2 drive shaft maintenance, 3 drive shaft removal, Drive shaft maintenance – SkyTrak 8042 Service Manual User Manual

Page 291: Drive shaft removal, Section 5.4.3, “drive shaft removal.”)

Axles, Drive Shafts, Wheels and Tires

5.18

Model 8042, 10042, 10054 Legacy

Rev. 10/03

5.4.2

Drive Shaft Maintenance

Refer to the appropriate owners/operators manual for

information regarding the lubrication of the grease fittings

on the drive shafts.

5.4.3

Drive Shaft Removal

IMPORTANT: To help ensure optimum performance, the

drive shaft assemblies are specially balanced as a unit at

the factory. When servicing any flange yoke, slip yoke or

drive shaft tube, order a complete assembly if

components are bent or damaged. Refer to the appropriate

parts manual for ordering information.

Note: The drive shaft assemblies are balanced

assemblies. Mark the yoke and axle, transmission,

transfer case, and the shaft and slip yoke so that these

components can be returned to their original positions

when reinstalled. Yokes at both ends of the drive shaft

must be in the same plane to help prevent excessive

vibration.

a. Transmission-to-Axle Drive Shafts

1. Level the vehicle, ground the carriage, place the travel

select lever in the (N) NEUTRAL position, place the

neutral lock lever in the (N) NEUTRAL LOCK

position, engage the parking brake switch and shut

the engine OFF.

2. Place an Accident Prevention Tag on both the

ignition key switch and steering wheel, stating that

the vehicle should not be operated. (Refer to Section

1.5, “Accident Prevention Tags.”)

3. Unlock and open the right, left and rear engine

compartment access doors. Allow the engine,

transmission and hydraulic fluid to cool.

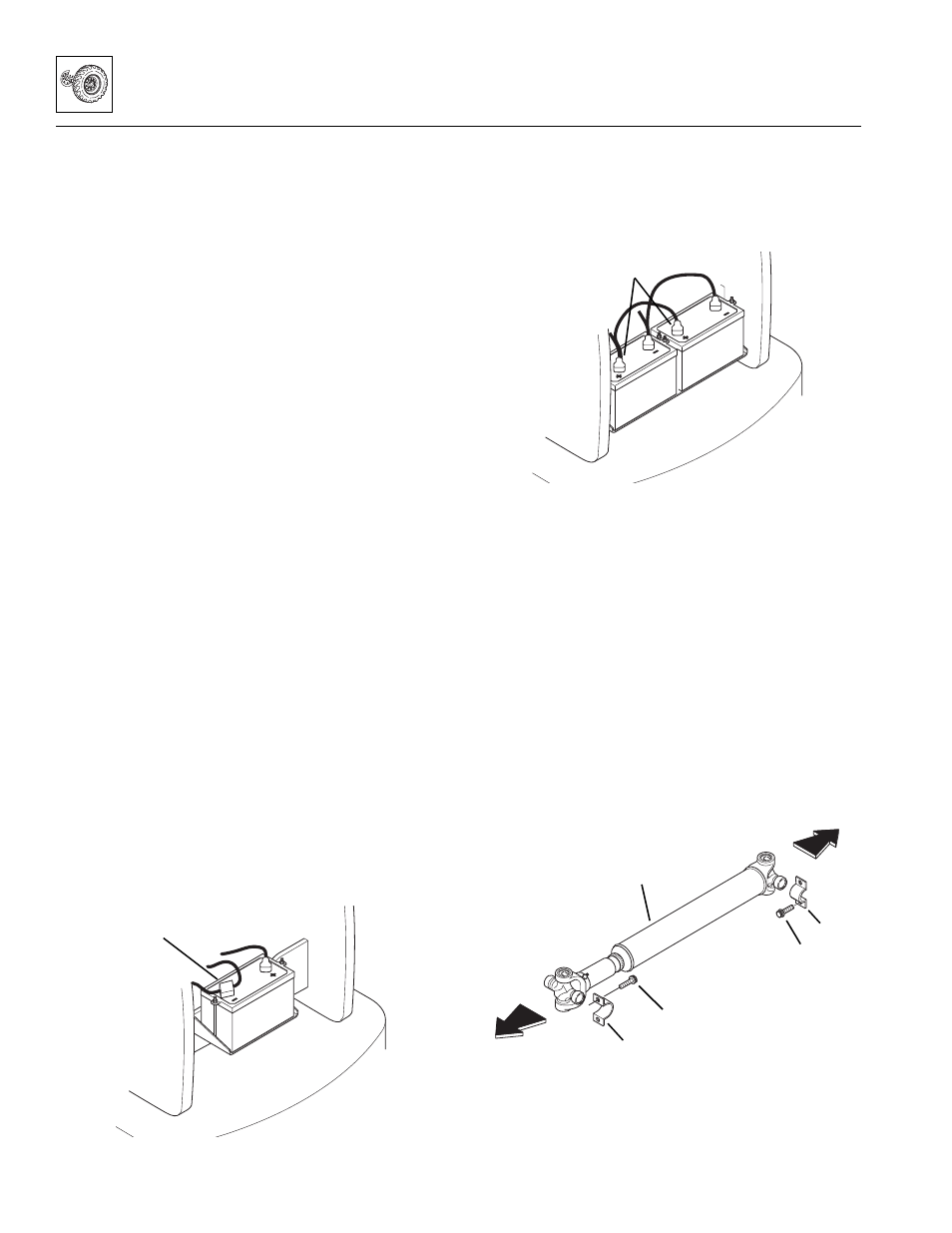

4. (SN 18990 (8042), 19030 (10042), 19079 (10054) &

Before Only) Disconnect the battery negative (-)

ground cable (1) at the battery negative (-) terminal

to prevent the engine from starting accidentally.

5. (SN 18991 (8042), 19031 (10042), 19080 (10054) &

After Only) Disconnect the battery negative (-)

ground cables (2) at the battery negative (-)

terminals to prevent the engine from starting

accidentally.

6. The drive shaft assembly is a balanced assembly.

Mark the yoke and axle, transmission and the shaft

and slip yoke so that these components can be

returned to their original positions when reinstalled.

Yokes at both ends of the drive shaft must be in the

same plane to help prevent excessive vibration.

7. Remove the four 12-point capscrews (3) and two

straps (4) securing the bearing cross to the

transmission output shaft flange.

8. Remove the four capscrews (5) and two straps (6)

securing the bearing crosses to the axle.

9. Remove the front drive shaft assembly (7).

10. Repeat Steps 6 thru 9 to remove the rear drive shaft.

OH2420

1

MH4440

2

MT0350

To

Axle

To Transmis-

sion

3

4

5

6

7