SkyTrak 8042 Service Manual User Manual

Page 519

Hydraulic System

8.104

Model 8042, 10042, 10054 Legacy

Rev. 10/03

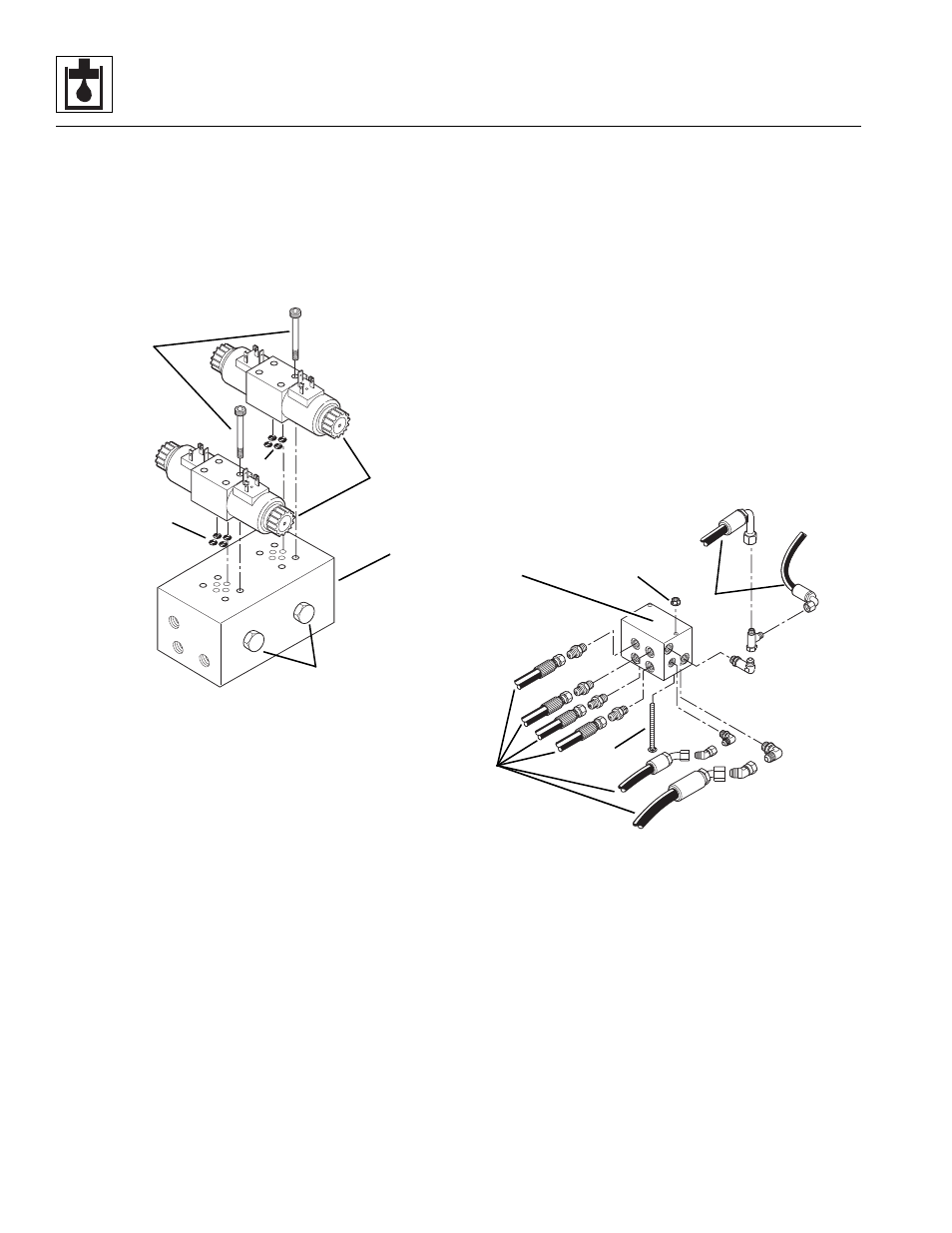

b. Outrigger Valve Disassembly, Cleaning,

Inspection and Assembly

1. Place the outrigger valve assembly on a suitable

work surface.

2. Remove the solenoid valve assemblies (1) from the

outrigger valve (2) by removing the four socket head

capscrews (3). Discard the four o-rings (4).

3. Remove the shuttle cartridges (5) from the outrigger

valve (2).

4. Clean all components with a suitable cleaner before

inspection.

5. Inspect the solenoid cartridges for proper operation.

Check by shifting the spool to ensure that it is

functioning properly. Check that the spring is intact.

Inspect the cartridge interior for contamination.

6. Inspect internal passageways of the outrigger valve

for wear, damage, etc. If inner surfaces of the valve

DO NOT display an ultra-smooth, polished finish, or

components are damaged in any way, replace the

valve or appropriate part. Often, dirty hydraulic fluid

causes failure of internal seals and damage to the

polished surfaces within the secondary function

manifold.

Note: ALWAYS replace seals, o-rings, gaskets, etc.,

with new parts to help ensure proper sealing and

operation. Lubricate seals and o-rings with clean

hydraulic oil.

7. Install the shuttle cartridges (5) into the outrigger

valve (2). Torque to 35 lb-ft (48 Nm).

8. Attach the solenoid assemblies (1) to the outrigger

valve (2) using four new, oiled o-rings (4) and the

four socket head capscrews (3).

c. Outrigger Valve Installation

1. Insert the two carriage bolts (9) through the bottom

of the outrigger valve (7) and loosely attach the hex

flange nuts (8) to the carriage bolts.

2. Position the outrigger valve (7) so that the heads of

the carriage bolts go through the slots in the frame.

Tighten the hex flange nuts.

3. Connect the hydraulic hoses (6), fittings, solenoid

wire terminal leads, etc., to the outrigger valve.

4. Check the routing of all hoses and wiring for sharp

bends or interference with any rotating members,

and install tie wraps and/or protective conduit as

required. Tighten all hose clamps.

P

S

T

MH3880

1

2

3

4

5

MH3760

~

6

7

8

9