SkyTrak 8042 Service Manual User Manual

Page 185

Boom

3.124

Model 8042, 10042, 10054 Legacy

Rev. 03/04

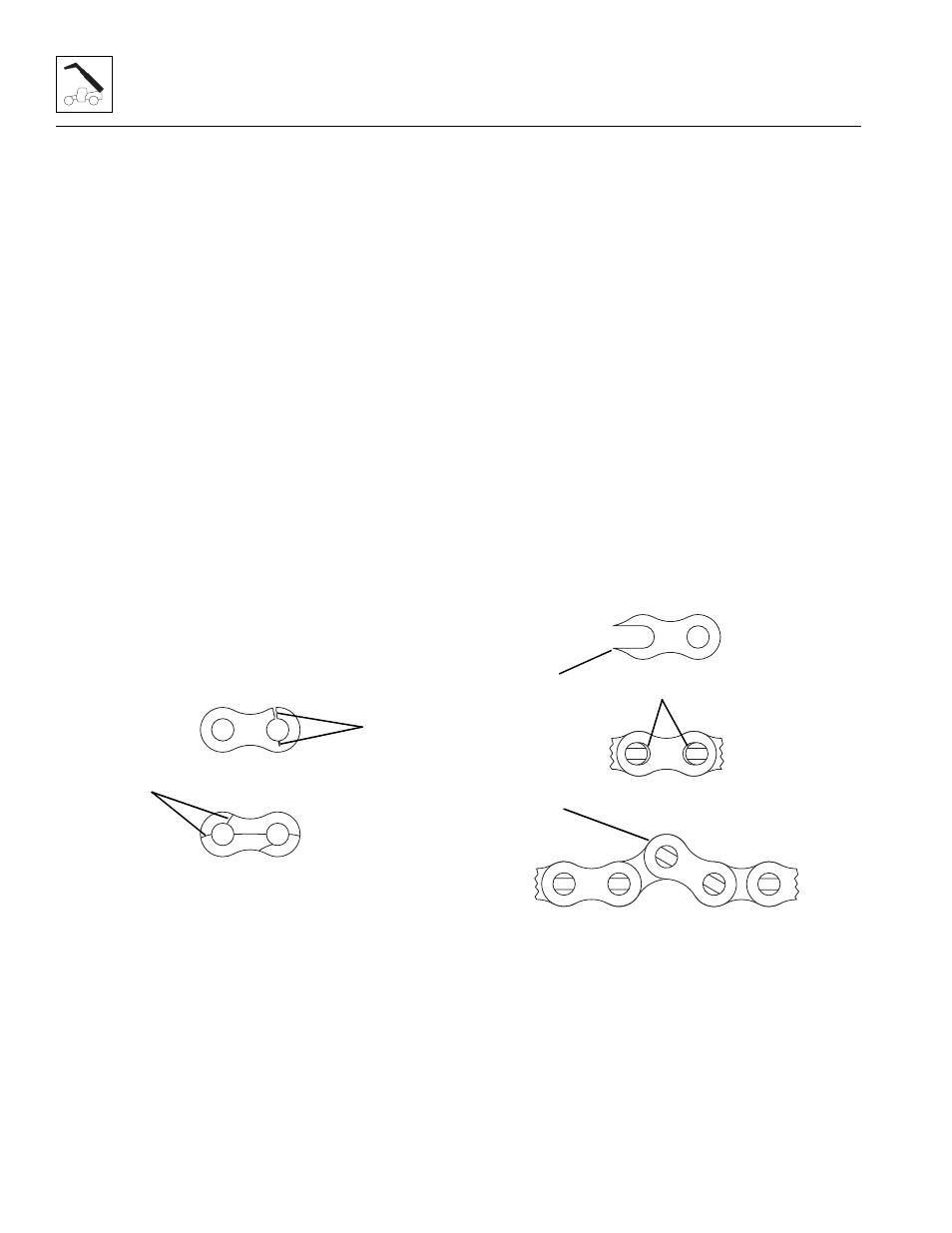

• Fatigue Cracking - Fatigue cracks (1) are a result of

repeated cyclic loading beyond the chain’s

endurance limit. The size of the load and the

frequency of its occurrence are factors which

determine when fatigue failure will occur. The

loading can be continuous or intermittent

(impulse load).

• Stress Corrosion Cracking - The outside link

plates are particularly susceptible to stress corrosion

cracking (2). Like fatigue cracks, these initiate at the

point of highest stress but tend to extend in an

arc-like path between holes in the pin plate. More

than one crack can often appear on a link plate. In

addition to rusting, this condition can be caused by

exposure to an acidic or caustic medium or

atmosphere.

Stress corrosion is an environmentally assisted failure.

Two conditions must be present: corrosive agent and

static stress. In the chain, static stress is present at the

aperture due to the press fit pin. No cyclic motion is

required, and the plates can crack during idle periods.

• Corrosion Fatigue Cracking - Corrosion fatigue

cracks are very similar to fatigue cracks (1) in

appearance. They generally begin at the aperture

and grow perpendicular to the chain pitch line.

Corrosion fatigue is not the same as stress

corrosion. Corrosion fatigue is the combined action

of an aggressive environment and cyclic stress, not

a static stress alone, as in stress corrosion.

Other Modes of Failure

• Ultimate Strength Failure - These types of failures

are caused by overloads far in excess of the design

load. Either fractured plates (3) or enlarged holes (4)

can occur. If either of these failures occurs, the chain

must be replaced immediately. (Refer to Section

3.7.6, “Boom Extend and Retract Chains Removal

and Replacement.”)

Note: The tight joints inspection must be done with the

chain disconnected from the boom. (Refer to Section

3.7.6, “Boom Extend and Retract Chains Removal and

Replacement.”)

• Tight Joints - All joints in the chain must flex freely.

Tight joints (5) resist flexing and increase internal

friction, thus increasing chain tension required to lift

a given load. Increased tension accelerates wear

and fatigue problems.

If the problem is caused by dirt or foreign substance

packed in the joints, clean and lubricate thoroughly

before re-installing the chain.

If the problem is caused by corrosion and rust or bent

pins, replace the chain. (Refer to Section 3.7.6, “Boom

Extend and Retract Chains Removal and Replacement.”)

MM2080

MM2070

1

2

MM2100

MM2110

MM2090

3

4

5