compress the o-rings

(15 and 17).

IMPORTANT: When sliding the rod and piston assembly

in the tube, prevent the threaded end of the tube from

damaging the piston (7). Keep the rod centered within

the tube to help prevent binding.

13. Carefully insert the rod (4) with all attachments

straight into the tube (6). Use a pin spanner wrench

to thread the head gland into the tube. Torque the

head gland to 250-300 lb-ft (339-407 Nm). Remove

the compression tool.

14. Using new oiled o-rings, install the counterbalance

valve (2) and direct-acting relief valve (3). Lubricate

the cartridge and valve with clean, filtered hydraulic

oil. Torque the valves to 35-40 lb-ft (47-54 Nm).

15. Test the cylinder at low operating pressure (100 psi

or 7 bar). Verify that the piston and rod move freely

in both directions.

16. Increase the operating pressure to the maximum for

the cylinder (3000 psi or 207 bar). Verify that the

piston and rod move freely in both directions.

17. Retract the piston fully and cap the hydraulic hose

ports. Install the cylinder on the carriage.

18. If the bearing (22) requires replacement, support the

rod (4) in a soft-jawed vise or other suitable holding

device. Carefully press a new bearing into the rod

eyelet.

MT1911

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

20

21

22

23

24

16

17

18

19